AERCO BMK 1000 User Manual

Page 21

Benchmark 750/1000 Boiler Installation, Operation & Maintenance Manual

CHAPTER 2 – INSTALLATION

OMM-0082_0J

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 21 of 192

GF-130

Ph.: 800-526-0288

05/21/2014

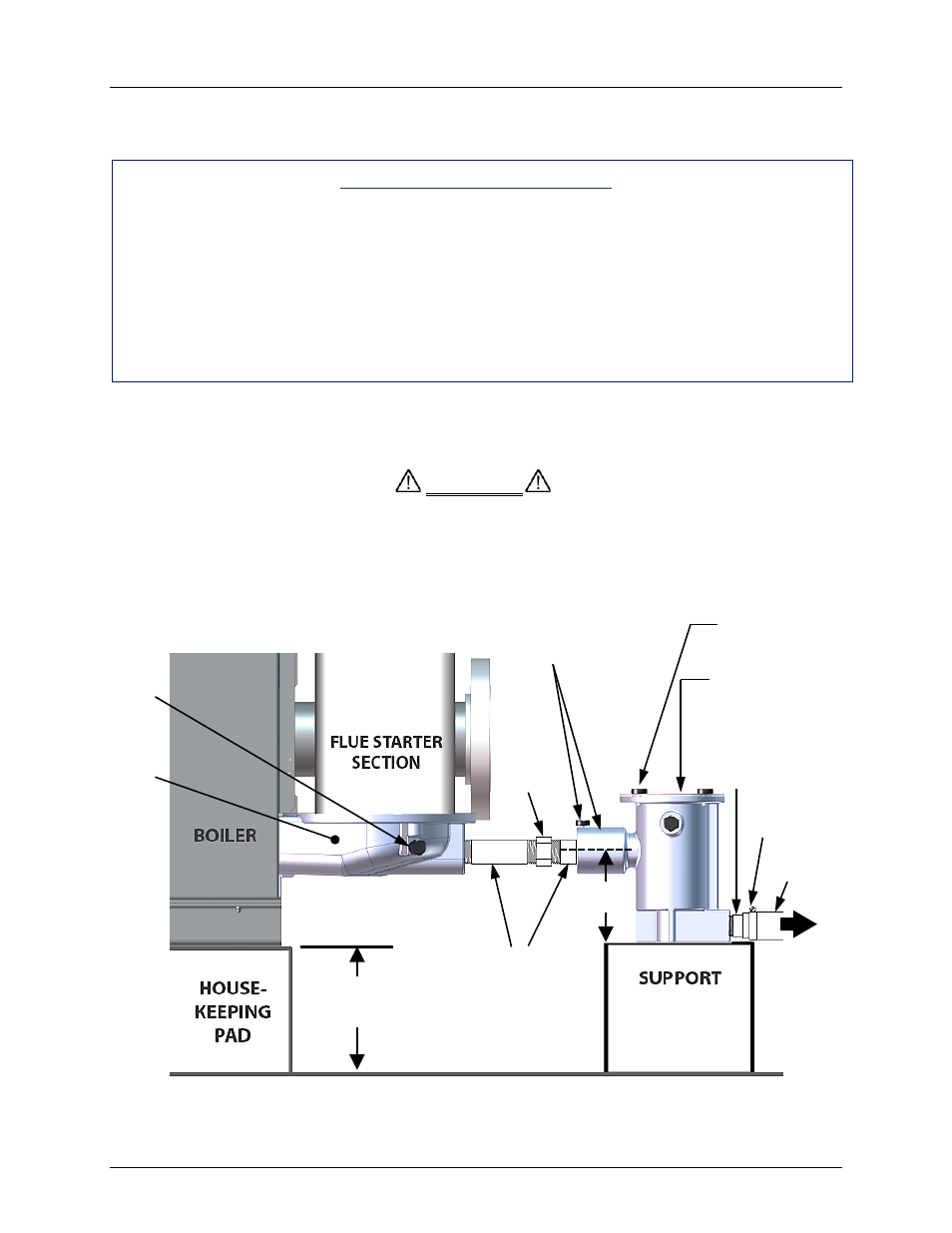

While observing the above guidelines, install the condensate trap as follows:

Condensate Trap Installation

1.

Connect the condensate trap inlet to the exhaust manifold drain connection using the

appropriate piping components (nipples, reducers, elbows, etc.) for the boiler installation

site.

2.

At the condensate trap outlet, install a 3/4” NPT nipple.

3.

Connect a length of 1” I.D polypropylene hose to the trap outlet and secure with a hose

clamp.

4.

Route the hose on the trap outlet to a nearby floor drain.

If a floor drain is not available, a condensate pump can be used to remove the condensate to an

appropriate drain. The maximum condensate flow rate is 10 GPH. The condensate drain trap,

associated fittings and drain line must be removable for routine maintenance.

Use PVC, stainless steel, aluminum or polypropylene for condensate drain

piping (Figure 2-6). DO NOT use carbon or copper components.

Figure2-6: Sample Condensate Trap Installation

CAUTION

COMBUTION

ANALYZER

PROBE PORT

EXHAUST

MANIFOLD

3/4” NPT

NIPPLE

HOSE

CLAMP

T O

FLOOR

DRAIN

CONDENSATE

TRAP

(P/N 24060)

TRAP INLET

INTEGRAL ADAPTOR AND

THUMBSCREW

TOP COVER

THUMB SREWS

(4 each)

1” DIAM.

HOSE

NOTE

HOUSKEEPING

PAD MUST NOT

EXTEND

UNDER THE

CONDENSATE

ASSEMBLY.

4” MINIMUM

(6” MAXIMUM)

4”

3/4” NPT

NIPPLES

UNION