0 check-test start, Before startup, Key to check/test/ startup procedures – Reznor RDF Unit Installation Manual User Manual

Page 22: Procedure applies to all units

I-RDF, PN148384R5, Page 22

9.0 Check-Test

Start

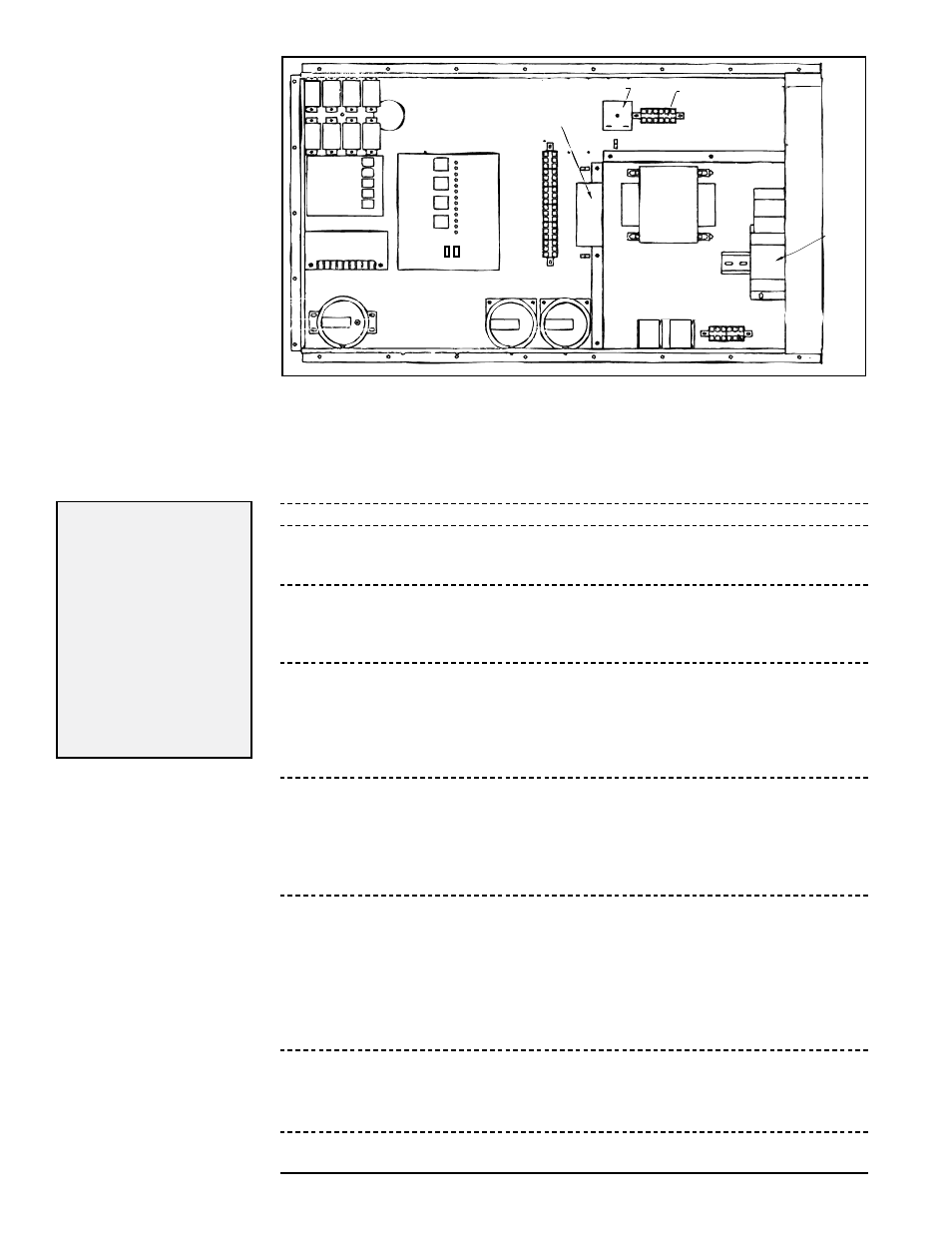

FIGURE 28 -

Control Locations

in the Electrical

Compartment

(NOTE: Locations may not

be identical, but controls

should be similar.).

Control Relays

Outside Air Cutoff

(high ambient limit control)

Time Delay Relay

24-volt Terminals

Ignition

Module

Maxitrol Amplifier

or Signal

Conditioner

Service

Switches

St

atus Light

s

Circuit

Board

24-V

olt T

erminals

Motor

Starter

Transformer

Line Voltage

Terminals

St

arter

Relay

Relay for

Optional

2-Speed

High

Low

Standard Pressure

Switches

Optional Dirty Filter

Pressure Switch

IMPORTANT NOTE: These instructions are designed for systems manufactured beginning 8/2003 equipped with hot

surface ignition and standard diagnostic lights. If the system being started was manufactured prior to 8/2003, contact

your representative or the factory service department for appropriate startup procedures.

Check/Test/Startup

Procedures (Follow

Steps in Sequence)

Before Startup

1. Check to be sure that all field-installed accessories are installed.

2. Check all field-installed wiring.

3. Check all ductwork for obstructions; open all diffusers.

4. Turn the three-position switch or optional summer/off/winter remote console

switch to OFF position. To prevent someone from turning the system on, tape the

switch leaving a note that it should be left in the OFF position.

5. If the system includes an air control with a remote potentiometer, set the posi-

tion as follows::

Option AR19 (Variable Air Volume) - Turn full "open"

Option AR22 (Return Air) - Turn full "closed"

6. Check disconnect switch --

Turn disconnect switch OFF.

Check disconnect switch to be sure that it is tightly secured against the cabinet.

If disconnect is fusible, check that fuses are installed. If fuses are not installed,

insert dual element time delay fuses sized 1.25 times the maximum total input

amps. Verify continuity of fuses.

7. Open the hinged gas/electric control compartment door --

Close all manual gas valves.

Check all wiring and wiring connections on gas controls and electrical components.

If equipped with any manually reset devices such as an optional firestat limit switch,

a high limit switch, and/or optional high gas pressure switch, reset devices. Check

setpoint on the high ambient burner cutoff air control (60°F).

8. Open the hinged door to the blower compartment --

Remove any blocking and shipping supports.

Check that the blower belts are installed and have correct tension and that pulleys

are in alignment and locked to the shaft (See Paragraph 6.4).

Inside the compartment, remove the cover from the limit switch junction box.

Reset manual limit switch.

Check wiring connections to limit switches, discharge air sensor, and motor.

Replace the junction box cover.

9. Turn ON gas supply valve and inlet manual shutoff valve on the manifold.

Leak test gas connections upstream of the electric gas valve. Be sure all connec-

tions are tight and leak tested.

WARNING: DO NOT TEST WITH OPEN FLAME.

Turn OFF manual gas valves.

10. Turn blower service switch (Electrical Compartment, See FIGURE 28) to OFF

position. If present, verify that damper test switch is in TEST position.

KEY to Check/Test/

Startup Procedures:

Procedure

applies to all

units.

Procedure only

applies to units

with the optional

component

referred to in

that procedure.