A caution, Refrigeration system – Carrier 38E User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

resistance from each reading. If any reading is within

± 20% of known resistance, motor is probably normal.

Usually a considerable difference in reading is noted if a

turn-to-turn short is present.

SYSTEM CLEAN-UP AFTER BURN-OUT

A

CAUTION

Turn off all power to unit before proceeding. Wear

safety glasses and gloves when handling refrigerants.

Acids formed as a result of motor burn-out can

cause burns.

Some compressor electrical failures can cause motor

to burn. When this occurs, byproducts of burn, which

include sludge, carbon and acids contaminate system.

If burn-out is severe enough, system must be cleaned

before replacement compressor is installed. The 2 types

of motor burn-out can be classified as mild or severe.

In mild burn-out, there is little or no odor detectable.

Compressor oil is clear or slightly discolored. An acid

test of compressor oil will be negative. This type of failure

is treated the same as mechanical failure. Liquid line

strainer should be removed and liquid line filter drier

installed.

In a severe burn-out, there is a strong, pungent, rotten

egg odor. Compressor oil is very dark. Evidence of burn

ing may be present in tubing connected to compressor.

An acid test of compressor oil will be positive. Complete

system must be reverse-flushed with refrigerant. Accu-

RateT“ or TXV must be cleaned or replaced. In a heat

pump, accumulator and reversing valve are replaced.

These components are also removed and bypassed during

reverse-flushing procedure. Remove and discard liquid

line strainer. After system is reassembled, install liquid

and suction line filter driers, run system for 2 hours.

Discard both driers, install new liquid line drier only.

COMPRESSOR REMOVAL AND REPLACEMENT

— Once it is determined that compressor has failed and

the reason established, compressor must be changed.

Shut off all power to unit. Remove all refrigerant

from system until pressure gage reads 0 psi.

A CAUTION

Wear safety glasses and gloves when handling refrig

erants. Disconnect electrical leads from compressor.

Disconnect or remove crankcase heater. Remove

compressor holddown bolts.

Cut compressor from system with tubing cutters. Do

not use brazing torch for compressor removal. Oil vapor

may ignite when compressor is disconnected. Scratch

matching marks on stubs in old compressor. Make

corresponding marks on replacement compressor. Use

torch to remove stubs from old compressor and to re

install them in replacement compressor. Use copper

couplings to tie compressor back into system. Wear safety

glasses when using brazing torch. Evacuate system,

recharge, check for normal system operation.

Refrigeration System

REFRIGERATION CYCLE — In a refrigerant system,

refrigerant moves heat from one place to another. It is

useful to understand flow of refrigerant in a system.

In a straight cooling system, compressed hot gas leaves

compressor and enters condensing coil. As gas passes

through condenser coil it rejects heat and condenses into

liquid. The liquid leaves condensing unit through liquid

line and enters metering device at indoor coil. As it passes

through metering device, it becomes a gas-liquid mixture.

As it passes through indoor coil, it absorbs heat and

refrigerant is again changed to gas. The gas is returned

to compressor, where it is compressed to a hot gas, and

cycle repeats.

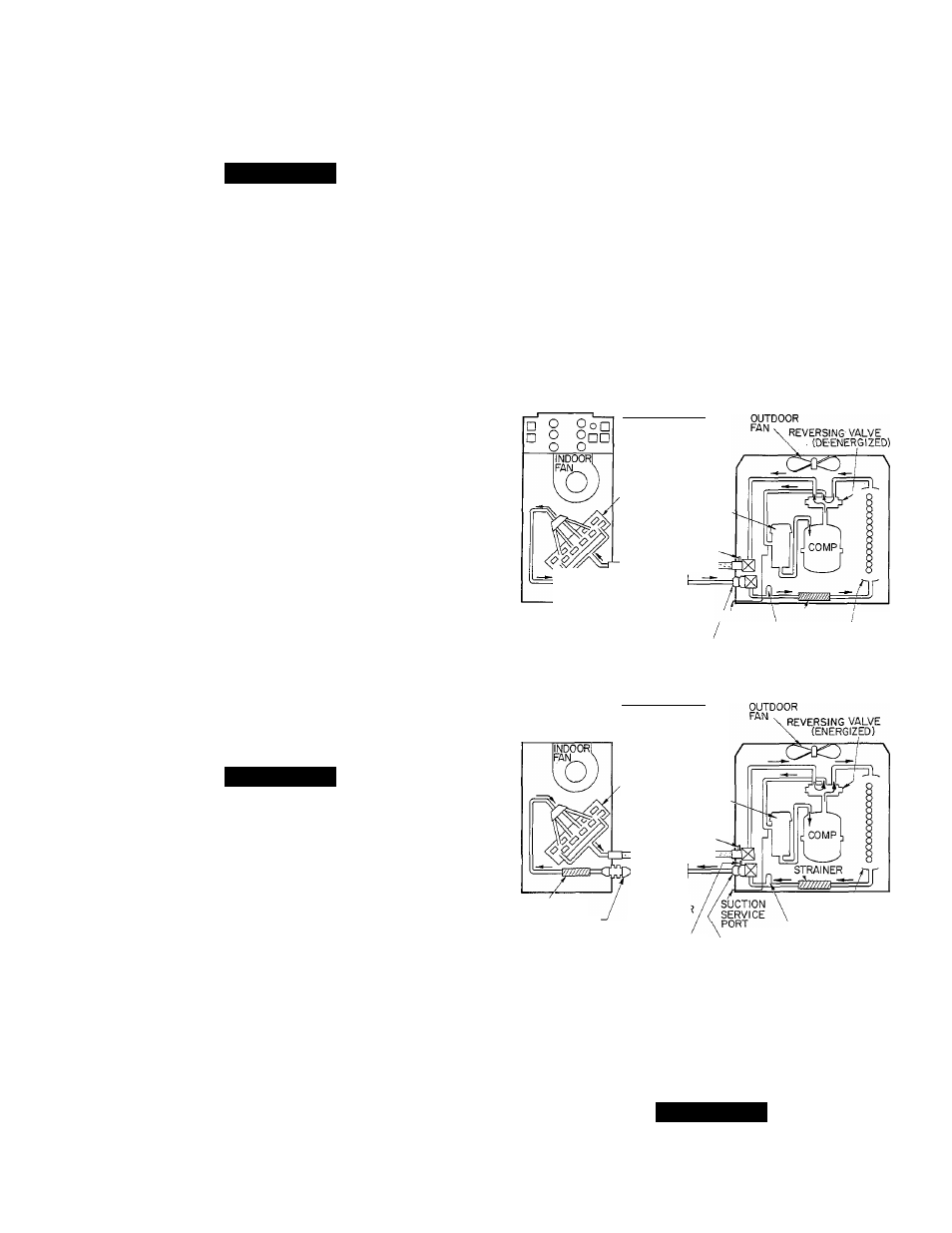

In a heat pump (see Fig. 19), the basic cycle is the same.

Reversing valve in system decides which coil, indoor or

outdoor, becomes evaporator or condenser. In heating

mode, indoor coil is condenser. It rejects heat into the

home after heat is absorbed by outdoor evaporator coil.

Thus, home is heated.

In cooling cycle, indoor coil becomes evaporator. It

absorbs heat from home and rejects it out-of-doors

through outdoor condenser coil. Thus, home is cooled.

A unique feature of the heat pump is that metering

devices are designed to meter refrigerant in one direction

of flow, and allow refrigerant to pass unhindered in other

direction. If indoor metering device is metering refrig

erant, outdoor device bypasses refrigerant and vice versa.

This allows both coils to serve a dual function.

HEATING CYCLE

INDOOR COIL

ACCUMULATOR

DISCHARGE SERVICE

PORTAT SERVICE

VALVE (HTG CYCLE)

STRAINER

ACCURATER'™

(BYPASSING)

HEAT PUMP

ACCESSORY

FILTER DRIER

(DUAL FLOW)

/SUCTION \ STRAINER

SERVICE \

OUTDOOR

PORT LIQUID LINE COIL

□ O

OoQ

□ o

Onn

o o

STRAINER

COOLING CYCLE

INDOOR COIL

ACCUMULATOR

SUCTION SERVICE

PORT AT SERVICE

VALVE (CLG CYCLE)

HEAT PUMP

ACCESSORY

FILTER DRIEF

(DUAL FLOW)

ACCU RATER

(METERING)

LIQUID LINE SERVICE PORT

AT SERVICE VALVE (CLG CYCLE)

ACCURATER

(BYPASSING)

OUTDOOR

COIL

LIQUID LINE

PRESSURE SWITCH

Fig. 19 — 38QN Heat Pump

Refrigerant Flow Diagrams

LEAK DETECTING — (See Fig. 20.) New installations

should be checked for leaks prior to complete charging.

A

CAUTION

Always wear safety glasses and gloves when handling

refrigerants.

15