0 mechanical (cont'd), 2 venting (cont'd) – Reznor EEDU Unit Installation Manual User Manual

Page 12

Form I-EEDU, Page 12

6.0 Mechanical

(cont'd)

NOTE 1: If the system

contains all vertical pipe

or a combination of

vertical and horizontal

vent pipe, the Maximum

Permissible Vent Length

shown in TABLES 1

and 2 may be increased

one foot for each foot

of vertical pipe, up to a

maximum increase of 10

feet for Model Sizes 75 -

125 and up to 20 feet for

Model Sizes 140 - 400.

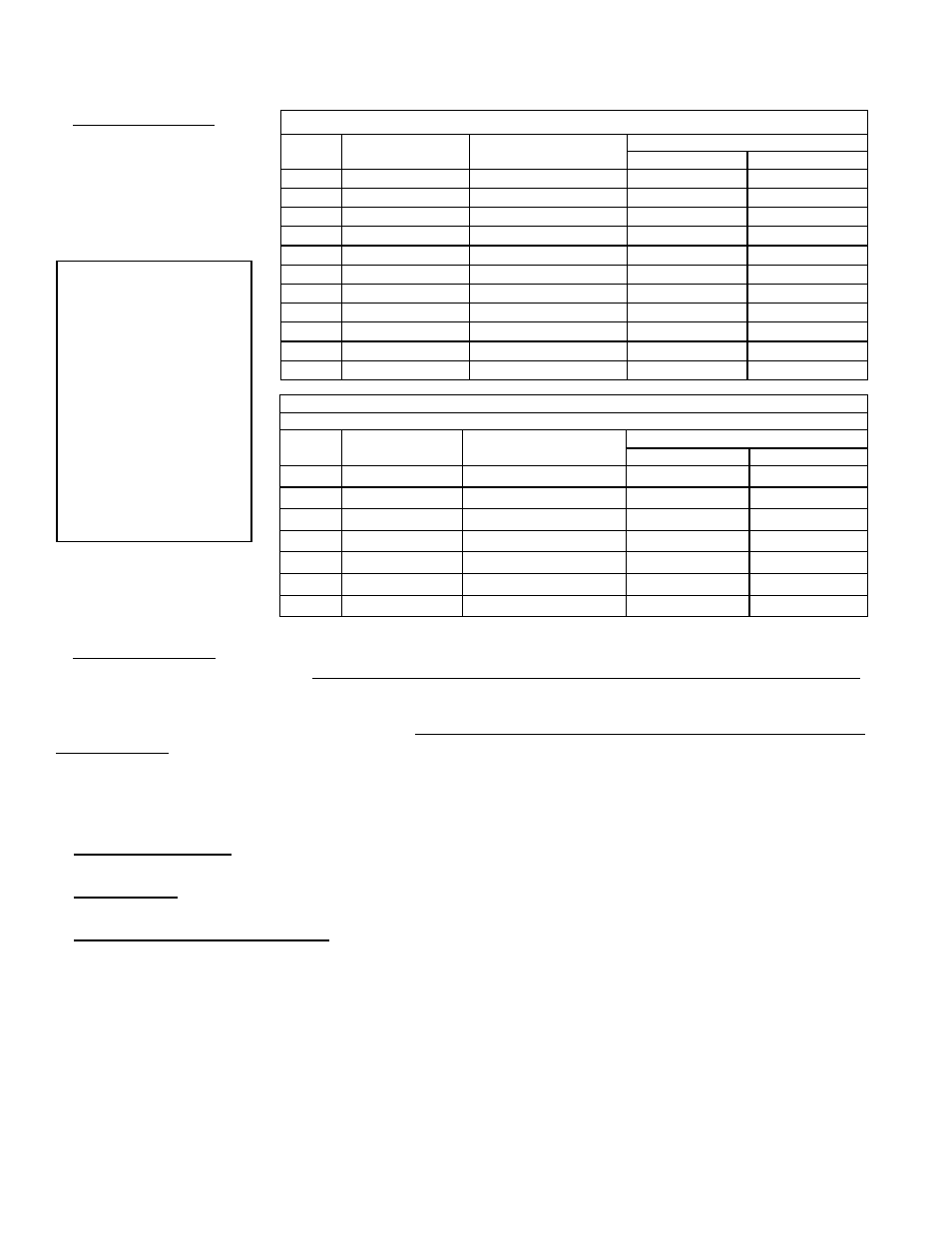

TABLE 1: Maximum Permissible Vent Lengths with Standard Vent Pipe Diameters

Size

Vent Pipe Diameter

(inches)

Maximum Vent Length

(see NOTE 1 left)

Equivalent Straight Length* - ft (M)

90°Elbow

45°Elbow

75

4

40 ft (12.2 M)

6 (1.8)

3 (.9)

100

4

50 ft (15.2 M)

7 (2.1)

3.5 (1.1)

125

4

50 ft (15.2 M)

7 (2.1)

3.5 (1.1)

140

4

50 ft (15.2 M)

7 (2.1)

3.5 (1.1)

170

4

50 ft (15.2 M)

7 (2.1)

3.5 (1.1)

200

4

50 ft (15.2 M)

7 (2.1)

3.5 (1.1)

225

5

50 ft (15.2 M)

9 (2.7)

4.5 (1.4)

250

5

50 ft (15.2 M)

9 (2.7)

4.5 (1.4)

300

6

50 ft (15.2 M)

11 (3.4)

5.5 (1.7)

350

6

50 ft (15.2 M)

11 (3.4)

5.5 (1.7)

400

6

50 ft (15.2 M)

11 (3.4)

5.5 (1.7)

TABLE 2: Optional Maximum Permissible Vent Lengths

(Requires an increase in vent pipe diameter.)

Size

Vent Pipe

Diameter (inches)

Maximum Vent Length

(see NOTE 1 left)

Equivalent Straight Length* - ft (M)

90°Elbow

45°Elbow

170

5

60 ft (18.3 M)

9 (2.7)

4.5 (1.4)

200

5

70 ft (21.3 M)

9 (2.7)

4.5 (1.4)

225

6

70 ft (21.3 M)

11 (3.4)

5.5 (1.7)

250

6

70 ft (21.3 M)

12 (3.7)

6 (1.8)

300

7

70 ft (21.3 M)

13 (4.0)

6.5 (2.0)

350

7

80 ft (24.3 M)

13 (4.0)

6.5 (2.0)

400

7

90 ft (27.4 M)

14 (4.3)

7 (2.1)

* Tables 1&2 - Reduce the

maximum vent length by the

amount indicated for each

elbow used.

4. Vent System Joints - Vent system joints depend on the installation and the type of pipe being used.

If installed as a Category III heater (required if more than half of the equivalent length of the vent system is horizontal)

and single-wall vent pipe is being used, use at least two non-corrosive screws per vent pipe joint and seal all joints

to prevent leakage of flue gases into the building. For sealing joints, tape suitable for 550°F is recommended (required

in California).

If installed as a Category III heater (required if more than half of the equivalent length of the vent sys-

tem is horizontal)

and vent pipe specifically approved for Category III vent systems is being used, follow the pipe

manufacturer's instructions for proper sealing.

If installed with a Category I vent system (allowed only if at least half of the equivalent length of the vent sys-

tem is vertical), use at least two non-corrosive screws per vent pipe joint on single-wall pipe or follow the pipe manu-

facturer's instructions for joining double-wall pipe. Refer to

FIGURE 10A when attaching vent cap to double-wall pipe.

5. Vent System Support - Support lateral runs every six feet (1.8M), using a non-combustible material such as strap

steel or chain. Do not rely on the heater for support of either horizontal or vertical vent pipe.

6. Condensation - Single-wall vent pipe exposed to cold air or run through unheated areas must be insulated. Where

extreme conditions are anticipated, install a means of condensate disposal.

7. Vent Terminal (Pipe and Vent Cap) - Terminate the vent system with a Reznor Option CC1 vent cap that in most

cases is the same size as the vent run. Heaters to be installed in the United States that are ordered with an optional

vent cap and all heaters ordered for Canada have a vent cap packaged with the heater. If the "standard" size vent pipe

listed in Vent Length Table 1 is used; install the vent cap provided.

If a vent cap is not included or if a non-standard size (Vent Length Table 2) of vent pipe is used, provide a Reznor

Option CC1 vent cap in the appropriate size.

NOTE: If the vent run is 7" vent pipe, install an 8" vent cap using a tapered

enlarger.

See the illustrations in

FIGURES 11A and 11B for requirements of either vertical or horizontal vent termination. The vent

terminal section may be either single-wall or double-wall (Type B) vent pipe.

If double-wall pipe is used in the vent terminal, follow the instructions in

FIGURE 10A to attach the vent cap and in FIG-

URE 10B to connect the double-wall pipe to the single-wall or Category III vent pipe run.

6.2 Venting (cont'd)

Specific Venting Requirements (cont'd)

3. Vent Length Tables