A caution, Run capacitor start capacitor, A warning – Carrier 38E User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

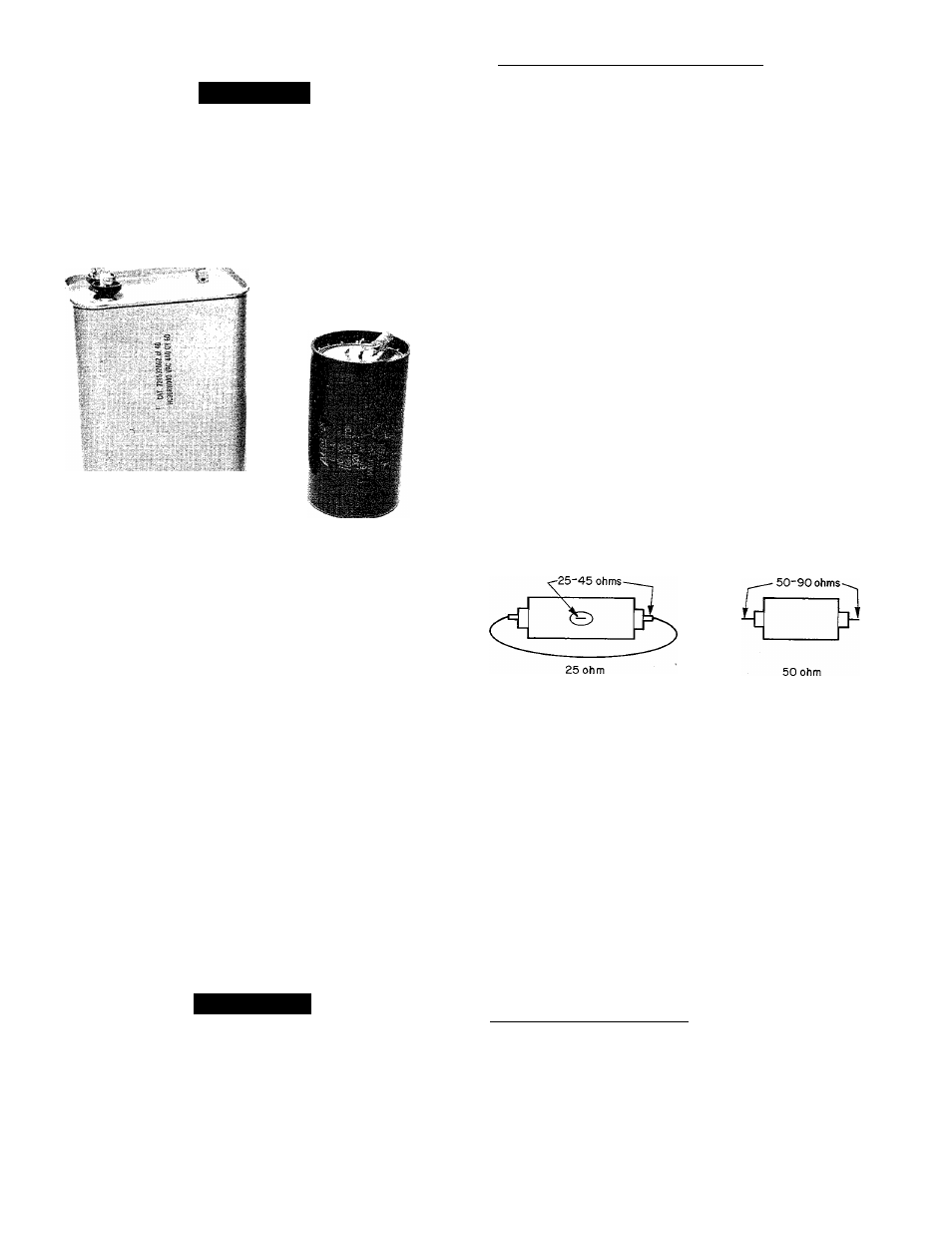

CAPACITORS — (See Fig. 5.)

A

CAUTION

Capacitors can store electrical energy when power

is off. Electrical shock can result if you touch the

capacitor terminals and discharge this stored energy.

Exercise extreme caution when working near

capacitors. With power off, discharge stored energy

by shorting across the capacitor terminals with a

15,000-ohm, 2-watt resistor, or a screwdriver blade

with insulated handle.

RUN CAPACITOR

START CAPACITOR

Fig. 5 — Capacitors

Capacitors are used as a phase shifting device to aid in

starting certain single-phase motors. Check capacitors

as follows:

1. Always check capacitors with power off. Attempting

to troubleshoot a capacitor with power on can be

dangerous. Defective capacitors may explode when

power is applied. Insulating fluid inside is combustible

and may ignite, causing burns. After power is off,

discharge capacitors as outlined above. Disconnect

capacitor from circuit. Use ohmmeter, check each

terminal to ground (use capacitor case). Discard any

capacitor that shows resistance. Place ohmmeter leads

across capacitor and place on R x 10k scale. Meter

should jump to a low resistance value and slowly climb

to higher value. Eailure of meter to do this indicates

an open capacitor. If resistance stays at zero or a low

value, capacitor is shorted.

2. Capacitance testers are available which will read value

of capacitor. If value is not within ± 10% value stated

on capacitor, it should be changed. If capacitor is

not open or shorted, its capacitance value is calcu

lated by measuring voltage across capacitor and

current it draws.

A

WARNING

Exercise extreme caution when taking readings

while power is on. Use following formula to

calculate capacitance:

^

.

, r , .

2650

X

amps

Capacitance (mfd) =

volts

3. Remove any capacitor that shows signs of bulging,

dents or leaking. Do not apply power to a defective

capacitor as it may explode.

Hard-Start Capacitors and PTC Devices — Sometimes,

under adverse conditions, a standard run capacitor in a

system is inadequate to start compressor. In these

instances, a start-assist device is used to provide an extra

starting boost to compressor motor. The first device is

called a PTC (positive temperature coefficient) or ther

mistor (see Fig. 6). It is a resistor wired in parallel with run

capacitor. As current flows through it at start-up, it heats

up. As it heats up, its resistance increases greatly, until

it effectively lowers current through it to an extremely

low value. This, in effect, removes it from the circuit.

After system shuts down, resistor cools and resistance

value returns to normal, until next time system starts.

Thermistor device is adequate for most conditions,

however, in systems where off cycle is short, device

cannot cool fully and becomes less effective as a start

device. It is an easy device to troubleshoot. Turn off all

power to system.

Check thermistor with ohmmeter as described below.

If indoor coil does not have a bleed-type expansion

device, it may be necessary to remove start thermistor

and replace with accessory start capacitor and relay.

Shut off all power to unit. Remove PTC from unit.

Wait at least 10 minutes for PTC to cool to ambient

temperature.

Measure resistance of PTC with ohmmeter. Resistance

of 25-ohm PTC is measured between center tab and

end tab with jumper across 2 end terminals.

Fig. 6 — PTC Devices

The cold resistance (Rj) of any PTC device should be

approximately 100 - 180% of device ohm rating.

50-ohm PTC = 50 - 90 ohm resistance

25-ohm PTC = 25 - 45 ohm resistance

If PTC resistance is appreciably lower or more than

200% higher than rating, device is defective.

If thermistor is good and compressor does not start,

disconnect thermistor from starting circuit. Give com

pressor a temporary capacitance boost. Run compressor

for 10 minutes, shut off, allow system pressure to equal

ize. Reconnect start thermistor. Try restarting com

pressor without boost capacitor. If after 2 attempts,

compressor does not start, remove thermistor. Add an

accessory start capacitor relay package.

Temporary Capacitance Boost — (See Fig. 7.) There are

times when a temporary capacitance boost is needed to

get compressor started. Do not under any circumstances

attach temporary boost capacitor directly across com

pressor terminals. Serious personal injury can result.

Exercise extreme caution with this procedure when high-

voltage power is on. If compressor motor does not start,

it may be due to low-line voltage, improper pressure

equalization or weak run capacitor. Check each possi

bility, attempt capacitance boosting before adding

auxiliary start capacitor and relay.