A caution – Carrier 38E User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

This type of fitting is easily repaired if leaks develop.

Frontseat outdoor section service valves after relieving

refrigerant pressure in system. Back locknut off Carrier

Compatible Fitting onto tube. Cut fitting between

threads and 0-ring. Remove tubing section remaining

in threaded portion of fitting. Discard locknut.

Clean, flux and insert new tube end into remaining

portion of Carrier Compatible Fitting. Wrap valve in wet

cloth to prevent damaging valve. Heat and apply low-

temperature solder (430 F [221 C]).

Leaking Sweat Connection — Frontseat service valves

and relieve refrigerant pressure in tubing. Clean and

flux area around leak and apply low-temperature

solder (430 F [221 C]).

Liquid line service valves on all heat pump models

differ from condensing unit valves in that heat pump

connection has 3/8-in. male flare. When making connec

tion, remove flare nut, install it on liquid line prior to

flaring. Flare liquid line using standard flaring tech

niques. Valve also contains piston and retainer. Service

as follows:

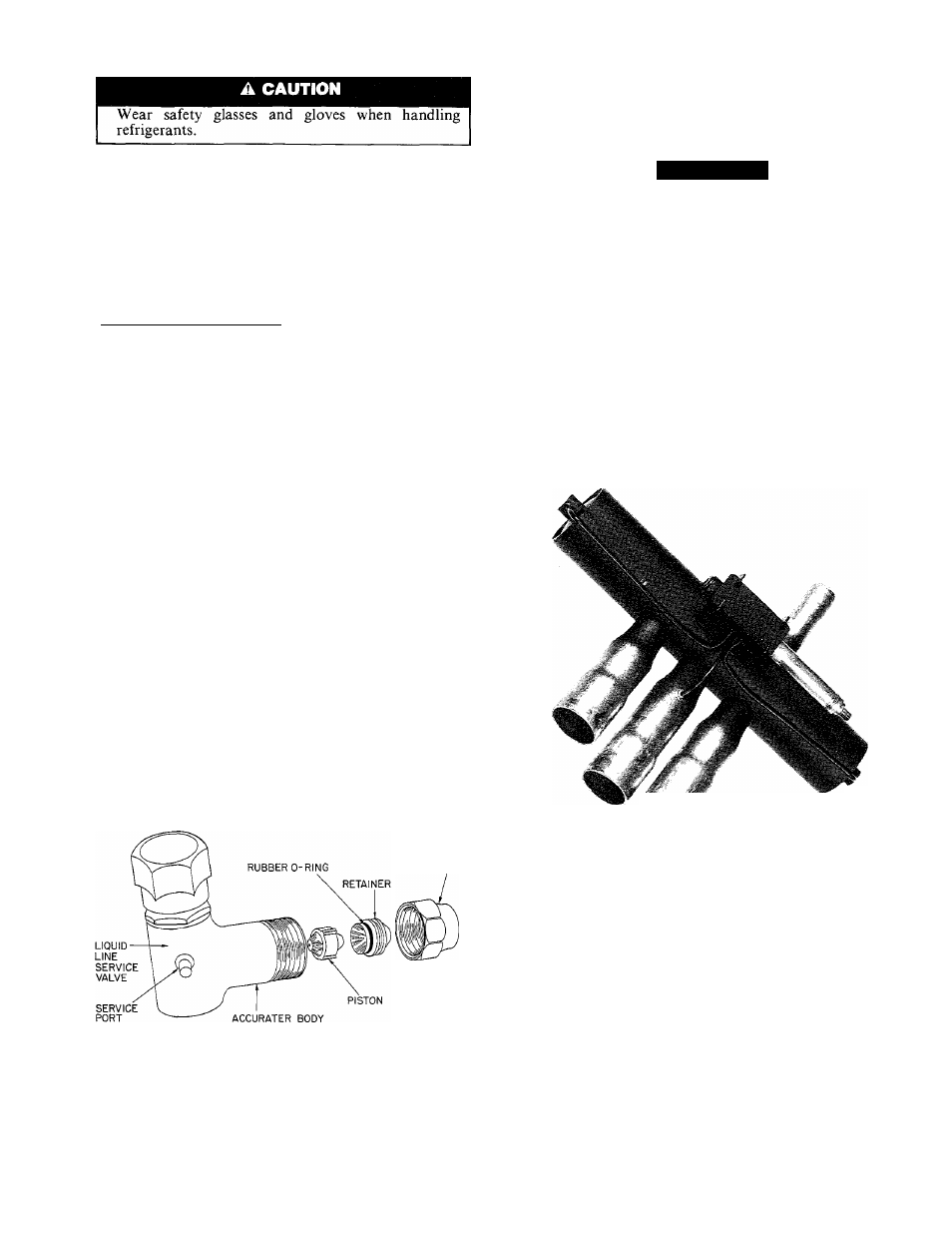

ACCURATER"“ (Bypass Type) COMPONENTS —

(See Fig. 23.) AccuRater piston has a refrigerant metering

hole through it. Retainer forms a stop for piston in

refrigerant bypass mode, and a sealing surface for liquid

line flare connection. To check, clean or replace piston:

1. Shut off power to unit.

2. Pump unit down using Pumpdown Procedure des

cribed in this Service Manual.

3. Remove liquid line flare connection from AccuRater.

4. Pull retainer out of body, being careful not to scratch

flare sealing surface. If retainer does not pull out

easily, carefully use locking pliers to remove it.

5. Slide piston out by inserting a small soft wire, with

small kinks, through metering hole. Do not damage

metering hole, sealing surface around piston cones or

fluted portion of piston.

6. Clean piston refrigerant metering hole.

7. Replace retainer 0-ring (Part No. 99CC501052)

before reassembling bypass-type AccuRater.

FLARE NUT

Fig. 23 — AccuRater™ (Bypass Type) Components

Service valves provide a convenient shutoff valve useful

for certain refrigeration system repairs. System may be

pumped down to make repairs on low side without losing

complete refrigerant charge.

1. Attach pressure gage to suction service valve

gage port.

2. Frontseat liquid line valve.

3. Start unit in cooling mode. Run until suction pressure

reaches 5 psig (35 kPa).

4. Shut unit off. Frontseat suction valve.

5. Vent remaining pressure to atmosphere.

A CAUTION

All outdoor unit coils will hold only factory-supplied

amount of refrigerant. Excess refrigerant may cause

unit to relieve pressure through internal pressure

relief valve (indicated by sudden rise of suction

pressure) before suction pressure reaches 5 psig

(35 kPa), If this occurs, shut off unit immediately,

frontseat suction valve, and vent remaining pressure

to atmosphere.

REVERSING VALVE — (See Fig. 24.) In heat pumps,

changeover between heating and cooling modes is

accomplished with a valve that reverses flow of refrig

erant in system. This reversing valve device is easy to

troubleshoot and replace. The reversing valve solenoid

can be checked with power off with an ohmmeter. Check

for continuity and shorting to ground. With control

circuit (24 v) power on, check for correct voltage at

solenoid coil. Check for burned or overheated solenoid.

Fig. 24 — Reversing Valve

With unit operating, other items can be checked, such

as frost or condensate water on refrigerant lines.

The sound made by a reversing valve, as it begins or

ends defrost, is a loud whooshing noise, as reversing

valve reverses, and pressures in system equalize. An

experienced service person detects this sound and uses it

as a valuable troubleshooting tool.

Using a remote measuring device, check inlet and outlet

line temperatures. Do not touch lines. If reversing valve

is operating normally, inlet and outlet temperatures on

appropriate lines should be close. Any difference would

be due to heat loss or gain across valve body. Tempera

tures are best checked with a remote reading electronic-

type thermometer with multiple probes. Route thermo

couple leads to inside of coil area through service valve

mounting plate area underneath coil. Figures 25 and 26

show test points on reversing valve for recording tempera

tures. Insulate points for more accurate reading.

17