0 uncrating and preparation (cont'd), 2 preparing the furnace for installation (cont'd) – Reznor EEDU Unit Installation Manual User Manual

Page 6

Form I-EEDU, Page 6

3.0 Uncrating and

Preparation

(cont'd)

3.2 Preparing the

Furnace for

Installation

(cont'd)

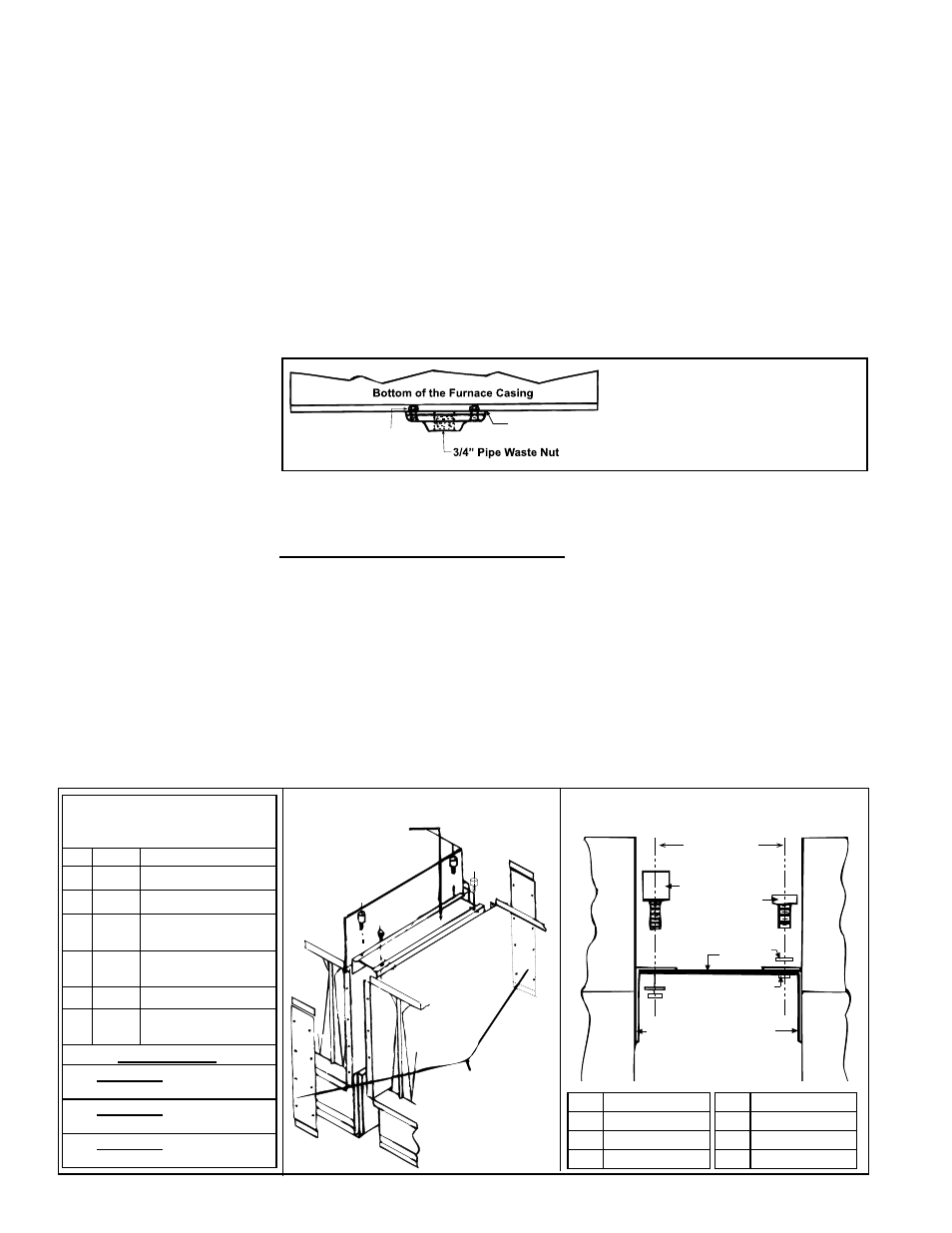

FIGURE 3 - Condensate

Drain, Option CS1

(P/N 31765)

Seal holes in bottom pan with RTV

sealant. Terminate drain outside of

building. Periodic cleaning of the

condensate collector and disposal

system is required.

3.2.3 Install Condensate

Drain, Option CS1

RTV Sealant

#10-32 x 1”Lg

Machine Screw

& Nut

Condensate can form in the heat exchanger of furnaces installed as makeup air units

or when installed downstream from a cooling coil. Under these conditions, a drain

flange, Option CS1, may be installed on the furnace bottom as shown in

FIGURE 3.

When using Option CS1, seal all corners and the four square holes in the bottom pan

edge.

NOTE: A 4-inch (102mm) minimum clearance is required under the furnace if a

90° street elbow is used.

3.2.4 Coupling Two,

Three, Four, or Five

Furnaces

Coupling of furnaces is done using optional coupling kits -- Option CR1 for two units,

Option CR2 for three units, Option CR3 for four units, or Option CR4 for five units.

Refer to the illustrations and follow the instructions.

Instructions for Coupling Furnaces (Refer to FIGURES 4A, 4B, 4C, 4D)

1. Position tie plate below hanger angle. Attach the tie plate to the first furnace

using threaded socket assemblies. Secure fasteners firmly.

2. Move the second furnace next to the first furnace. Position so that the tie plate

is below the hanger angle. Secure the tie plate to the hanger angle using the

3/8-16 bolts, the washers, and the spotweld nuts on the tie plate.

3. Position the filler plates to furnaces as shown in FIGURE 4A. Using a filler plate

as a template, drill 1/8" diameter holes. Attach filler plates using the sheetmetal

screws provided. Offset of filler plate allows alignment with unit duct flanges. See

FIGURE 4C.

4. Coupled units require access panels in the top or bottom of the outlet duct for limit

control service. See

FIGURE 4D and Paragraph 6.3.4.

Filler

Plates

Tie-Plate must

be below the

hanger angles.

See FIGURE 4B.

FIGURE 4A - Coupling Furnaces

1

2

3

5

6

7

4 (102mm)

7

Unit

1

Unit

2

FIGURE 4B - Installing Coupling Kit

Tie Plate

Coupling Kit Components,

Option CR1 (P/N 57963), for

Two Furnaces

Qty

P/N

Description

2

57964 Filler Plate

1

57965 Tie Plate

2

9557 Threaded Socket

Assembly

2

5095 3/8-16 x 1-1/4" lg Hex

Head Bolts

2

5197 Split Ring Lock Washer

20

11813 #10 x 1/2" lg

Sheetmetal Screws

Additional Kits:

3 Furnaces - Option CR2

(P/N 82654)

4 Furnaces - Option CR3

(P/N 82655)

5 Furnaces - Option CR4

(P/N 82656)

Item Description

1 Socket Assembly

2 Bolt

3 Lockwasher

Item Description

5 Spotweld Nut

6 Tie Plate

7 Hanger Angles

Tie plate (6)

MUST

be under

both hanger

angles (7).

b) With the limit control on the heat exchanger side of the bracket, slide the limit

control/bracket assembly into the hole. Attach the bracket with two sheetmetal

screws.

c) Cover all of the original factory-made limit control holes with a field-supplied

sheetmetal plate. Do not leave any open holes in the side panel or the heat

exchanger bottom.

4. The furnace is now ready for installation with the airflow from front to rear (gas valve

side).

3.2.2 Instructions for Reversing Airflow (cont'd)