3 constructing bypass duct, Figure 13 - bypass duct – Reznor EEDU Unit Installation Manual User Manual

Page 15

Form I-EEDU, P/N 150492 R6, Page 15

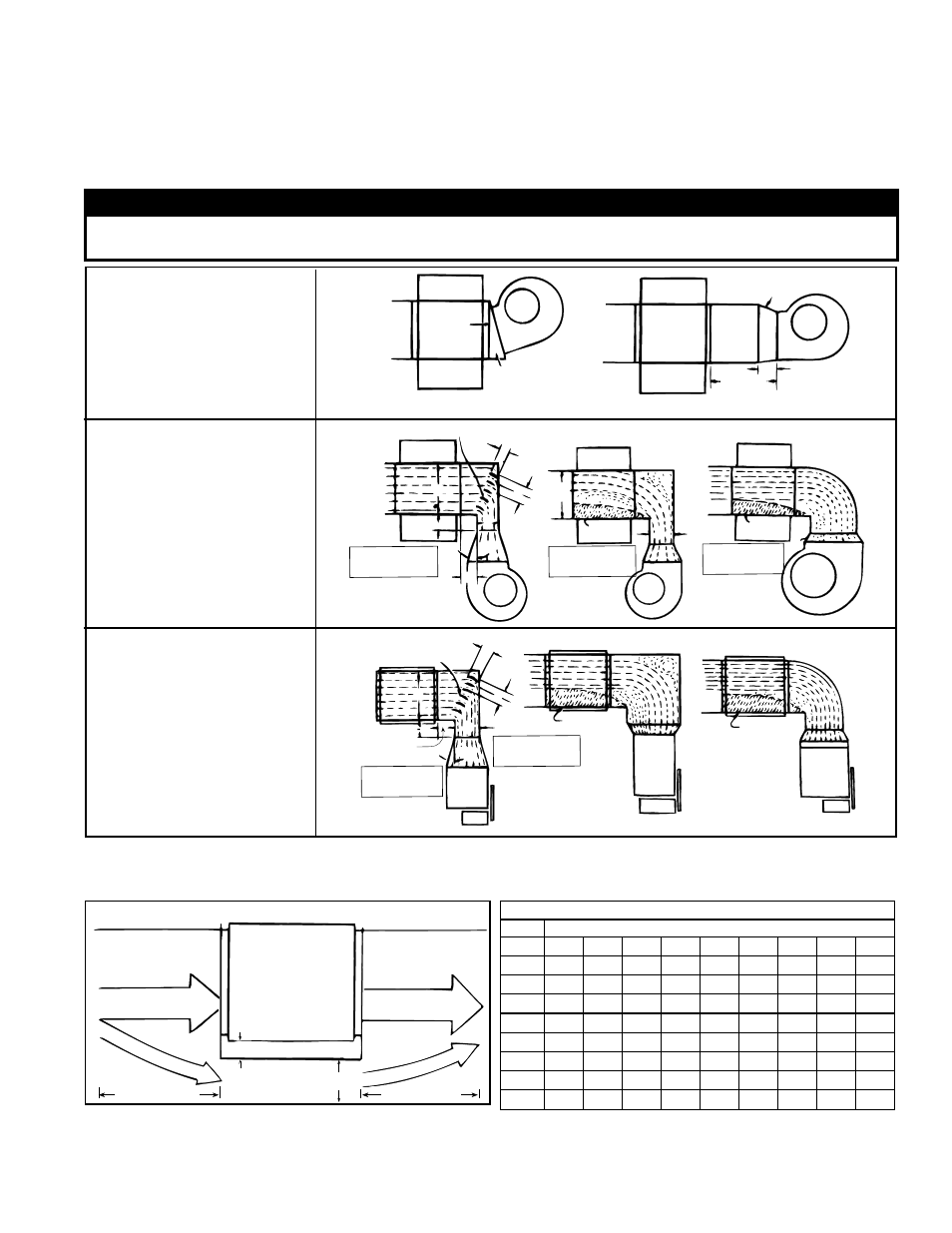

6.3.3 Constructing

Bypass Duct

Top View

of Furnace

Control Side

Bypass Duct A

2 (51mm) minimum

18 (457mm)

18 (457mm)

FIGURE 13 - Bypass Duct

Bypass CFM

"A"

Pressure Drop through the Furnace

Width 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

3"

490

530

610

700

780

830

900

960 1010

4"

630

750

870

980 1090 1160 1250 1310 1400

5"

850 1010 1190 1300 1410 1520 1640 1730 1810

6"

1050 1290 1480 1650 1800 1940 2090 2200 2320

7"

1250 1510 1760 1960 2180 2320 2500 2650 2800

8"

1490 1810 2100 2350 2560 2760 2940 3110 3290

9"

1700 2100 2400 2700 2970 3200 3400 3600 3800

10"

1920 2350 2760 3090 3650 4020 4300 4550 4800

When the CFM of air throughput is greater than desirable or permissible for the unit,

a bypass duct may be constructed. Follow these instructions to determine the correct

size of the bypass duct.

Directions for Sizing

Bypass Duct

6.3.2 Duct Furnace

Blower Connections

Proper arrangements of blower and duct furnace with respect to angle of approach

of the duct connection and the arrangement of the discharge opening of the blower

are shown. Blowers should be bottom horizontal discharge when coupled to the duct

furnace. When a top horizontal discharge blower is connected to the duct furnace, be

sure that sufficient length of duct is provided to permit even flow of air at the end of the

duct. Or, baffles may be inserted between the blower and the heater to assure an even

flow of air across the heat exchanger. See illustrations in

FIGURE 12 A, B, and C.

FIGURE 12A - Straight

through Air Blower

Connection

Direct

Coupling

Slanted Transition

Suggested blower connections for straight through airflow.

Use either method for good air coverage and efficient operation.

15°

6 (152mm)

Remote

24

(610mm)

minimum

Turning Vanes

3(76mm)

3(76mm)

3(76mm)

6 (152mm)

6

(152mm)

X

15°

Y

No air

X

No air

Z

NOTE: X should

never be less than

1/2 Y

NOTE: X should

never be less

than 1/2 Y

NOTE: Angle Z

should never be

more than 15°

Turning Vanes

3(76mm)

3(76mm)

3(76mm)

6 (152mm)

6 (152mm)

Z

NOTE: Angle Z

should never be

more than 15°

X

15°

No air

GOOD

GOOD

POOR

POOR

POOR

No air

POOR

Y

Y

NOTE: X should

never be less

than 1/2 Y

WARNING

The furnace must be installed on the positive pressure side of the air-circulating blower. See Hazard

Levels, page 2.

FIGURE 12B - Blower

Connection With

Elbows Up or Down

FIGURE 12C - Blower

Connection with Elbows

Right or Left

1) From the tables in Paragraph 6.3.1, find the pressure drop (P.D.) and the allowable

CFM for the furnace that is being installed.

Example: Standard Size 170 @ 70°F temperature rise; P.D. .33; CFM 1790