Initial start-up – AERCO BMK 2.0 LN Nat. Gas for Mass. only User Manual

Page 34

INITIAL START-UP

5. Attach one end of the plastic tubing to the

barbed fitting and the other end to the 16

inch W.C. manometer.

MANUAL

SHUT-OFF

VALVE

TO AIR/

FUEL

VALVE

GAS

INLET

1/8" NPT PLUG

(INSTALL

MANOMETER

HERE)

LOW GAS

PRESSURE

SWITCH

HIGH GAS

PRESSURE

SWITCH

SSOV

Figure 4-1.

1/8 Inch NPT Gas Plug Location

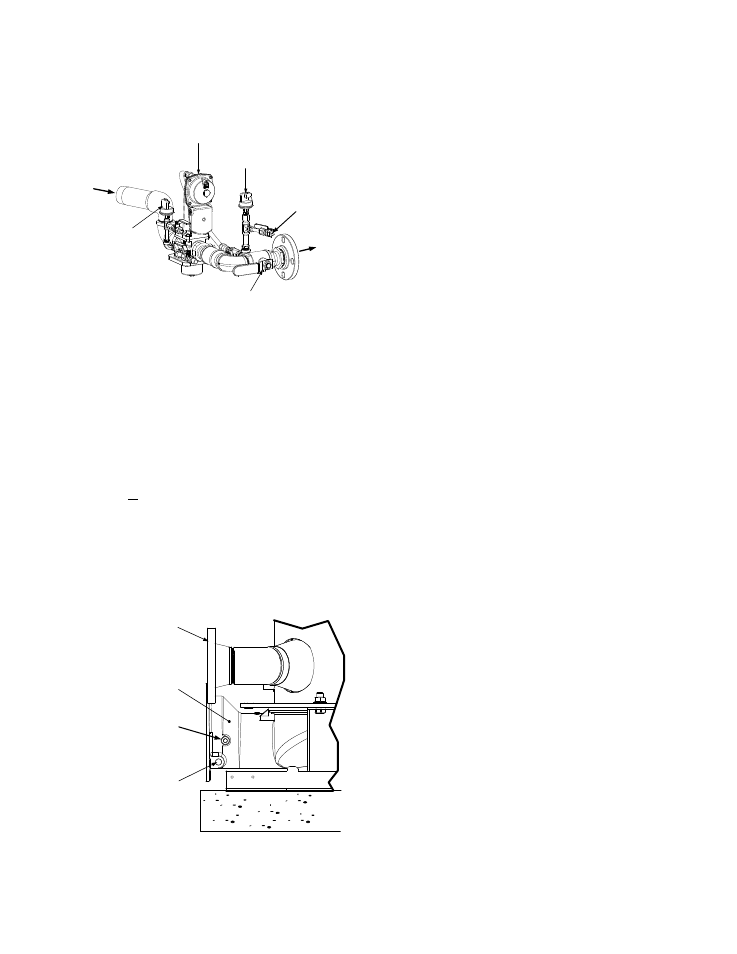

4.2.3 Accessing the Analyzer Probe Port

The unit contains NPT plugs on the left and right

side of the exhaust manifold at the rear of the

unit as shown in Figure 4-2. Prepare the port for

the combustion analyzer probe as follows:

1. Remove the plug from the probe port on the

left or right side of the exhaust manifold.

2. If necessary, adjust the stop on the

combustion analyzer probe so that it will

extend mid-way into the flue gas flow. DO

NOT install the probe at this time.

EXHAUST

MANIFOLD

1/2” NPT

CONDENSATE

DRAIN

CONNECTION

BOILER

RETURN

ANALYZER

PROBE PORT

Figure 4-2

Analyzer Probe Port Location

4.3 NATURAL GAS COMBUSTION

CALIBRATION

The Benchmark 2.0LN Boiler is combustion

calibrated at the factory prior to shipping.

However, recalibration as part of initial start-up

is necessary due to changes in the local altitude,

gas BTU content, gas supply piping and supply

regulators. Factory Test Data sheets are

shipped with each unit. These sheets must be

filled out and returned to AERCO for proper

Warranty Validation.

It is important to perform the following procedure

as outlined. This will keep readjustments to a

minimum and provide optimum performance.

1. Open the water supply and return valves to

the unit and ensure that the system pumps

are running.

2. Open the natural gas supply valve(s) to the

unit.

3. Set the control panel ON/OFF switch to the

OFF position.

4. Turn on external AC power to the unit. The

display will show LOSS OF POWER and the

time and date.

5. Set the unit to the Manual Mode by pressing

the AUTO/MAN key. A flashing Manual Fire

Rate

message will be displayed with the

present rate in %. Also, the MANUAL LED

will light.

6. Adjust the fire rate to 0% by pressing the ▼

arrow key.

7. Ensure that the leak detection ball valve

down-stream of the SSOV is open.

8. Set

the

ON/OFF switch to the ON position.

9. Change the fire rate to 29% using the ▲

arrow key. The unit should begin its start

sequence and fire.

10.

Next, verify that the gas pressure

downstream of the SSOV is 2.8” W.C. for

both FM and IRI gas trains. If gas pressure

adjustment is required, remove the brass

hex nut on the SSOV actuator (IRI gas train)

containing the droop eliminator (Figure 4-3).

Make droop eliminator adjustments using a

flat-tip screwdriver to obtain 2.8” W.C.

4-2