A caution – Carrier 38E User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

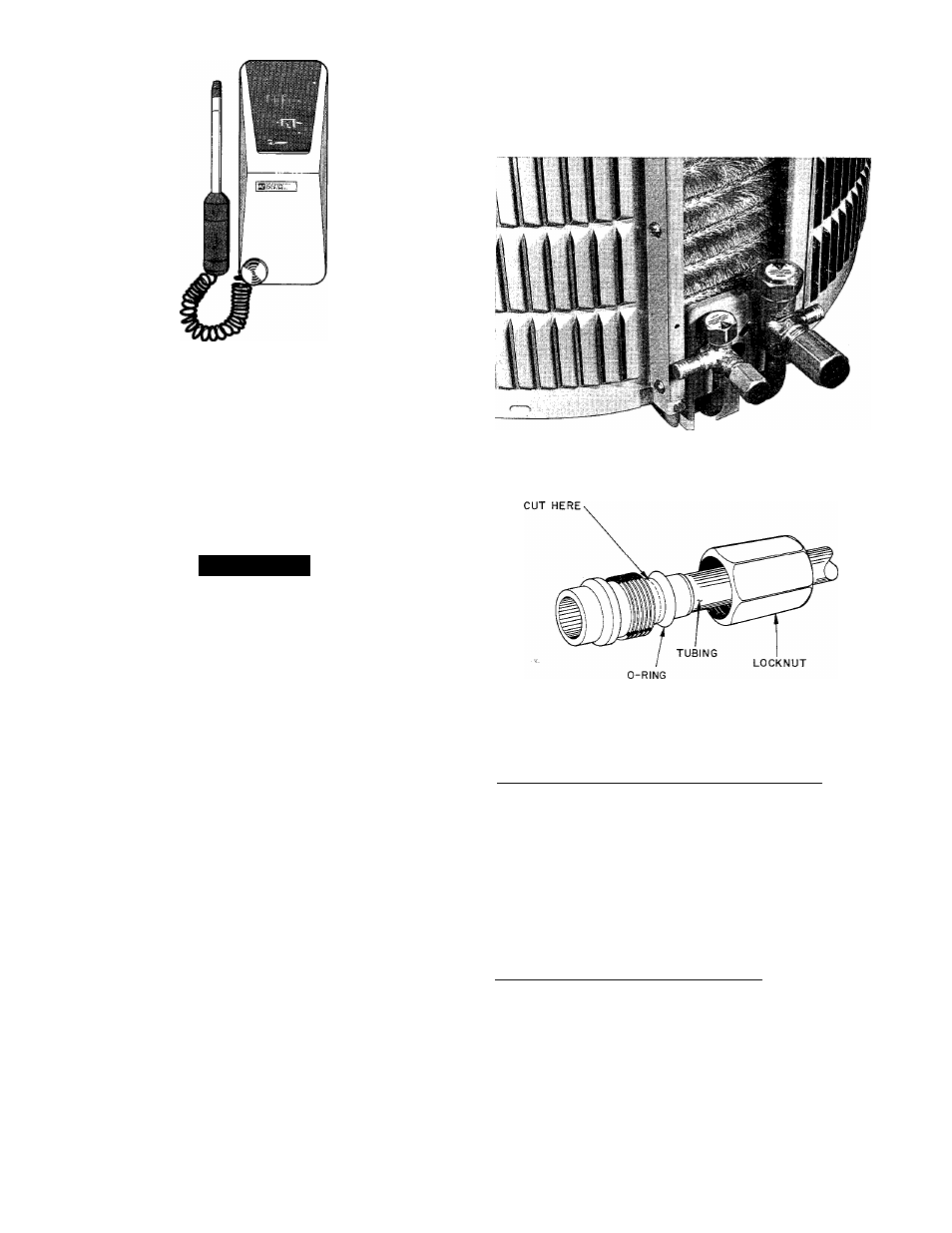

Fig. 20 — Leak Detector

If a system has lost all or most of its charge, system

must be pressurized again, up to approximately 1501b

minimum. This can be done by adding refrigerant, using

normal charging procedures. Or, it may be pressurized

with nitrogen (less expensive than refrigerant). Nitrogen

also leaks faster than R-22 and is not absorbed by refrig

eration oil. Nitrogen cannot, however, be detected by

leak detector.

A

CAUTION

Due to explosive pressures of nitrogen, it should

never be used without a pressure regulator on

the tank.

On the other hand, leaks in a system pressurized with

refrigerant can be spotted with a leak detector which

detects extremely small refrigerant leaks. This discussion

assumes that system is pressurized with either all refrig

erant or a mixture of nitrogen and refrigerant.

If system has been operating for some time, make first

check for a leak visually. Since refrigerant carries a small

quantity of oil, traces of oil at any joint or connection is

an indication the refrigerant is leaking at that point.

A simple and inexpensive method of testing for leaks is

to use soap bubbles. Any solution of water and soap

may be used.

Soap solution is applied to all joints and connections

in system. A small pinhole leak is located by tracing

bubbles in soap solution around leak.

Electronic leak detectors are now available for check

ing for leaks. These unquestionably represent the most

efficient and easiest method for checking for leaks.

There are various types of electronic leak detectors.

Generally speaking, they are all portable, most are light

weight, and consist of a box with several switches and a

probe or sniffer. Detector is turned on and probe is passed

around all fittings and connections in system. Leak is

detected by either a movement of a pointer on detector

dial, by a buzzing sound or a light.

In all instances, when a leak is found, system charge

must be hied down and leak repaired before final charging

and operation. After leak is repaired, evacuate system,

and correct refrigerant charge.

SERVICE VALVES (See Fig. 21.) Service valves pro

vide means for holding original factory charge in outdoor

unit prior to hookup to indoor coil. They also contain

gage ports for measuring system pressures, and provide

shutoff convenience for certain types of repairs.

Vapor line on all units and liquid line on condensing

units are connected to service valves by means of

Compatible Fitting. This mechanical-type fitting is also

used as a sweat fitting. Connections are made as follows:

Fig. 21 — Service Valves

COMPATIBLE FITTING

Fig. 22 — Carrier Compatible Fitting

CARRIER COMPATIBLE FITTING — (See Fig. 22.)

Mechanical Connection to Compatible Fitting — (Mate

one set of connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do not

remove.

2. Remove plug, be sure 0-ring is in groove inside

Compatible Fitting.

3. Cut tubing to correct length. Deburr and size properly,

4. Insert tube into Compatible Fitting until it bottoms.

5. Tighten nut until it bottoms on shoulder of fitting.

Keep tube bottomed in Compatible Fitting while

tightening nut.

Sweat Connection to Compatible Fitting — (Use refrig-

erant grade tubing.)

1. Remove locking nut, rubber 0-ring and Schrader

core from valve.

2. Cut tubing to correct length. Deburr and size properly.

3. Insert tube into Compatible Fitting.

NOTE: Wrap top and bottom of service valves in wet

cloth to prevent damage by heat. Solder with low-

temperature 430 F (221 C) silver alloy solder.

4. Replace Schrader core.

5. Evacuate or purge system with field-supplied

refrigerant.

16