Two-servo system construction (6 steps) – Carl Goldberg GBGA0055 User Manual

Page 24

24

35.

■

■

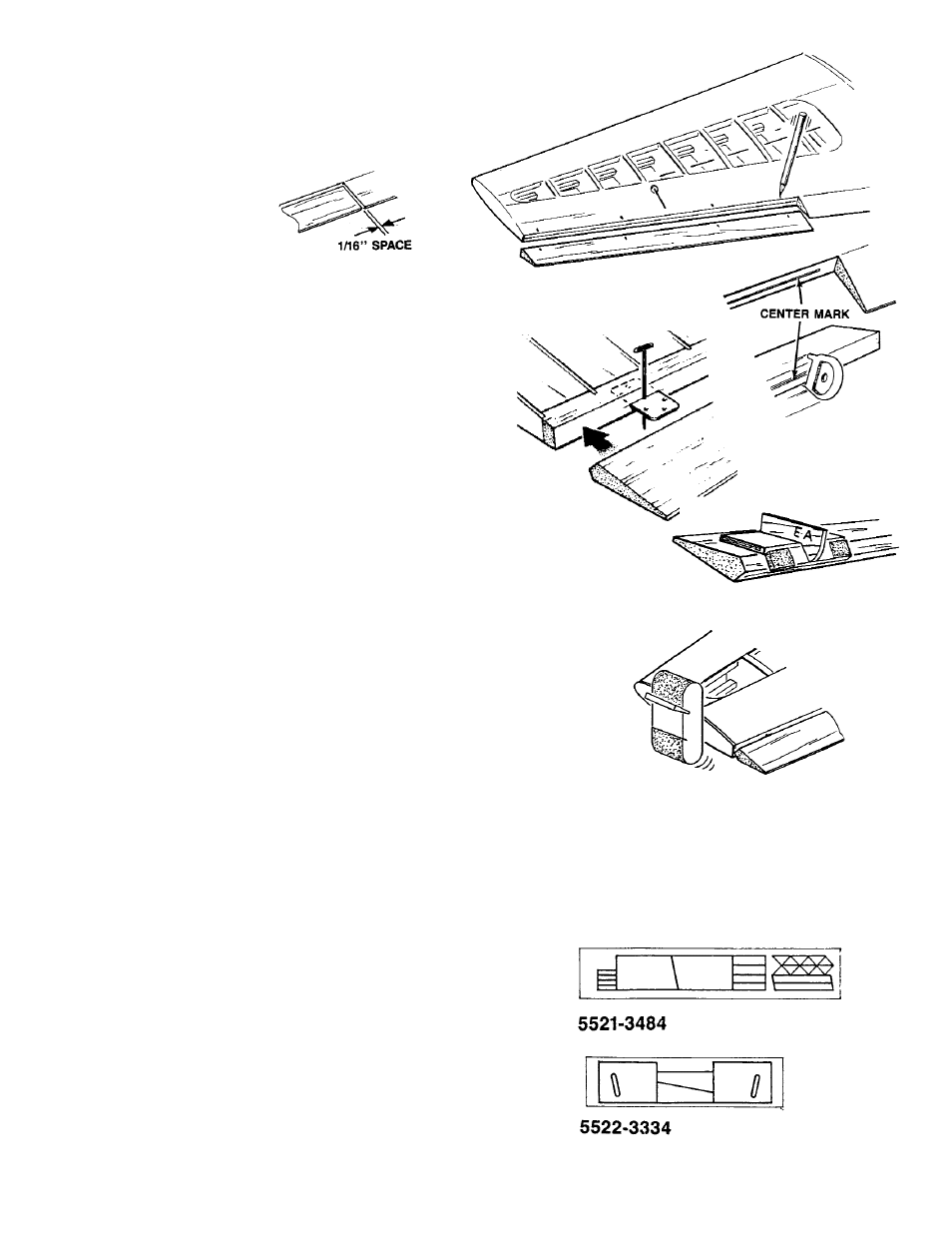

At this time, transfer hinge locations from the plan to

the ailerons. Next, transfer these marks to the wing. Be

sure to leave a 1/16” gap between the aileron and the

T.E. center section.

■

■

Use a CGM centerline tool and scribe a hinge

centerline into both ailerons and wing halves.

■

■

Hinge the ailerons just like you did the elevator and

rudder

■

■

Bevel the ailerons to the center scribe line, using the

bevel tool marked “AE.”

■

■

Temporarily hinge the ailerons to the wing to test the

fit. Then, sand the aileron to the tip plane of the wing.

NOTE:

Permanent assembly of the ailerons to the wings,

as well as control horn installation, is done after

covering.

IF YOU ARE INSTALLING ONLY ONE SERVO, THE WING

CONSTRUCTION IS NOW COMPLETE.

NOTE:

The two-servo option should be used for aircraft

using an engine larger than a .60 2-cycle.

1.

■

■

Collect the following parts needed to install an aileron

servo in each wing panel.

(1) D/C SHT. #5521 PLY

PT. #3484

CONTAINING SERVO MOUNTING PARTS

(1) D/C SHT. #5522 BALSA

PT. #3334

CONTAINING HATCH COVERS

(16) #2 x 5/16” SHT. METAL SCREW

PT. #1086

(16) #2 WASHER

PT. #1138

TWO-SERVO SYSTEM CONSTRUCTION (6 Steps)

TO BE INSTALLED ON A COMPLETED WING