A warning – Carrier 38E User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

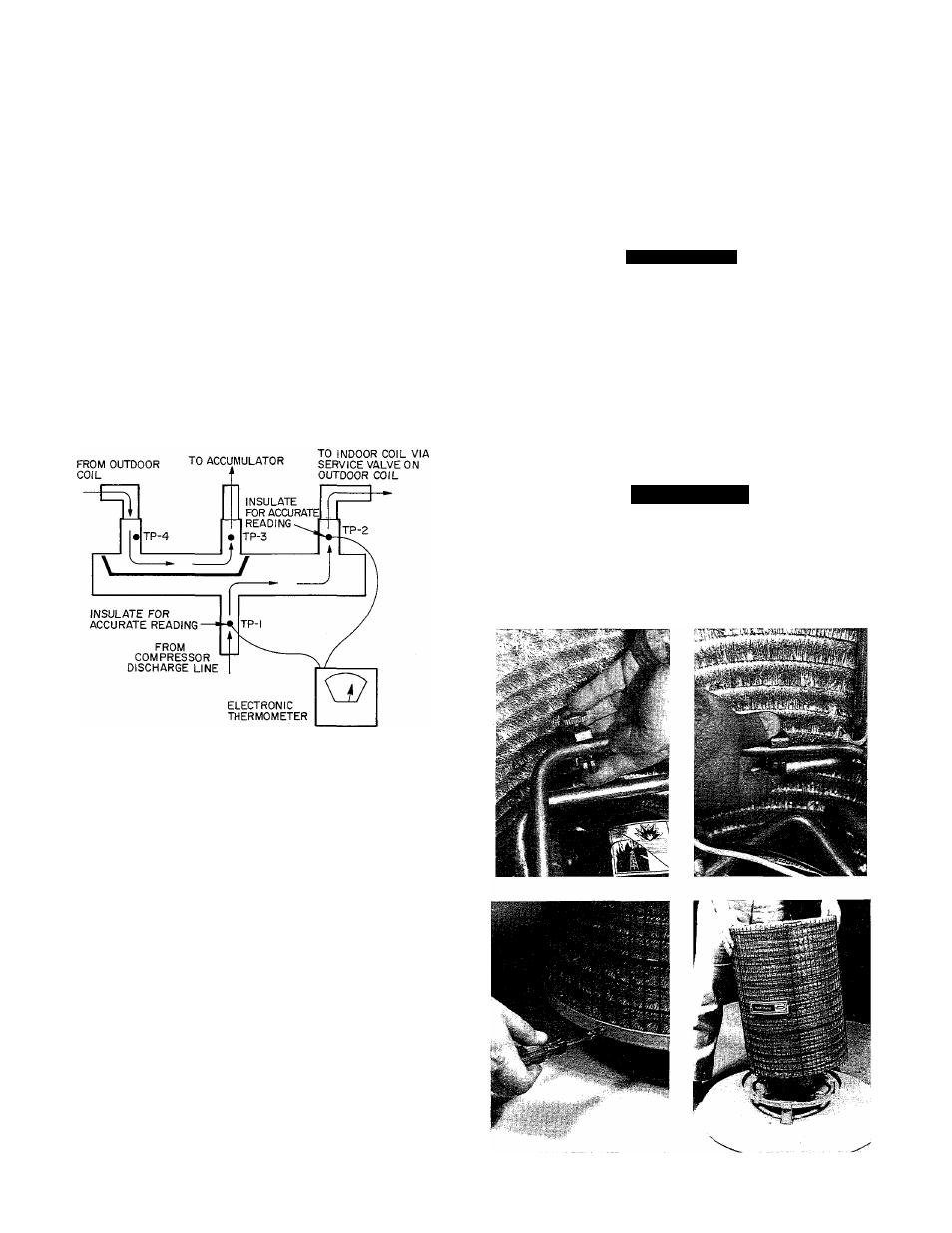

TO OUTDOOR

COIL

TP-4

FROM INDOOR COIL VIA

SERVICE VALVE ON

OUTDOOR COIL

TO

ACCUMULATOR

TP-3

TP-2

J

TP-1

FROM

COMPRESSOR

DISCHARGE LINE

TP = Test Point

TP-2 and TP-3 Cool or cold, may have condensation or frost on both lines

entering valve body, 5F to 10F maximum temperature difference across

normally operating valve.

TP-1 and TP-4 Hot, 5 F to 10 F maximum temperature difference across

normally operating valve.

Fig. 25 — Reversing Valve (Cooling Mode or

Defrost Mode, Solenoid Energized)

TP = Test Point

TP-1 and TP-2 Hot, 5F to 10F maximum temperature difference across

normally operating valve.

TP-3 and TP-4 Cool or cold, may have condensation or frost on both lines

into valve body, 5F to 10 F maximum temperature difference across

normally operating valve.

Fig. 26 — Reversing Valve (Heating Mode

Solenoid De-Energized)

If valve is defective: Shut off all power to unit. Some

smaller sizes may require coil to be removed to gain access

to reversing valve. See appropriate coil removal section.

Remove all charge from system.

Remove solenoid coil from valve body. Remove valve

by cutting it from system with tubing cutter. Repair

person should cut in such a way that stubs can be easily

rebrazed back into system. Do not use hacksaw. This

introduces chips into system that cause failure. After

defective valve is removed, wrap it in wet rag and care

fully unbraze stubs. Save stubs for future use. Because

defective valve is not overheated, it can be analyzed for

cause of failure when it is returned.

Braze new valve onto used stubs. Keep stubs oriented

correctly. Scratch corresponding matching marks on old

valve and stubs, and new valve body, to aid in lining up

new valve properly. When brazing stubs into valve,

protect valve body with wet rag to prevent overheating.

Use slip couplings to install new valve with stubs back

into system. Even if stubs are long, wrap valve with a wet

rag to prevent overheating.

After valve is brazed in, check for leaks. Evacuate and

charge system. Operate system in both modes several

times to be sure valve functions properly.

COIL REMOVAL — (See Fig. 27.) Coils on this family

of units are ea.sy to remove if required for compressor

removal, or to replace coil. Shut off all power to unit.

Remove refrigerant from system through service valves.

A CAUTION

Wear safety glasses and gloves when handling refrig

erants. If unit is equipped with a louvered casing,

refer to Cabinet Servicing for casing removal

procedure.

1. Remove discharge grille by removing 3 (015-030) or

6 (036-060) screws.

2. Remove control box cover (3 screws).

3. Remove fan/motor/orifice assembly by removing, 4

screws (2 in top of control box). Prior to lifting out

assembly, unplug motor wires from base of motor.

A WARNING

Avoid possibility of fire and personal injury by

cutting tubing.

4. Use midget tubing cutter to cut liquid and vapor lines

at both sides of coil. Cut in convenient location for

easy reassembly with copper slip couplings.

Fig. 27 — Removing Outdoor Coil

18