Control panel operating procedures – AERCO BMK 2.0 LN Nat. Gas for Mass. only User Manual

Page 24

CONTROL PANEL OPERATING PROCEDURES

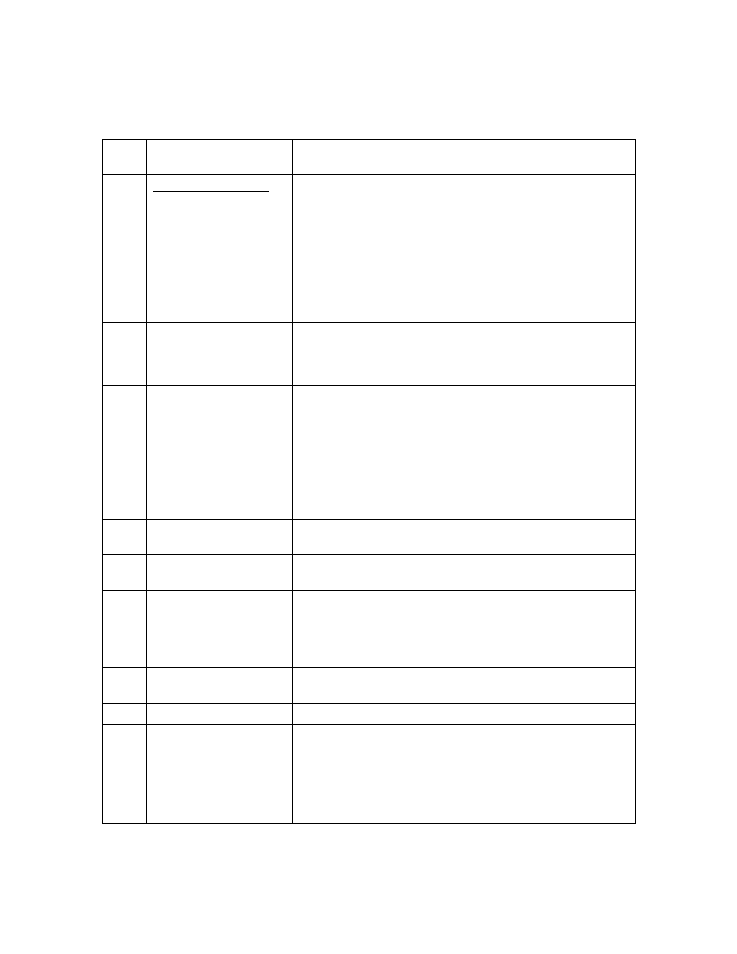

Table 3-1 Operating Controls, Indicators and Displays

ITEM

NO.

CONTROL, INDICATOR

OR DISPLAY

FUNCTION

1

LED Status Indicators

Four Status LEDs indicate the current operating status as

follows:

COMM

Lights when RS-232 communication is occurring

MANUAL

Lights when the unit is being controlled using the front panel

keypad.

REMOTE

Lights when the unit is being controlled by an external signal

from an Energy Management System

DEMAND

Lights when there is a demand for heat.

2

OUTLET

TEMPERATURE

Display

3–Digit, 7–Segment LED display continuously displays the

outlet water temperature. The °F or °C LED next to the

display lights to indicate whether the displayed temperature is

in degrees Fahrenheit or degrees Celsius.

3

VFD Display

Vacuum Fluorescent Display (VFD) consists of 2 lines each

capable of displaying up to 16 alphanumeric characters. The

information displayed includes:

Startup Messages

Fault Messages

Operating Status Messages

Menu Selection

4

RS-232

Port

Port permits a Laptop Computer or External Modem to be

connected to the unit’s Control Panel.

5

FAULT

Indicator

Red FAULT LED indicator lights when a boiler alarm

condition occurs. An alarm message will appear in the VFD.

6

CLEAR

Key

Turns off the FAULT indicator and clears the alarm message

if the alarm is no longer valid. Lockout type alarms will be

latched and cannot be cleared by simply pressing this key.

Troubleshooting may be required to clear these types of

alarms.

7

READY

Indicator

Lights ON/OFF switch is set to ON and all Pre-Purge

conditions have been satisfied.

8

ON/OFF

Switch

Enables and disables boiler operation.

9

LOW WATER LEVEL

TEST/RESET

Switches

Allows operator to test operation of the water level monitor.

Pressing TEST opens the water level probe circuit and

simulates a Low Water Level alarm.

Pressing RESET resets the water level monitor circuit.

Pressing the CLEAR key (item 6) resets the display.

3-2