0 controls, 1 combustion air proving switch, 2 limit switch – Reznor EEDU Unit Installation Manual User Manual

Page 21: 3 fan control (optional, field installed)

Form I-EEDU, P/N 150492 R6, Page 21

8.1 Combustion Air

Proving Switch

8.0 Controls

Pressure

Switch

Table

The combustion air proving switch is a pressure sensitive switch that monitors air pres-

sure to ensure that proper combustion airflow is available. The switch is a single pole

- normally open - device which closes when a decreasing pressure is sensed in the

outlet duct of the flue gas collection box.

On startup when the heater is cold, the sensing pressure is at the most negative level,

and as the heater and flue system warm up, the sensing pressure becomes less nega-

tive. After the system has reached equilibrium (about 20 minutes), the sensing pres-

sure levels off.

If a restriction or excessive flue length or turns cause the sensing pressure to become

less than the switch setpoint, the pressure switch will function to shut off the main burn-

ers. The main burners will remain off until the system has cooled and/or the flue system

resistance is reduced. The Table lists the approximate water column negative pressure

readings and switch setpoints for sea level operating conditions.

DANGER

Safe operation of this unit requires proper venting flow. NEVER bypass combustion air proving

switch or attempt to operate the unit without the venter running and the proper flow in the vent

system. Hazardous conditions could result. See Hazard Levels, page 2.

Start-Up Cold

-1.0" w.c.

Equilibrium

-0.60" w.c.

Set Point "Off"

-0.48" w.c.

Set Point "On"

-0.65" w.c.

Access

to limit

switch

from

"outside"

the

furnace

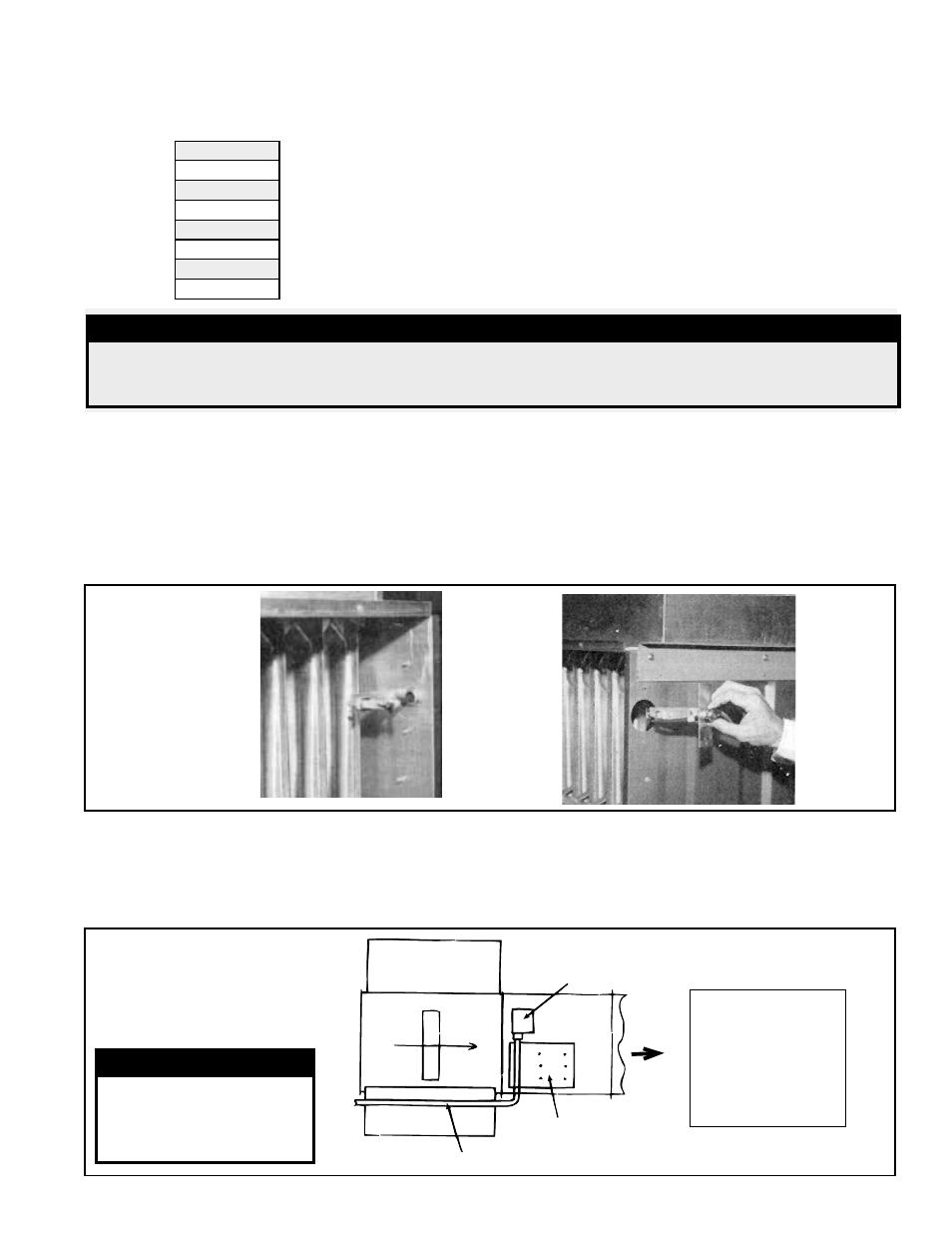

8.2 Limit Switch

View

of limit

switch

from

"inside"

the furnace

FIGURE 19 -

Access to the

limit switch

depends on the

installation.

A non-adjustable high limit switch mounted at the outlet air side of the heat exchanger

acts to shut off the gas supply in the event of air handler motor failure, lack of correct

airflow (See Paragraph 6.3), or restriction due to filters and/or duct design. See

FIG-

URE 19 for mounting and service.

Depending on accessibility, the limit switch may be serviced from either the outside of

the unit or from the inside through the access panel in the discharge duct. When units

are installed side by side, the service access panel must be in either the top or bottom

of the ductwork for limit switch service. (See Paragraphs 3.2.3 and 6.3.4.)

8.3 Fan Control

(Optional, Field

Installed)

FIGURE 20A - Installation

of Optional Fan Control Kit,

Option CQ1 (P/N 57960)

Option CQ1 Fan Control, P/N 147611,

Honeywell Model L4064A1347

Inspection

Panel

Field-supplied electric conduit for line voltage

wiring to the field-supplied blower.

Airflow

Direction

Fan Control Option CQ1

is rated for maximum

motor size of 3/4HP,

1Ph @ 115 or 230 VAC.

Larger motors or 3Ph

require use of a contactor

or starter.

Recommended dial setting

for most conditions is

130°F ON and 100°F OFF.

WARNING

If you turn off the power

supply, turn off the gas.

See Hazard Levels, page

2.

NOTE: Required with makeup air gas control options; see Paragraphs 8.4.3 and 8.4.4.

1. Fan control provides the following: a) Delay of fan operation preventing circulation

of cold air, and b) Fan operation as long as the unit is hot.

2. The fan control provides additional safety by keeping the fan in operation in the

event that the gas valve fails to close when the thermostat is satisfied.