A caution – Carrier 38E User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

capacitor. Fan motor is equipped with thermal overload

device in motor windings which may open under adverse

operating conditions. Allow time for motor to cool so

device can reset. Further checking of motor can be done

with an ohmmeter. Set scale on R x 1 position, check

for continuity between 3 leads. Replace motors that show

an open circuit in any of the windings. Place one lead of

ohmmeter on each motor lead. At same time, place

other ohmmeter lead on motor case (ground). Replace

any motor that shows resistance to ground. Obviously

any motor that shows signs of arcing, burning or over

heating should be suspect and replaced.

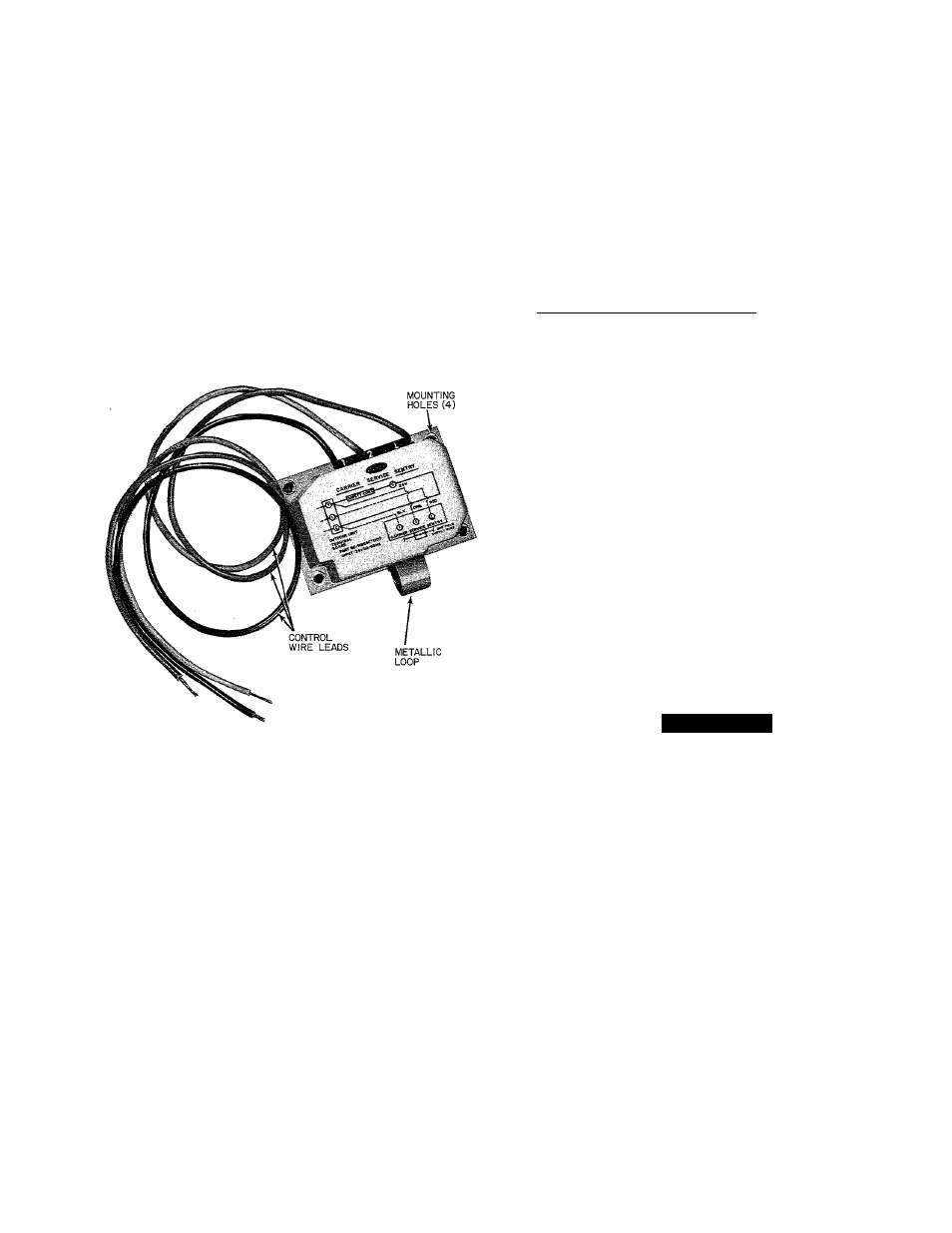

SERVICE SENTRY CONTROL BOARD — Service

Sentry control provides immediate warning when out

door heat pump requires servicing. It turns on indoor

thermostat light if compressor doesn’t operate for either

heating or cooling. This enables owner to obtain speedy

heat pump service during heating season, reducing

supplementary electric heat costs, and during cooling

.season, reducing period of heat discomfort. Fig. 14.

Fig. 14 — Service Sentry Control

Refer to Fig. 15 for wiring connections when Service

Sentry and solid-state Time Guard II accessories are used.

The Service Sentry is an accessory device. On heat

pump DL and CD option packages, a slightly different

version of Service Sentry is installed as standard equip

ment. It functions almost identically to accessory Service

Sentry except that it locks out compressor under certain

adverse operating conditions. System is manually reset by

shutting it off at thermostat subbase, then turning it back

on. If adverse condition is corrected, system restarts.

One example of an adverse condition would be if

system is located in a desert climate where high operating

temperatures may cause system to shut down on the high-

pressure switch, or on the compressor internal overload.

Service Sentry Requires 2 Inputs:

1. It must sense a 24-v input from thermostat. As thermo

stat calls for heating or cooling, it supplies 24 v to

Service Sentry device.

2. A current transformer (or induction loop) similar to

a clamp-on ammeter senses current draw in the com

pressor lead. Induction loop must sense a minimum

current draw when thermostat is calling for heating

or cooling.

NOTES:

1. On a single-phase compressor, induction loop senses

current in common leg.

2. On a 3-phase compressor, induction loop senses

current in one of the pha.ses.

Troubleshooting Service Sentry device is easy. With

thermostat calling for heating or cooling and compressor

running, indoor thermostat light should be off If on,

check for wiring errors or replace the Service Sentry.

To check for correct operation, shut off circuit breaker

or disconnect switch to outdoor unit while it is running.

Signal light on thermostat should light. If this does not

occur, check for wiring errors or replace the Service

Sentry.

A CAUTION

If Service Sentry needs replacing, shut off all power

to unit before attempting repairs.

Use Service Sentry control with single-phase Carrier

heat pumps equipped with 24-v control circuit.

Connect black, orange and red pigtails (24 v) on Service

Sentry to outdoor unit control circuit terminal board.

See Fig. 15 and wiring diagram on unit. An extra control

wire is required between L terminals on outdoor unit,

indoor unit and thermostat subbase (the L terminal is

currently being added to outdoor and indoor unit termi

nal blocks). If units do not already have L terminal, splice

control wire between L terminals on Service Sentry and

thermostat subbase. Terminal L is labeled terminal X

on some thermostat subbases (all future subbases will

read terminal L).

Connect all field line power wires to unit in usual

manner. However, route one field line power supply wire

through metallic loop on bottom of Service Sentry, then

to normal unit connection. On 015 (230-1-60) and

018 (230-1-60) units, pass supply wire through metallic

loop twice, as shown in Fig. 14 and 15. On all other units,

pass supply wire through loop only once.

OUTDOOR THERMOSTATS — (See Fig. 16.) Out

door thermostat brings on stages of electric heat as out

door temperature and heat pump output drops. Setting

at which thermostat closes is variable, depending on

design of system. It is .set at time of installation and should

not be changed without good reason. Up to 2 outdoor

thermostats may be installed. Some systems may not

have any thermostat.

Although these devices are installed in control circuit

(24 v), turn off all power to unit before attempting to

troubleshoot thermostat.

Use a standard ohmmeter to check for continuity

through thermostat. If you suspect thermostat is out of

calibration, use calibrated electronic thermometer to

determine correct outdoor temperature. Insert a screw

driver blade in adjustment slot and turn thermostat

switch until it closes. Observe this using ohmmeter across

switch. Read temperature setting when switch clo.ses. It

should be close to reading observed using electronic

thermometer. Any setting within ± 5 degrees is

acceptable.

11