2 maintenance procedures – Reznor X Unit Installation Manual User Manual

Page 25

Form I-X, P/N 150491 R10, Page 25

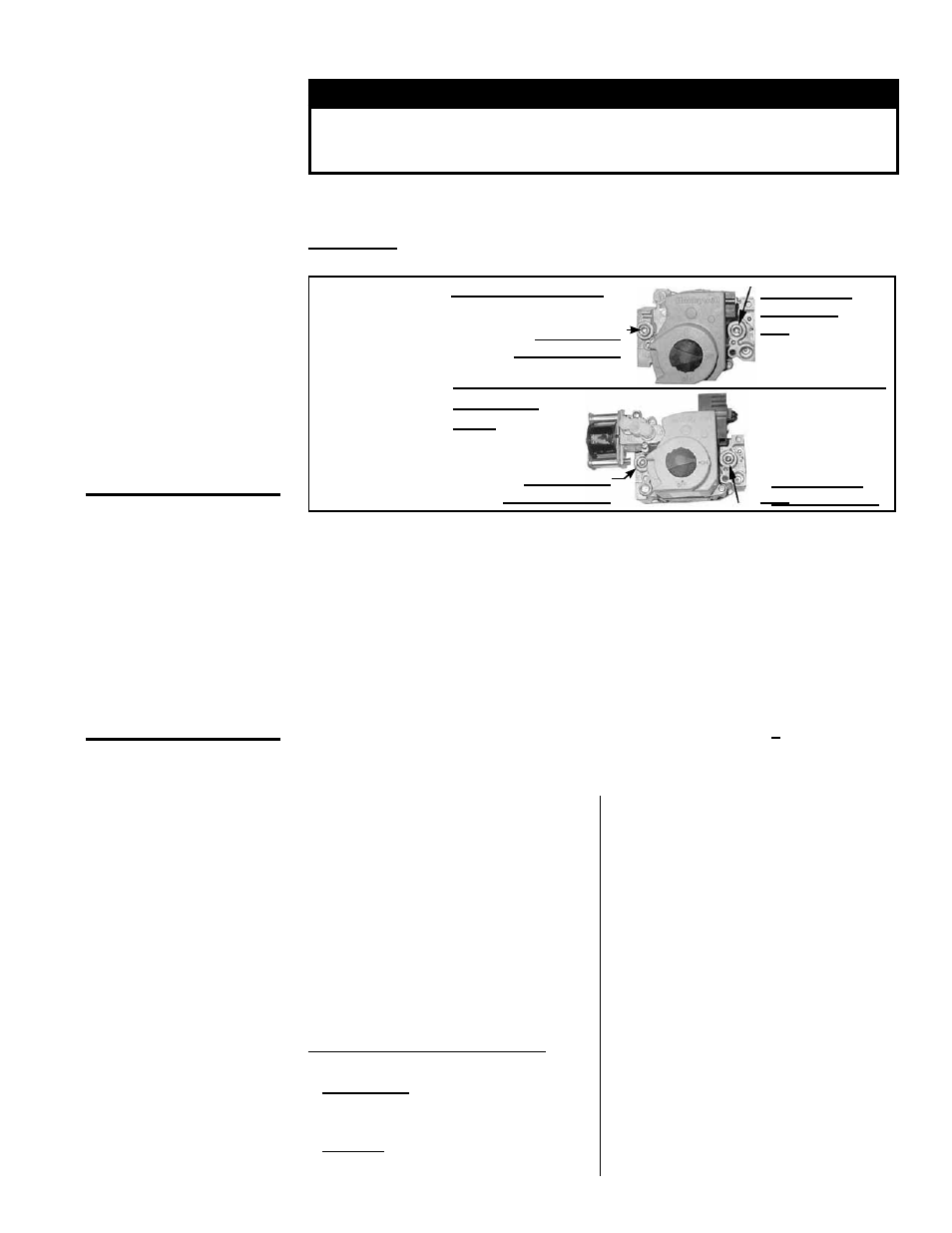

10.2.1 Operating Gas Valve

WARNING

The operating valve is the prime safety shutoff. All gas supply lines

must be free of dirt or scale before connecting to the unit to ensure

positive closure. See Hazard Levels, page 2.

Remove external dirt accumulation and check wiring connections.

The combination gas valve must be checked annually to ensure that the valve is shut-

ting off gas flow completely.

Instructions:

1) Locate the 1/8” FPT INLET pressure tap on the combination valve (FIGURE 24).

Single-Stage Valve

Two-Stage

Valve

1/8" INLET

Pressure Tap

1/8” Outlet

Pressure

Tap

1/8" INLET

Pressure Tap

1/8” Outlet

Pressure Tap

FIGURE 24 -

Gas Valve

Shutoff

Check

10.2.2 Burner Rack

Removal Instructions

2) With the manual valve turned off to prevent flow to the gas valve, connect a

manometer to the 1/8” inlet pressure tap in the valve.

NOTE: A manometer (fluid-

filled gauge) with an inches water column scale is recommended.

3) With the field-installed manual valve remaining closed, observe the manometer for

two to three minutes for an indication of gas pressure. No pressure should be indi-

cated on the manometer.

If the manometer indicates a gas pressure, the field-installed manual gas valve

must be replaced or repaired before the combination gas valve can be checked.

4) If the manometer does not indicate gas pressure, slowly open the field-installed

manual gas valve. After the manometer's indicated gas pressure has reached

equilibrium, close the manual shutoff valve. Observe the gas pressure. There

should be no loss of gas pressure on the manometer. If the manometer indicates

a loss of pressure, replace the combination gas valve before placing the heater in

operation.

CAUTION: DO NOT

bottom out the gas

valve regulator

adjusting screw.

This can result

in unregulated

manifold pressure

causing excess

overfire and heat

exchanger failure.

NOTE: Operational

pressure settings and

instructions for checking

pressure settings are in

Paragraph 6.1.

10.2 Maintenance

Procedures

1. Turn off the gas supply.

2. Turn off the electric supply.

3. Remove control access side panel.

4. Disconnect the pilot tubing &

thermocouple or flame sensor lead.

5. Mark and disconnect electric valve

leads.

6. Uncouple the union in the gas supply.

7. Remove sheetmetal screws in the top

corners of the burner rack assembly.

8. Pull "drawer-type" burner rack out of

the furnace.

To disassemble the burner rack:

1. Remove Carryover System --

Natural Gas - remove the flash

carryover system from the "manifold

end" of the burner rack.

Propane - break the lighter tube

connection at the regulator and remove

the lighter tube orifice supply tubing;

remove the retaining screws in the

drip shield and the shield; remove

the retaining screws and slide out the

lighter tube.

2. Pull main burners horizontally away

from injection opening and lift out.

3. Remove manifold bracket screws and

remove manifold.

4. Remove main burner orifices.

5. Remove screws and lift out pilot

burner.

Follow the instructions in Paragraph

10.2.3 to clean. To re-assemble and

replace, reverse the above procedures

being careful not to create any unsafe

conditions.