A caution – Carrier 38E User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5. Remove 2 (015,018) or 4 (024,060) screws at base of

coil (located at end of large vertical wires in coil

support).

6. Lift coil vertically from basepan, place aside carefully.

NOTE: When coil is removed, use opportunity to also

remove liquid line strainer. Strainer location is

identified by label on liquid line.

7. Reverse procedure to reinstall coil.

COIL CLEANING — (See Fig. 28, 29.) For best unit

efficiency, clean outdoor coil prior to start of each heating

or cooling season. Shut off all power to unit if coil is

equipped with louvered casing. Refer to Cabinet Servic

ing for casing removal procedure. To clean coil:

A

CAUTION

Coil fin damage can result in higher operating costs

or compressor damage. Do not use ñame, high-

pressure water, steam, volatile or corrosive cleaners

on fins or tubing.

CREVICE TOOL

Clean coil using vacuum cleaner and its crevice tool.

Move crevice tool vertically, close to area being cleaned,

making sure tool touches only the dirt on the fins and

not the fins. To prevent fin damage, do not scrub fins

with tool or move tool horizontally against fins.

If oil deposits are present, spray coil with ordinary

household detergent. Wait 10 minutes, proceed to

next step.

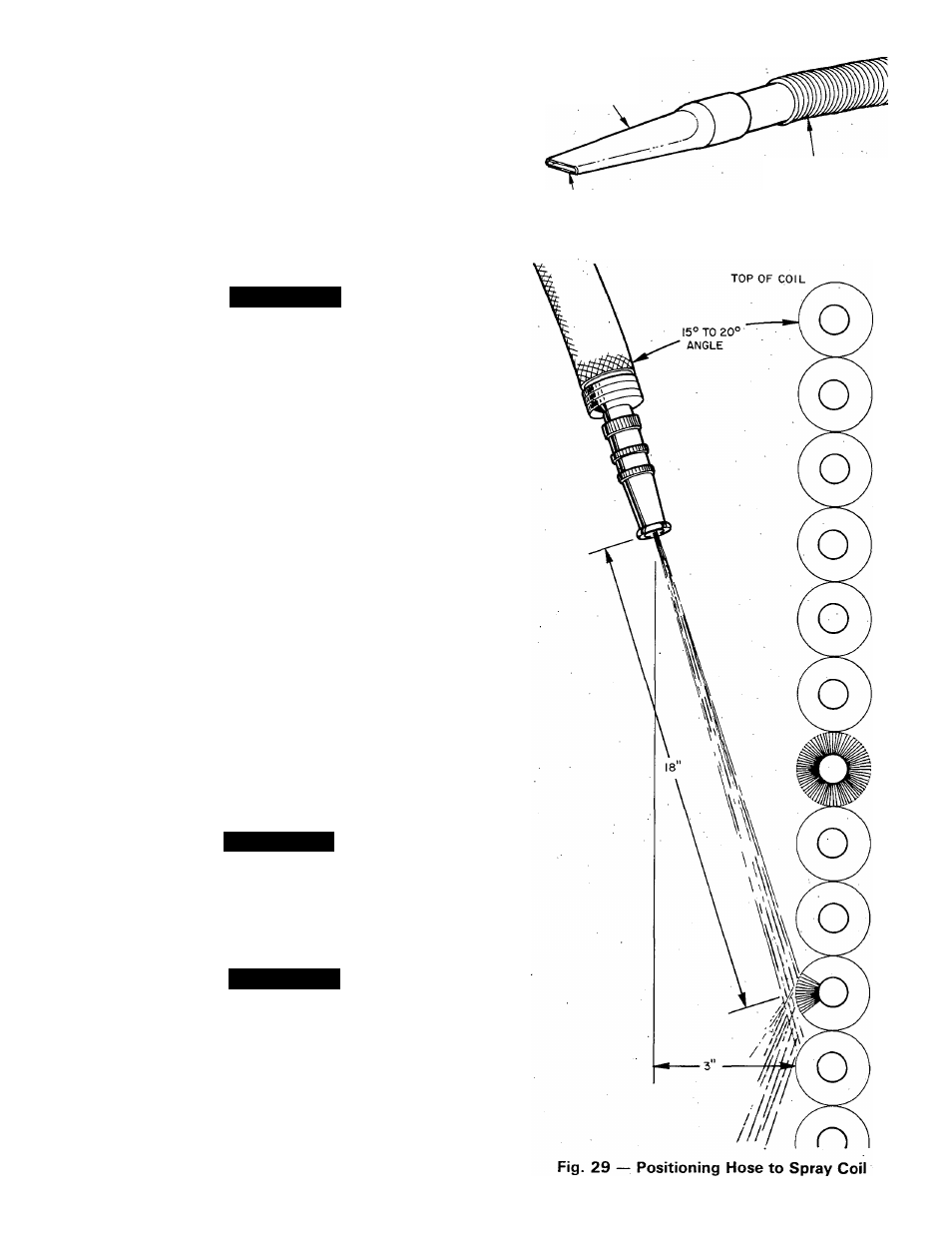

Using garden hose, spray coil vertically downward with

constant stream of water at moderate pressure. Keep

nozzle at a 15 to 20 degree angle, about 3in. (76 mm)

from coil face and 18 in. (457 mm) from tube. Spray so

debris is washed out of coil. Reinstall louvered casing

if necessary. ,

Restore power to unit.

LIQUID LINE STRAINER — Heating and cooling

models are equipped with a strainer in liquid line. It is

marked with identifying sticker. Strainer picks up harm

ful debris that may be in system. If it becomes plugged,

system does not perform properly. System pressures

become abnormal and compressor may become very hot

and cycle off on its protection device. If strainer is

plugged, it can be easily removed.

Shut off all power to unit. Bleed off all refrigerant

from system.

A

CAUTION

Wear safety glasses and gloves when handling refrig

erants. Remove fan blades and fan motor to gain

access to liquid line. Cut tubing with midget tubing

cutter near belled connection close to strainer. Peel

off identifying sticker. Unbraze stub.

A

CAUTION

Wear safety glasses when brazing. Protect any alumi-

nuih tubing in vicinity ofjoint with wet rag to prevent

overheating. After stub is removed, pull strainer

from line with needle nose pliers. Discard strainer.

Do not install another strainer. Braze liquid line

together using copper coupling. Cut liquid line

between indoor and outdoor units. Install liquid line

filter drier (bifiow drier for heat pump). Evacuate

and charge system. Add charge to compensate for

volume needed by drier. Check for normal system

operation.

VACUUM

CLEANER

HOSE

TO 2^ X I OPENINGS ARE IDEAL

Fig. 28 — Crevice Cleaning Tool

19