Troubleshooting – AERCO KC1000 Heater Mar 2011 User Manual

Page 67

TROUBLESHOOTING

7-3

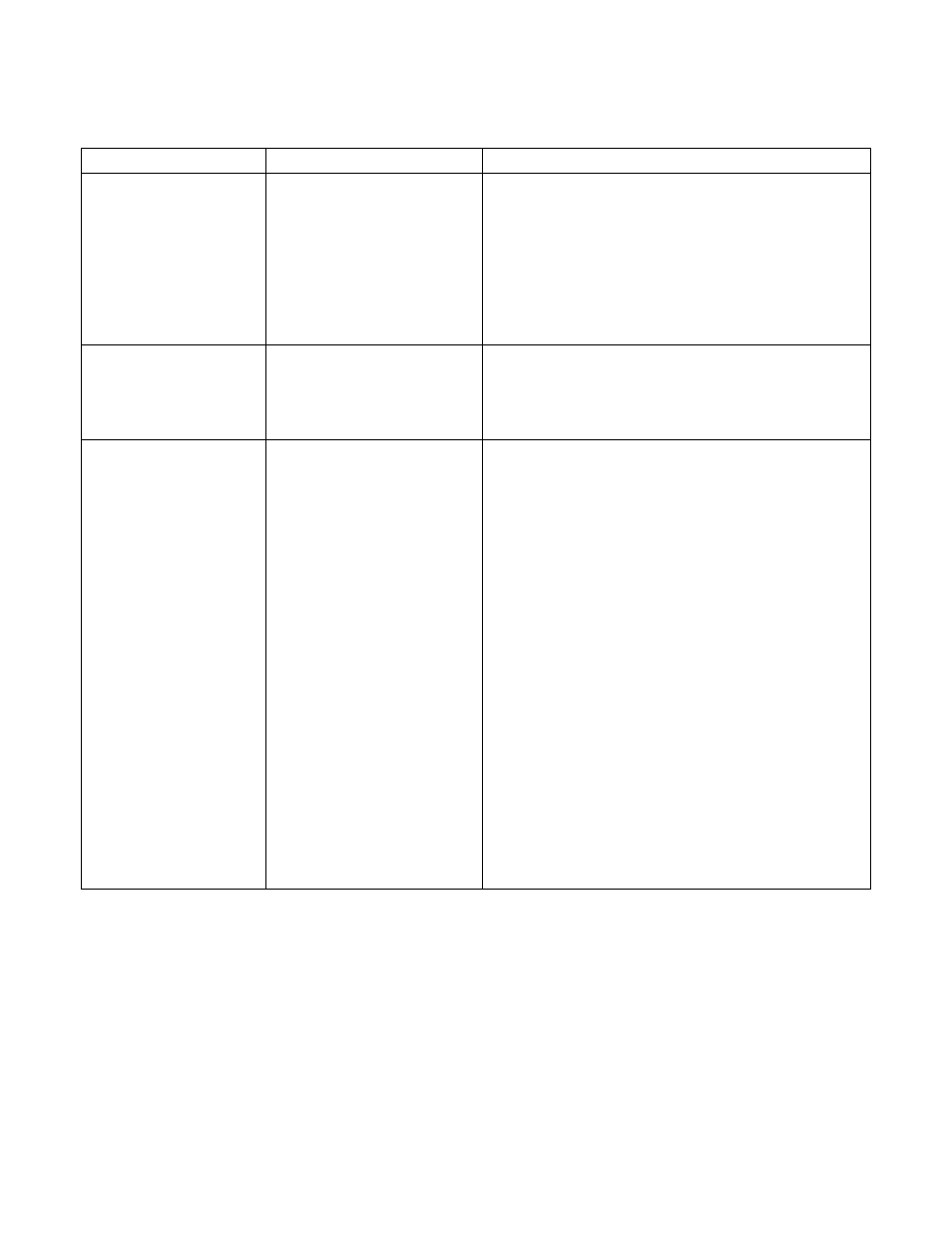

KC1000 WATER HEATER TROUBLESHOOTING TABLE – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

DELAYED

INTERLOCK OPEN

1. Delayed Interlock Jumper

not installed or removed.

2. Device proving switch

hooked to interlocks is not

closed

1. Check for a jumper properly installed across the

delayed interlock terminals in the I/O box.

2. If there are 2 external wires on these terminals,

check to see if an end switch for a device such as a

pump, louver, etc. is tied these interlocks. Ensure

that the device and or its end switch are functional.

(jumper may be temporarily installed to test

interlock)

DIRECT DRIVE

SIGNAL FAULT

1. Unit “Type” is improperly

set up as Boiler instead

of Water Heater.

1. Check the “Unit Type” menu option in the

Configuration Menu to ensure that the Unit Type is

set to Water Heater. Change menu option if

necessary.

FLAME LOSS

DURING IGN

1. Worn flame detector

2. No spark from Spark Plug

3. Defective Ignition

Transformer

4. Defective Ignition/Stepper

(IGST) Board

5. Defective SSOV

6. Defective Differential

Pressure Regulator

7. Carbon or other debris on

Burner

8. Staged ignition ball valve

closed.

1. Remove and inspect the flame detector for signs of

wear. Replace if necessary.

2. Close the internal gas valve in the boiler. Install

and arc a spark ignitor outside the unit.

3. If there is no spark, check for 120VAC at the

primary side to the ignition transformer during the

ignition cycle.

4. If 120VAC is not present, the IGST Board in the

Control Box may be defective. Refer fault to

qualified service personnel.

5. While externally arcing the spark ignitor, observe

the open/close indicator in the Safety Shut-Off

Valve to ensure it is opening. If the valve does not

open, check for 120VAC at the valves input

terminals. If 120VAC is not present, the IGST

board in the Control Box may be defective. Refer

fault to qualified service personnel.

6. Check gas pressure readings using a gauge or

manometer into and out of the Air/Fuel Valve to

ensure gas is getting to the burner.

7. Remove the burner and inspect for any carbon or

debris. Clean and reinstall.

8. Open ¼” ball valve downstream of SSOV.