Reznor EEDU Unit Installation Manual User Manual

Page 27

Form I-EEDU, P/N 150492 R6, Page 27

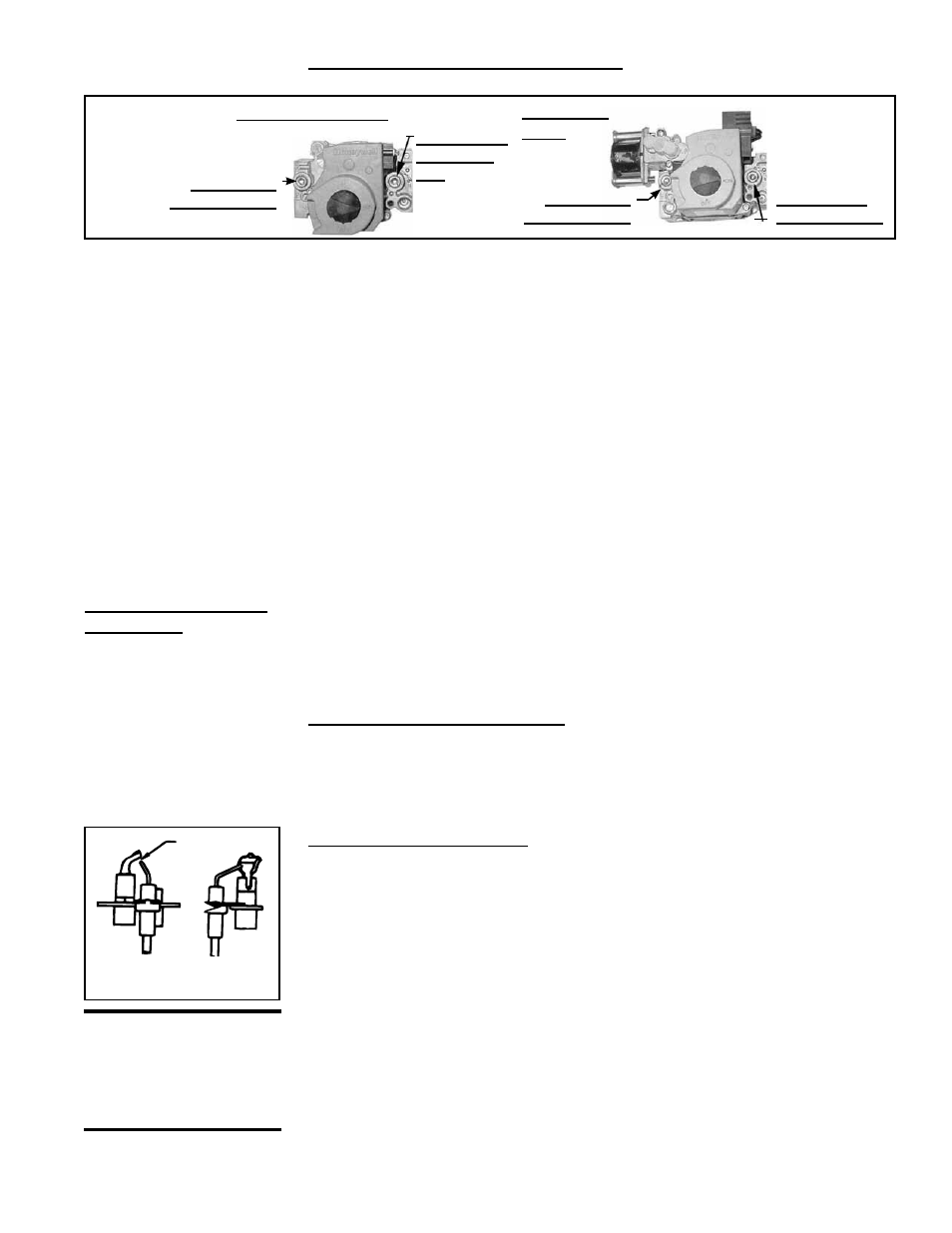

Single-Stage Valve

1/8" INLET

Pressure Tap

1/8” Outlet

Pressure

Tap

FIGURE 25 -

Gas Valve

Shutoff

Check

Instructions for Required Gas Valve Check:

1) Locate the 1/8” FPT INLET pressure tap on the combination valve (FIGURE 25).

1/8” Outlet

Pressure Tap

Two-Stage

Valve

1/8" INLET

Pressure Tap

1. Turn off the gas supply.

2. Turn off the electric supply.

3. Remove bottom rear panel (located on the manifold side of the furnace) by

removing the two screws from each side.

4. Mark and disconnect electric valve leads.

6. Uncouple the union in the gas supply.

7. Remove two sheetmetal screws in the bottom of the burner rack assembly.

8. Pull "drawer-type" burner rack out of the furnace.

To disassemble the burner rack:

1. Remove flash carryover system (screws located at rear of burner drawer).

2. Remove burner hold down clamp (located inside burner drawer under the pilot).

3. Pull main burners horizontally away from injection opening and lift out.

Follow the instructions below to clean. To re-assemble and replace, reverse the above

procedures being careful not to create any unsafe conditions.

Cleaning Pilot and Burners

Pilot - The pilot is located under the aeration panel on the control end of the burner tray

and is accessible only after the burner rack assembly has been removed. In the event

the pilot flame is short and/or yellow, check the pilot orifice for blockage caused by lint

or dust accumulation. Remove the pilot orifice and clean with air pressure. DO NOT

REAM THE ORIFICE. Check and clean the aeration slot in the pilot burner.

Clean the metal sensing probe and the pilot hood with an emery cloth and wipe off the

ceramic insulator. Check the spark gap; spark gap should be maintained to .100". After

the pilot is cleaned, blow any dirt away with compressed air. The combination valve

includes a pilot adjustment screw. To adjust, remove cap screw and adjust the pilot

flame to approximately 1-1/4".

Pilot System - No periodic maintenance of the ignition control box is required. How-

ever, each season the lead wires should be checked for insulation deterioration and

good connections. Proper operation of the electronic spark ignition system requires

a minimum flame signal of 0.2 microamps as measured by a microampmeter. Do not

attempt to disassemble the ignition controller. There are no field replaceable compo-

nents in the control enclosure.

CAUTION: Due to

high voltage on pilot

spark wire and pilot

electrode, do not

touch when energized.

10.2.2 Burner Rack and

Pilot

Burner Rack Removal

Instructions

.100 spark

gap

FIGURE 26 - Pilot

Burner Spark Gap

NOTE: Operational

pressure settings and

instructions for checking

pressure settings are in

Paragraph 6.1.

2) With the manual valve turned off to prevent flow to the gas valve, connect a

manometer to the 1/8” inlet pressure tap in the valve.

NOTE: A manometer (fluid-

filled gauge) with an inches water column scale is recommended.

3) With the field-installed manual valve remaining closed, observe the manometer

for two to three minutes for an indication of gas pressure. No pressure should be

indicated on the manometer.

If the manometer indicates a gas pressure, the field-installed manual gas valve

must be replaced or repaired before the combination gas valve can be checked.

4) If the manometer does not indicate gas pressure, slowly open the field-installed

manual gas valve. After the manometer's indicated gas pressure has reached

equilibrium, close the manual shutoff valve. Observe the gas pressure. There

should be no loss of gas pressure on the manometer. If the manometer indicates

a loss of pressure, replace the combination gas valve before placing the heater in

operation.