Figure 15a - connecting ductwork to the furnace – Reznor EEDU Unit Installation Manual User Manual

Page 17

Form I-EEDU, P/N 150492 R6, Page 17

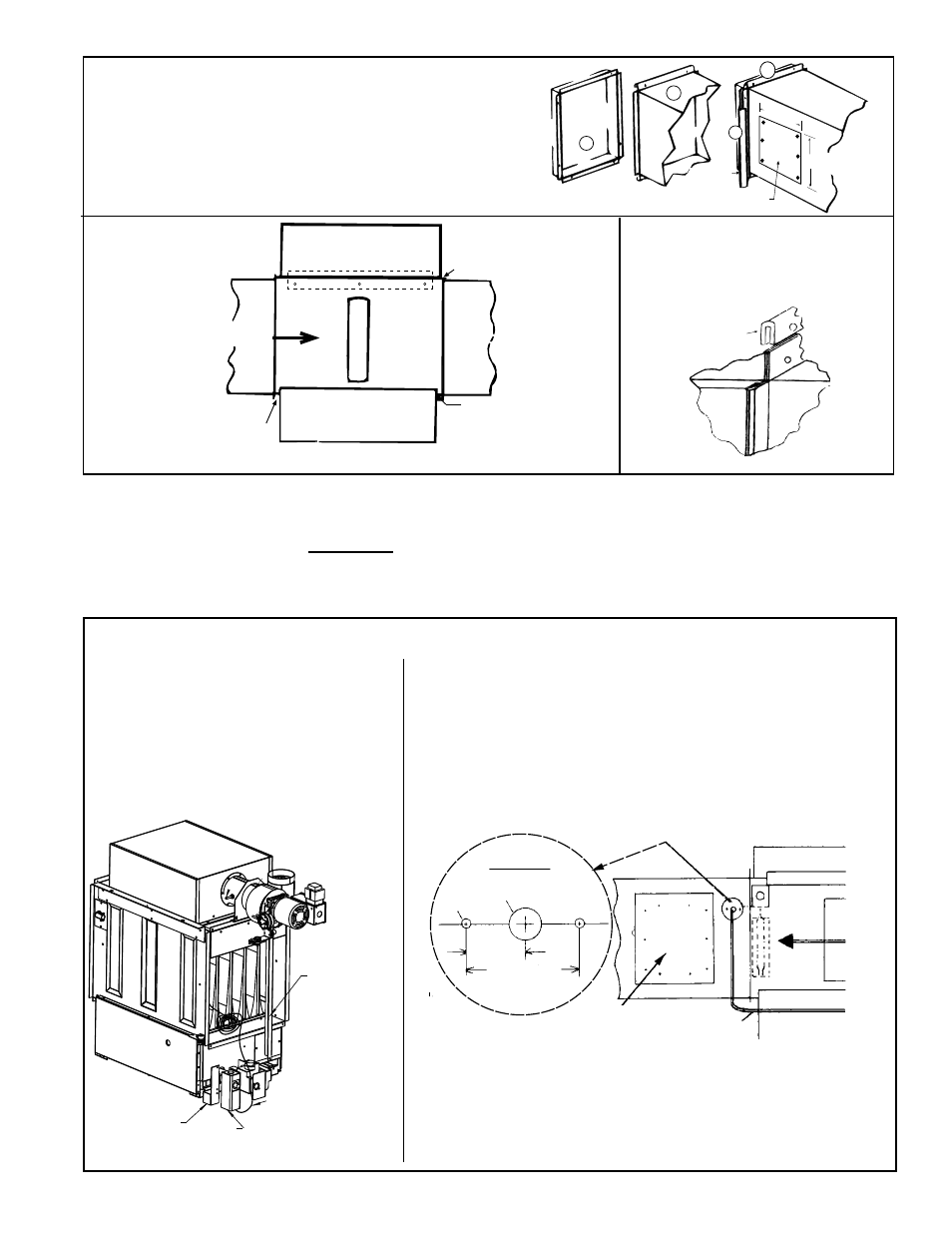

FIGURE 15A - Connecting Ductwork to the Furnace

1) Flanges on the heater turn out as shown.

2) Shape duct connection as shown -- "U" on top and bottom;

"L" on sides.

3) Slide "U" form over heater flange making connection.

4) Form "U" strips to seal ends. Drill and lock with sheetmetal

screws.

Heater

Duct

Access Panel in Duct

6

(152mm)

10 (254mm)

1

2

3

U

Channel

4

Furnace

U Channel of

Light Gauge Metal

Duct

Joints where ducts attach to

the furnace must be sealed

securely to prevent air leakage

which may disturb combustion.

Excessive leakage

here could have an

effect on combustion

causing premature damage to the heat exchanger and/or causing delayed ignition.

Air Flow

Direction

Warm air leakage here

would have an adverse

effect on combustion.

FIGURE 15C - The seals

between the furnace and the

duct must be mechanical. "U"

channel method as illustrated.

FIGURE 15B -

Attachment

of Duct to

Furnace

6.3.5 Discharge Air

Sensor for Makeup Air

Application

Option AG3 (two-stage makeup air) - The unit-mounted ductstat has a capillary tube

with a sensor bulb. The capillary and bulb must be moved out the way before install-

ing ductwork and then field-installed in the discharge duct. Refer to

FIGURE 16A and

follow the instructions.

All makeup air options (Options AG3, AG15, AG8, and AG9) require that the sensor be

field-installed in the discharge ductwork. Follow the instructions that apply.

Shipping

Angle -

Remove

before

attaching

ductwork.

Ductstat Bracket

- Option AG3

Ductstat -

Option AG3

Ductstat Capillary with

sensing bulb attached

inside the furnace. To

connect ductwork, remove

the bulb with the bracket.

(Save bracket and clip.)

FIGURE 16A - Installing Capillary Sensor Bulb in Discharge Ductwork (Option AG3)

The ductstat and the sensor are connected

by a permanently attached capillary tub-

ing. Before attaching ductwork, remove the

capillary tubing sensor bulb with the bracket

from its shipping position on the inside of

the furnace. After the ductwork is attached

to the furnace, follow the instructions on

the right to install the sensor bulb in the dis-

charge duct.

1/2” Diameter

1/8” Dia

3/4”

(19mm)

1-1/2” (38mm)

Capillary Tubing

to Ductstat

Airflow

Hole Pattern

Access

Panel

Instructions to Install Sensing Bulb in the Discharge Duct

Since the sensor is larger than the tubing, a gasket and gasket retainer

plate are needed to plug the hole and protect the capillary tubing

where it passes through the ductwork. These parts were shipped loose

with the furnace (See Paragraph 3.2). Two field-supplied sheetmetal

screws will be needed to attach the plate.

1) Drill the Holes - Refer to the illustration below and select a location on

the ductwork so that a minimum length of capillary tubing will be inside the

ductwork. Following the "hole pattern", drill holes in the ductwork.

Remove the ductwork access panel (

FIGURE 15A).

2) Install the Sensor - Remove the sensor bulb from the bracket. Push the

sensor through the 1/2" hole. Reaching through the access hole, use the

retaining clip to re-attach the sensor to the bracket.

3) Install the Gasket and Retainer Plate - Slide the gasket (cut a slit) and

hole retainer plate over the capillary tubing. With the gasket next to the

ductwork, attach the hole retaining plate with field-supplied sheetmetal

screws (as illustrated above). Close the ductwork access panel.