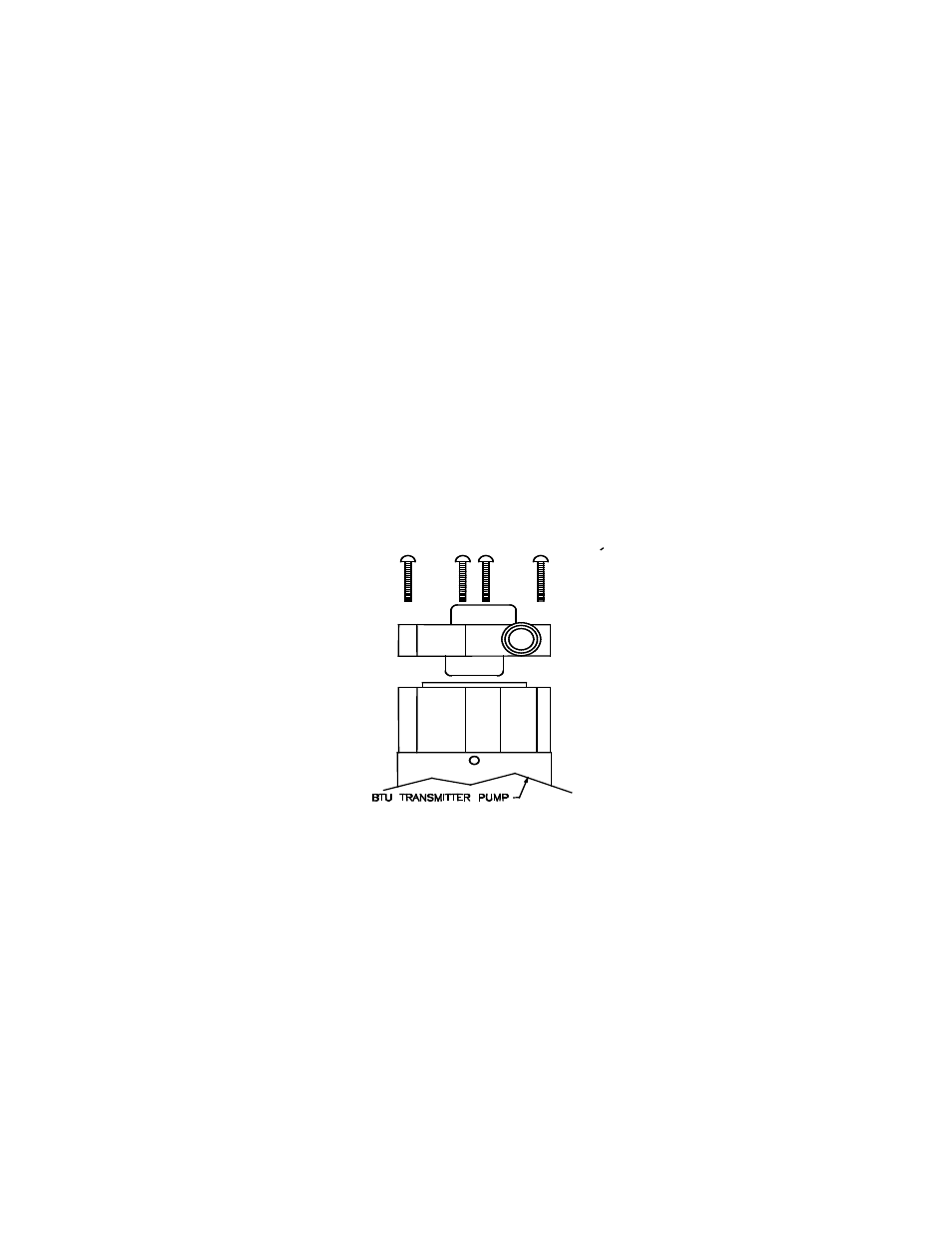

7 btu transmitter assembly, Figure 6.3, Btu transmitter pump disassembly – AERCO KC1000 Heater Mar 2011 User Manual

Page 48: Maintenance

MAINTENANCE

6-4

6.7 BTU TRANSMITTER ASSEMBLY

The BTU Transmitter is a crucial part of the unit’s temperature control system. It must be inspected and

kept free of scale and debris in order for the unit to maintain accurate outlet water temperatures.

To inspect the transmitter:

1. Place the

ON/OFF switch in the OFF position.

2. Remove the sheet metal side panels and hood from the unit.

3. Shut the water inlet, outlet and recirculation valves to the unit.

4. Open the drain valve on the unit.

5. Slowly open the pressure relief valve to allow air-flow into the unit.

6. Fully drain the unit.

7. Disconnect electrical power from the unit.

8. Remove the 4 screws holding the BTU transmitter pump to the impeller housing. Remove and set the

pump aside, (See Fig. 6.3).

NOTE:

It is not necessary to disconnect the electrical wires to the pump.

Figure 6.3

BTU Transmitter Pump Disassembly

9. Using a 5/8” and 9/16” wrench, loosen the 4 compression fittings holding the lower tubing assembly in

place, (See Fig. 6.4).

- AERClean (12 pages)

- ProtoNode Gateway Rev 1 (with internal LEDs) (64 pages)

- ProtoNode Gateway Rev 3 (with external LEDs) (126 pages)

- Control System (ACS) (144 pages)

- Belimo F6...HD/HDU Series Valve (44 pages)

- Belimo AF120-S US Actuator (9 pages)

- Belimo AMX24-MFT Actuator (9 pages)

- Belimo GKX24-MFT Actuator (9 pages)

- Belimo Motorized Valves Installation (20 pages)

- BMS II BOILER (108 pages)

- BMS II BOILER MODBUS Communication (100 pages)

- BMS 168 (86 pages)

- Boiler Valve Controller (BVC) PRIOR to Serial-12-840-1 (35 pages)

- Boiler Valve Controller (BVC) (38 pages)

- Buffer Tanks (14 pages)

- Combination Control Panel (CCP) (4 pages)

- XPC GATEWAY Communications (193 pages)

- Domestic Water Storage Tank (19 pages)

- Steam Traps (6 pages)

- X100 – Inhibitor (4 pages)

- AM Series Boiler User Manual (156 pages)

- AM Series Boiler Cascade Sequencer Controller (26 pages)

- AM Series Boiler Modbus Interface Manual (18 pages)

- BMK 1.5 LN October 2012 (166 pages)

- BMK 1.5 LN July 2011 (152 pages)

- BMK 1.5 LN June 2010 (123 pages)

- BMK 1.5 LN May 2009 (111 pages)

- BMK 1.5 LN Dual Fuel Feb 2013 (162 pages)

- BMK 1.5 LN Dual Fuel June 2010 (139 pages)

- BMK 1.5 LN Dual Fuel Jan 2009 (126 pages)

- BMK 1500-2000 (188 pages)

- BMK 1500DF (196 pages)

- C-More Control Panel (162 pages)

- BMK 2.0 LN October 2012 (172 pages)

- BMK 2.0 LN Natural Gas (SN G-11-1861 and above) (170 pages)

- BMK 2.0 LN Nat. Gas June 2010 (125 pages)

- BMK 2.0 LN Natural Gas 2008 (111 pages)

- BMK 2.0 LN Nat. Gas for Mass. only (113 pages)

- BMK 2.0 LN Dual Fuel Serial G-11-2402 and UP (160 pages)

- BMK 2.0 LN Dual Fuel Nov 2010 (139 pages)

- BMK 2.0 LN Nat. Gas (112 pages)

- BMK 2.0 LN for Mass. only (114 pages)

- BMK 3.0 LN Dual-Fuel Series Gas Fired Low NOx Boiler System (136 pages)

- BMK 3.0 LN Natural Gas July 2011 (129 pages)

- BMK 3.0 LN Nat. Gas Jan 2011 (129 pages)