Carl Goldberg GBGA0040 User Manual

Page 26

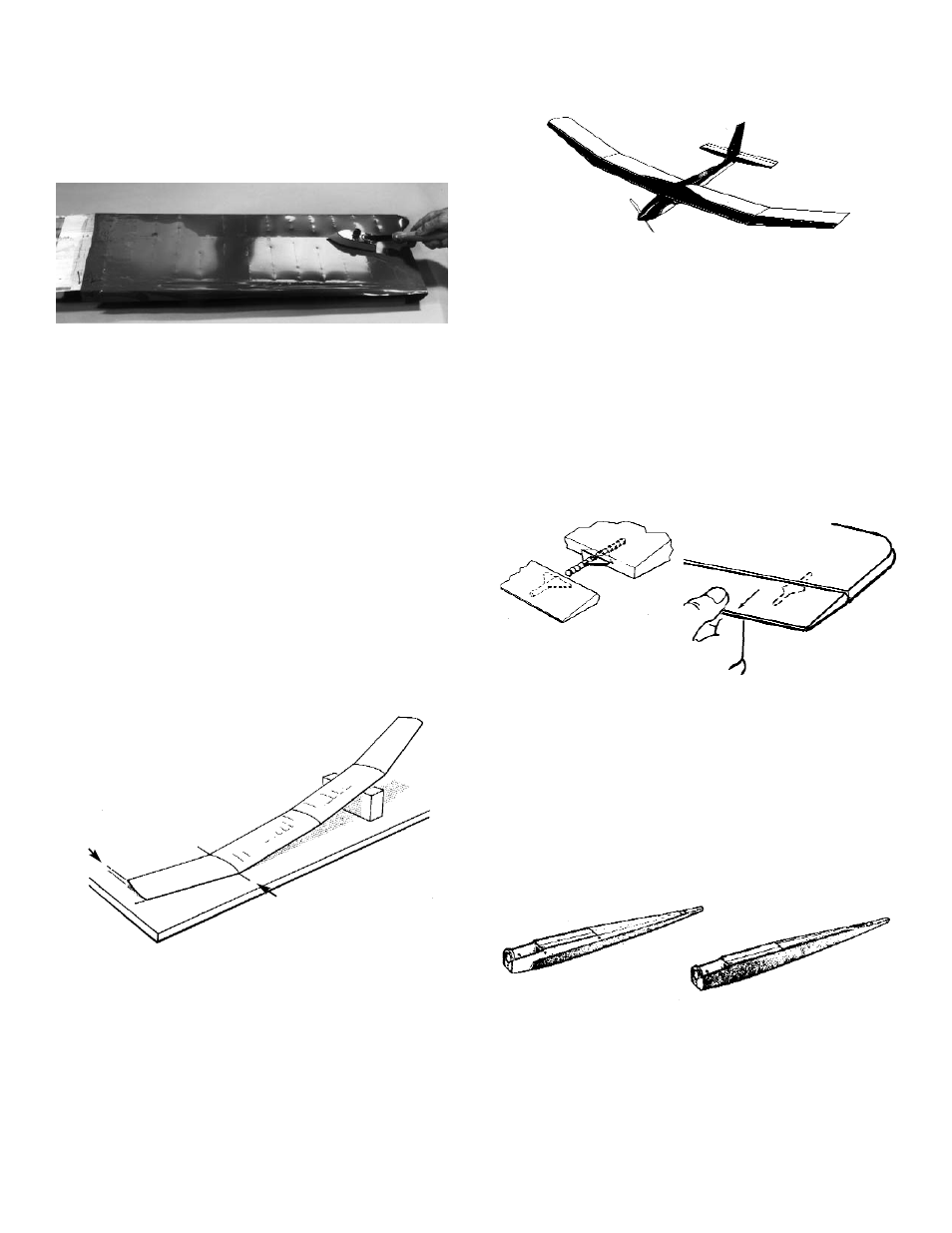

Work from the center out and tack to the ribs, sheeting,

and other wood surfaces, using medium heat. Gently

rub the covering with a soft cloth to help set it in place.

Press the covering around the edges, again rubbing

with a cloth and making sure to apply enough pressure

to work the adhesive into the wood.

For inside corners, follow the instruction that come with

your covering, as different materials may require slight-

ly different techniques.

Using your iron (or a special covering "heat gun,") set

at relatively high heat, shrink the covering tight. Neatly

trim off any surplus.

Following the same procedure, cover the remainder of

the wing bottom and then cover the wing top. Be sure

to overlap all seams at least ¼". Remember that there

must be sufficient overlap to allow for the shrinkage

when high heat is applied.

TRUING THE WING

IMPORTANT: After the wing has been covered, you

must check to make sure it is free of warps. This is a

very critical step and should not be rushed or omit-

ted.

To detect warp,.set each section of the wing on a flat

surface and make certain the panel sits flat. To count-

er any warp, twist panel slightly in the direction oppo-

site to the warp and hold this position while gliding the

iron over the covering to re-tension the structure.

Repeat process until the panel is true. NOTE: The wing

tip will rise up about 1/4 from the flat surface.

COVERING THE FUSELAGE

For added realism, the cabin interior may be painted

now, before the pieces are covered. Use UltraPaint™

or even auto primer.

Cut pieces of covering for the fuse bottom, sides, and

top. Again, make sure the pieces are large enough to

allow for overlap.

COVERING THE TAIL

Cover all tail components (the stabilizer, the elevator,

the fin, and the rudder), following the same procedure

as with the wing. The component pieces should each

be covered separately, before assembly. Then, the

covering should be carefully removed from the areas

to be glued, so that a strong WOOD-SURFACE-TO-

WOOD-SURFACE adhesion is achieved.

IMPORTANT: Once the tail sections have been cov-

ered, and while the hinge locations are still fresh in

your memory, IMMEDIATELY slit the covering to open

up the hinge slots. (Refer to the plan for help in locat-

ing the hinge slots.)

After locating and opening the hinge slots, insert and

glue a hinge into each of the stab slots. Let the glue

wick into the slots and allow to dry. Then, attach the

elevators by inserting the other half of each hinge into

the elevator slots. Again, glue and allow to dry.

Repeat this procedure to attach the rudder to the fin.

When the glue has dried, firmly pull at each hinge loca-

tion to make sure the bond is secure. FAILURE TO

FIRMLY INSTALL HINGES CAN LEAD TO LOSS OF

CONTROLL AND A CRASH. Periodically check con-

trol surfaces to make sure the bond has not weakened.

26

1/4” WASHOUT

POLYHEDRAL JOINT