After startup – Reznor RDF Unit Installation Manual User Manual

Page 25

I-RDF, PN148384R5, Page 25

5. Verification of inlet gas pressure -- If, with the blower and burner operating, the

inlet main gas pressure measured in Step 3 does not correspond to the mini-

mum stated on the rating plate, check the main burner inlet gas pressure. If the

main inlet gas pressure is lower than stated on the rating plate, full burner firing

rate will not be achieved. Check main gas supply service regulator for adjustment.

Turn disconnect switch OFF.

Re-connect the "U"-tube manometer to the main burner pressure tap.

Turn pilot manual shutoff valve back ON.

Turn the disconnect switch ON; ignition sequence will occur.

Observe main burner. Light off should occur along the entire length of the burner.

After approximately one minute, record the gas pressure reading on the manome-

ter. NOTE: High outside air temperature on high fire may cause the automatic high

limit to trip. Manometer reading may only be available for a very short time.

Turn disconnect switch OFF.

Remove the manometer and replace the plug.

Remove all jumper wires and reconnect wires.

Verify that the blower, burner, and damper switches are in RUN position.

CAUTION: If blower or burner service switches are left in TEST position, they will

override control from the remote console, switch, or automatic control.

Check that all manual valves are ON.

Close the control door panel; secure latches.

Turn ON the disconnect switch. The system is now operational from the control

switch, the remote console, or other type of optional automatic control.

CAUTION: Burner will not operate if ambient air temperature is above setpoint of

outside air control (factory setting is 60°F).

Return this manual to the owner's envelope. Keep for future reference.

To check for toxic vapors coming from the surrounding outside atmosphere or

being produced by the installation (See

DANGER below), it is recommended that

the tempered makeup air entering the building be tested at its point of discharge

from the heating unit. The table below shows limits for various substances includ-

ing carbon monoxide.

Certified, portable detector tubes may be used; follow the manufacturer's instructions.

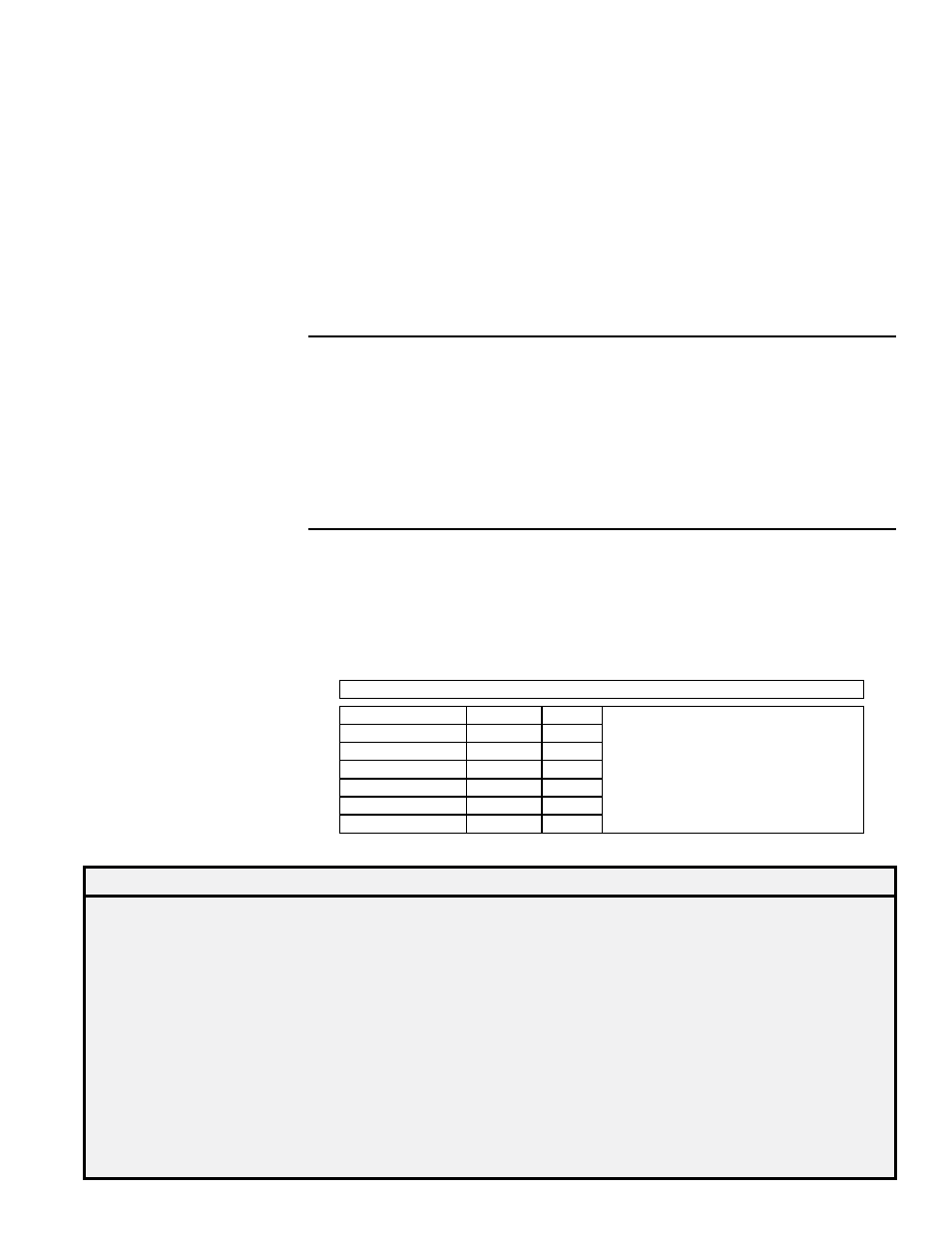

Limits Based on Eight-Hour Exposure and a Five-Day Week (Guide Only)

Startup for

Continuous

Operation

After Startup

DANGER:

The gas burner in this direct gas-fired system is designed and equipped to provide safe,

complete combustion. However, if the installation does not permit the burner to receive

the proper supply of combustion air, complete combustion may not occur. The result is

incomplete combustion which produces carbon monoxide, a poisonous gas that can cause

death.

Always comply with the combustion air requirements in the installation codes and operating

instructions. The amount of air over the burner must be within the specified range. The

burner profile plates are set at the factory to match CFM requirements. Do not adjust the

burner profile plates without contacting a factory representative. FAILURE TO PROVIDE

PROPER COMBUSTION AIR CAN RESULT IN A HEALTH HAZARD WHICH CAN CAUSE

PROPERTY DAMAGE, SERIOUS INJURY, AND/OR DEATH. Direct-fired installations should

provide for air changes as required by the applicable installation codes.

Substance

Percent

PPM

Note: At 100°F rise, the CO

2

concentra-

tion will be about 2500 ppm.

Acetaldehyde

.001

10

Carbon Dioxide

.250

2500

Carbon Monoxide .001

10

Formaldehyde

.000025

0.25

Nitrogen Dioxide

.0001

1

Sulphur Dioxide

.00005

0.5