AERCO BMK 1000 User Manual

Page 106

Benchmark 750/1000 Boiler Installation, Operation & Maintenance Manual

CHAPTER 8 – TROUBLESHOOTING GUIDE

Page 106 of 192

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0082_0J

05/21/2014

Ph.: 800-526-0288

GF-130

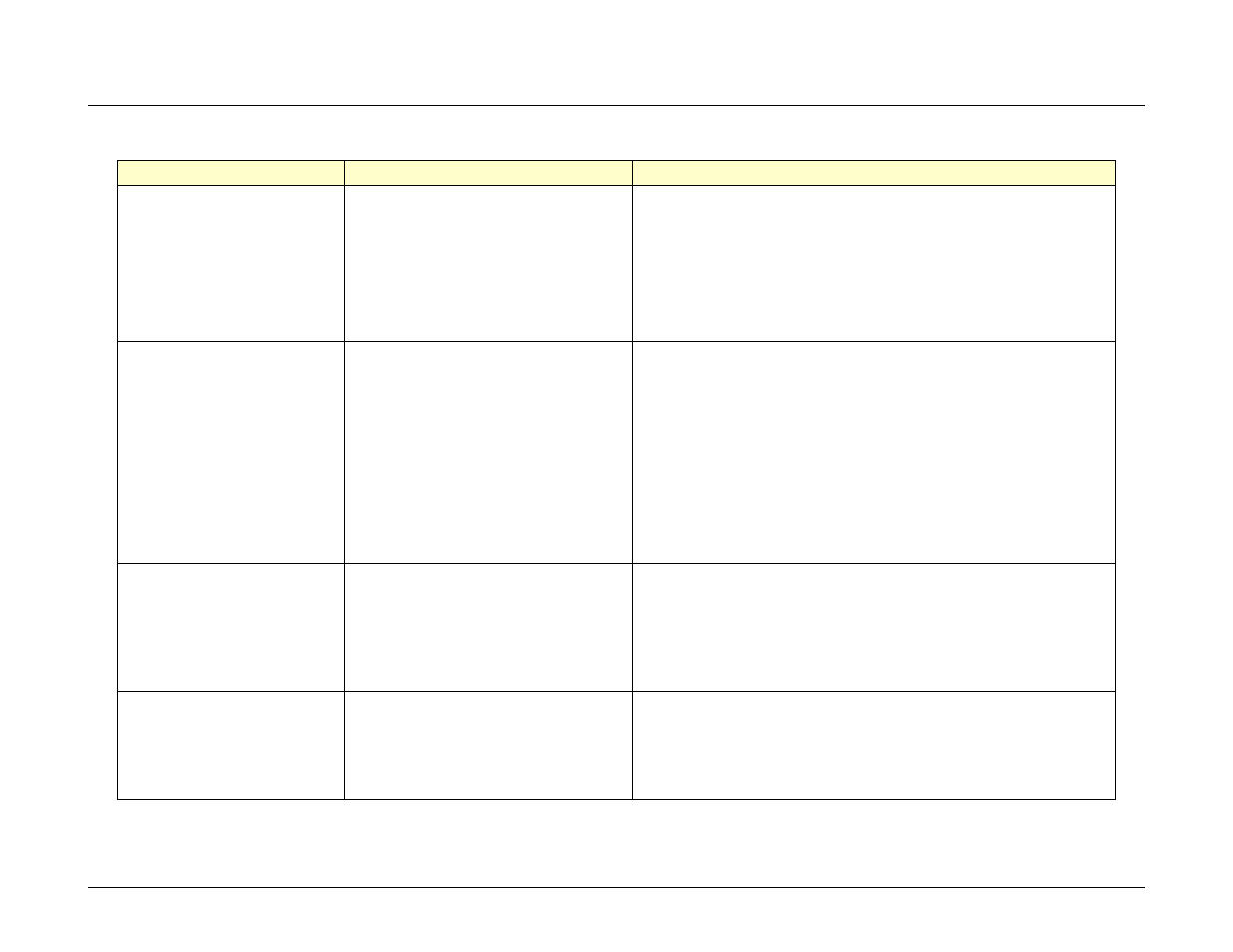

TABLE 8-1. BOILER TROUBLESHOOTING – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

FLAME LOSS

DURING IGN

(continued)

6.

Carbon or other debris on

Burner.

7.

Staged ignition solenoid valve

doesn’t open.

8.

Clogged staged ignition piece.

6.

Remove View-Port and inspect Burner with Boroscope. If it

is fouled or black with soot, remove the Burner and inspect

for any carbon build-up or debris. Clean and reinstall.

7.

When unit goes to ignition, listen for a clicking sound at the

staged ignition solenoid valve to ensure it is opening.

8.

Remove and inspect the igniter-injector and inspect the

gas injector for blockage.

FLAME LOSS

DURING RUN

1.

Worn Flame Detector or cracked

ceramic.

2.

Defective Regulator.

3.

Poor combustion calibration.

4.

Debris on burner.

5.

Blocked condensate drain.

1.

Remove and inspect the Flame Detector for signs of wear

or cracked ceramic. Replace if necessary.

2.

Check gas pressure readings using a gauge or manometer

into and out of the Air/Fuel Valve to ensure that the gas

pressure into and out of the valve is correct.

3.

Check combustion calibration using procedures in Chapter

4.

4.

Remove the burner and inspect for any carbon build-up or

debris. Clean and reinstall.

5.

Remove blockage in condensate drain.

HEAT DEMAND

FAILURE

1.

The Heat Demand Relays on the

Ignition/Stepper (IGST) board

failed to activate when

commanded.

2.

Relay is activated when not in

Demand.

1.

Press CLEAR button and restart the unit. If the fault

persists, replace Ignition/Stepper (IGST) Board.

2.

Defective relay. Replace IGST Board.

HIGH EXHAUST

TEMPERATURE

1.

Poor combustion calibration.

2.

Carboned heat exchanger due to

incorrect combustion calibration

1.

Check combustion calibration using procedures in Chapter

4.

2.

If exhaust temperature is greater than 200

o

F, check

combustion calibration. Calibrate or repair as necessary.