4 gas controls, 0 controls (cont'd), 3 fan control (cont'd) – Reznor EEDU Unit Installation Manual User Manual

Page 22: Warning

Form I-EEDU, Page 22

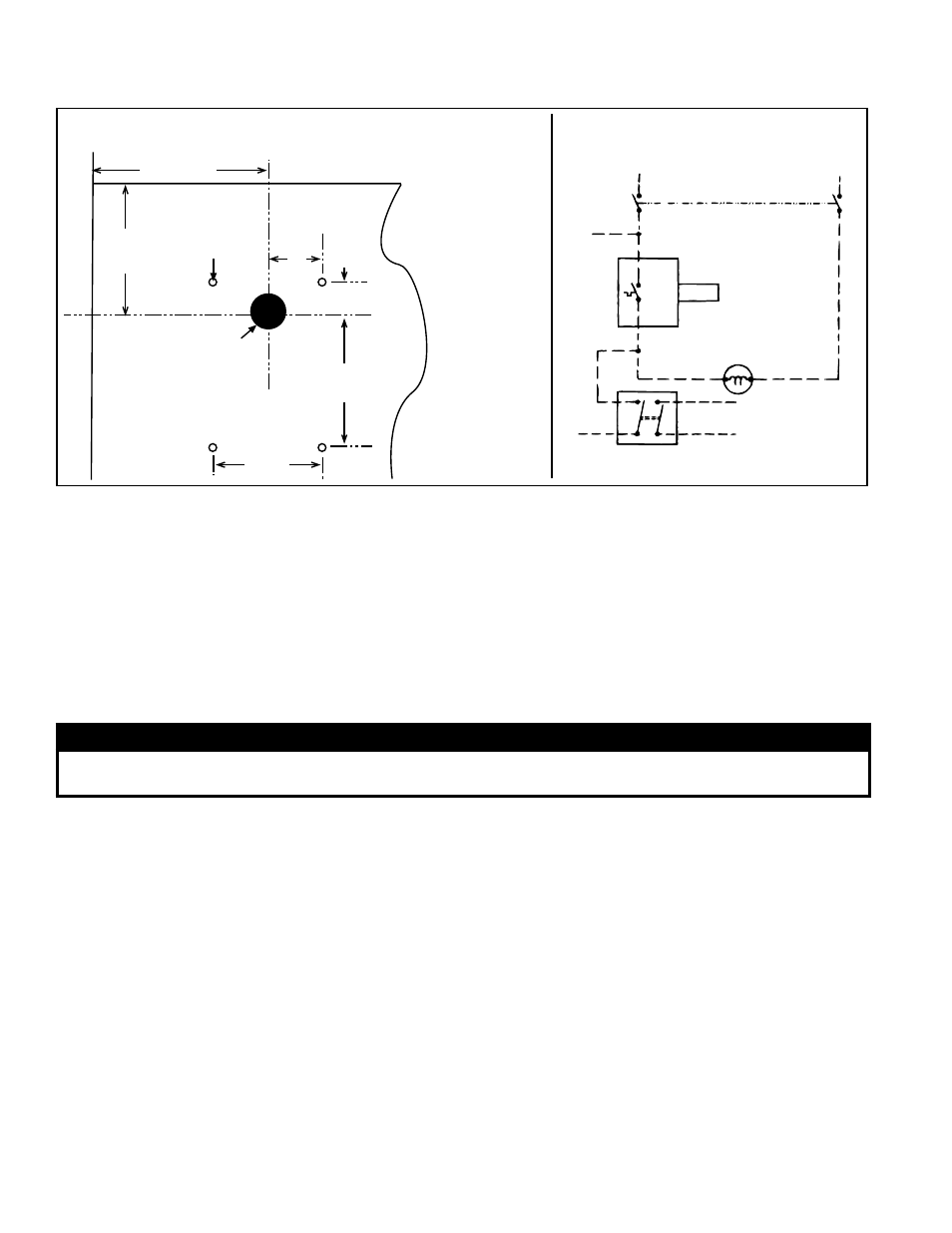

4 (102mm)

3

(76mm)

2-3/8

(60mm)

3

(76mm)

3/4 (19mm)

1-3/16 (30mm)

Drill one 13/16

(20.6mm) diameter

hole for the element.

Drill four 1/8

(3mm) diameter

holesfor screws.

(Discharge

Duct)

(Heater)

HOT

COM

120V or 230V

Power Supply

Line Switch

Fan

Line

Fan

Load

Blower Motor or Starter Coil

DP-ST Control Switch (Used with

Options AG3, AG8, AG9, and AG15)

To Gas Control

Circuit

Rating

120V - 14 - F.L.

120V - 84 - L.R.

230V - 7 - F.L.

230V - 42 - L.R.

FIGURE 20C - Typical Fan Control

Wiring (W.D. 145977)

Install the gasket

supplied in the

option kit between

the fan control and

the duct.

FIGURE 20B - Location of Fan Control Mounting Holes

8.4 Gas Controls

8.4.1 Gas Valve

All furnaces are equipped with a 24-volt combination valve which includes the auto-

matic electric on-off valve controlled by the room thermostat, the pressure regulator,

and the manual shutoff valve. The standard gas valve allows for single-stage control

from a single-stage, 24-volt thermostat.

WARNING

The operating valve is the prime safety shutoff. All gas supply lines must be free of dirt or scale

before connecting the unit to ensure positive closure. See Hazard Levels, page 2.

8.4.2 Optional Two-

Stage Operation -

Heating Only

NOTE: Not available on

Size 75 using propane.

8.4.3 Optional Two-

Stage Operation -

Makeup Air

The standard combination control valve is replaced with a two-stage combination gas

control valve providing for low fire or high fire operation controlled by a two-stage

thermostat. First stage (low fire) is factory set (not field adjustable). Both high and low

stages are controlled by a Servo regulator, maintaining constant gas input under wide

variations in gas supply pressure. See instructions in the envelope with the unit for

specific gas valve specifications, wiring, and operating instructions.

3. To be sure that the fan can continue to operate, the power supply to the heater

MUST NOT be interrupted except when servicing the heater.

4. If the customer wants the heater off at night, the gas valve circuit SHOULD BE

OPENED by a single pole switch wired in series with the thermostat. Some ther-

mostats are provided with this feature. Multiple units controlled from a single ther-

mostat are shut off in the same manner. For proper operation, be sure fan control

wiring is observed. See

FIGURES 20 A, B, & C for installation and wiring.

Two-stage makeup air units are equipped with a two-stage gas valve, but instead of

control from a two-stage room thermostat, the outlet air temperature is monitored and

controlled by a two-stage ductstat. When the discharge air temperature drops to the

setpoint, low fire is energized. If low fire cannot satisfy the ductstat setting, high fire is

energized.

Makeup air applications are usually adjusted to discharge an outlet air temperature

between 65°F and 75°F. In all applications, the allowable temperature rise of the fur-

nace in the installation dictates the limits of the ductstat temperature setting.

Depending on the option selection, the factory-installed sensor is either field-con-

nected by capillary tubing to the unit-mounted ductstat (Option AG3,

FIGURES 21),

or electrically connected to a remote electronic remote temperature selector (Option

AG15,

FIGURE 22).

NOTES: Makeup air option

requires field installed fan

control, see Paragraph 8.3.

This option is not available

on Size 75 using propane

gas.

8.0 Controls (cont'd)

8.3 Fan Control (cont'd)