Reznor EEDU Unit Installation Manual User Manual

Page 5

Form I-EEDU, P/N 150492 R6, Page 5

Heating -- Gas

Control Option

Option AG7 - Amplifier, P/N 260863; Thermostat, P/N 48033

Makeup Air --

Control Options

(All of the makeup

air options also

require a shipped-

separate fan control,

Option CQ1 (P/N

57960), which

should be at the job

site.)

Option AG3 - Control Switch, P/N 29054; Gasket, P/N 7726; Gasket Retainer Plate, P/N 7727

Option AG8 - Temperature Sensor and Mixing Tube, P/N 48041; Amplifier, P/N 260864; Control

Switch,

P/N 29054

Option AG9 - Remote Temperature Selector, P/N 48042; Temperature Sensor and Mixing Tube,

P/N 48041; Amplifier, P/N 260863; Control Switch, P/N 29054

Option AG15 - Remote Temperature Selector, P/N 115848; Stage Adder Module, P/N 115849;

Control Switch,

P/N 29054; Transformer 115 to 24V, P/N 103055 or 208/230 to 24V, P/N 103497;

and 1/2" locknut,

P/N 16222 (for transformer); Discharge Sensor Holder, P/N 115850; Discharge

Air Sensor Holder Bracket,

P/N 213612

Option AG21 - Signal Conditioner, P/N 134170; Conditioner Relay, P/N 14747; Transformer 115

to 24V,

P/N 103055; Fuse Box, P/N 12697; Fuse Box Cover, P/N 12698;

(3) Hole Plugs,

P/N 16451; Transformer Locknut, P/N 16222

Other shipped-separate options could include a gas shutoff valve, a vent cap, a con-

densate drain fitting, a thermostat, a hanger kit, a coupling kit, and/or a fan control.

Option Parts -- Some gas

control options will have

parts either shipped loose

with the heater or shipped

separately. If your unit is

equipped with any of the

gas control options in the

table, be sure these parts

are available at the job site.

3.2.1 Converting

Furnace for Higher CFM

Application

This furnace was factory assembled with the air throughput range listed on the rating

plate. If the application requires a higher CFM than listed on the rating plate, refer to

the requirements and instructions in the

APPENDIX, page 30.

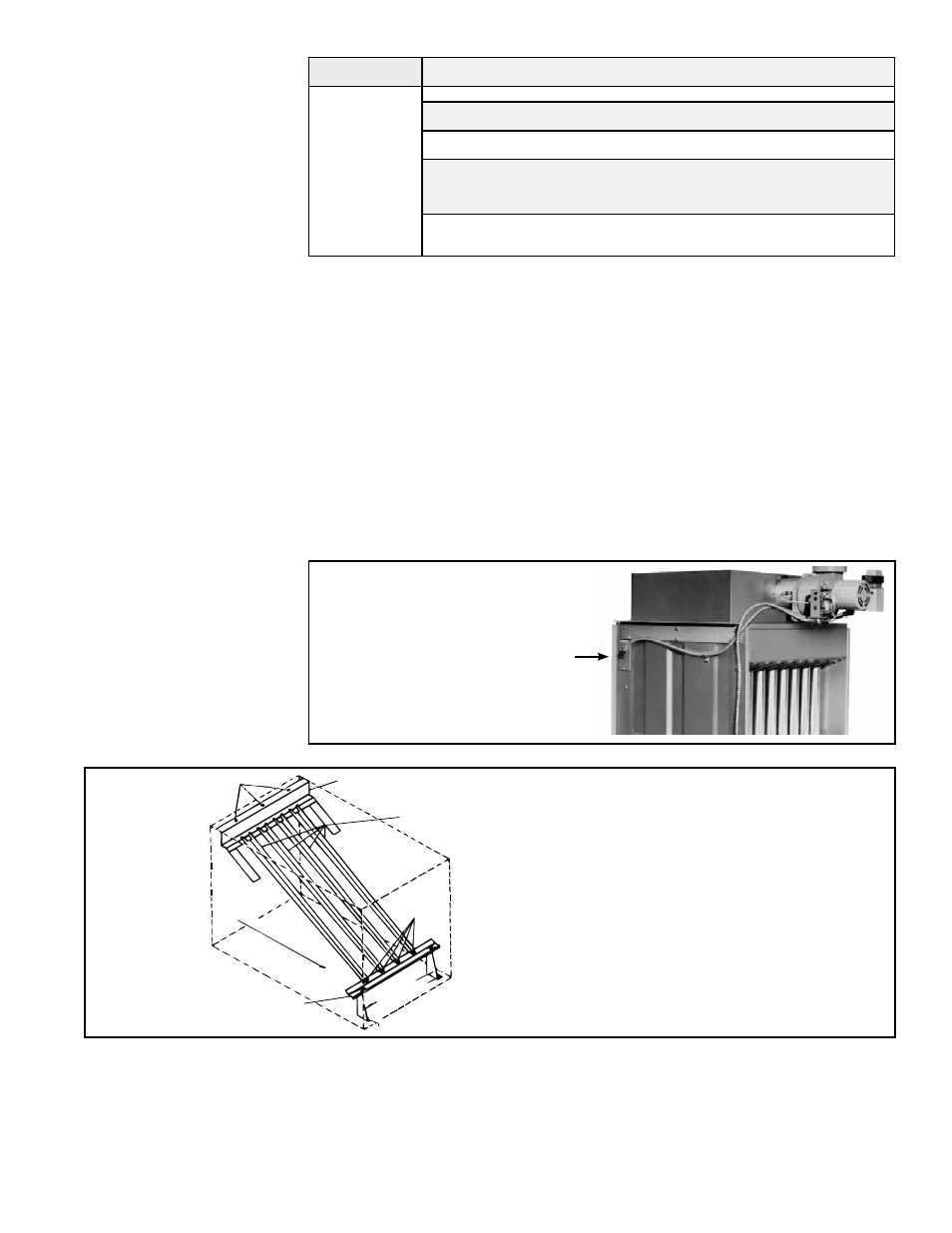

1. Refer to FIGURE 2A. Remove the screws attaching the limit control bracket to the

side of the furnace. Carefully pull the bracket/control assembly through the hole. (Do

not disconnect wires.)

FIGURE 2A - Limit

Control Location -

When reversing airflow,

the limit control must

be re-located. The limit

control MUST be on the

discharge end of the

heat exchanger

Location of the factory-

installed Limit Control

Bracket on a Furnace with

Standard Airflow Direction

Duct furnaces are equipped with directional air baffles between the heat exchanger

tubes. Facing the control compartment of the furnace, the standard direction of airflow

is from the rear of the furnace (gas valve location) toward the front of the furnace. If the

installation site requires airflow from the front to the rear, the unit may be field adapted

by re-locating the limit control and reversing the position of the directional air baffles.

Instructions for Reversing Airflow

2. Refer to FIGURE 2B and follow Steps a)-d) to reverse the direction of the baffles.

Top Baffle

Support

Screws B

Bottom

Baffle Support

Bracket

s

Air Discharge

Direction of

Airflow

Screw C

Right

Lef

t

Screws A

Screw C

Airflow

Baffles

a) Remove Screws "A". Individually lift each baffle slightly

and slide forward. Remove all baffles completely from the

heat exchanger.

b) Remove Screws "B" and the top baffle support assembly.

Re-position the assembly on the opposite end of the heat

exchanger and attach.

c) Remove Screws "C" and the assembled bottom baffle

support and brackets. Plug the holes in the heat

exchanger bottom by re-inserting the screws in the holes.

Position the assembly on the opposite end of the heat

exchanger and attach using field-supplied sheetmetal

screws.

d) Re-install all of the individual baffles by reversing

procedure in Step a) above.

FIGURE 2B -

Model EEDU

has a top

and bottom

support

assembly

and

individual

baffles.

3. Relocate the limit control.

a) At the discharge end on the same side of the heat exchanger, measure down

4-1/2" (114mm) and across 1-11/16" (43mm). Using that point as the center, punch

a 2-1/4" (57mm) diameter hole in the side panel.

NOTE: It may be necessary to move cable connections. Re-insert screws to plug all

holes in the side panel. After the limit control is installed, the cable connections may be

re-attached using field-supplied sheetmetal screws.

3.2.2 Instructions for

Reversing Airflow by

Changing Directional

Air Baffles in the Heat

Exchanger

NOTE: If the unit has optional outer

side panels, locate the limit control and

remove the outer panel on that side of

the furnace.