Installation – AERCO BMK 2.0 LN Nat. Gas for Mass. only User Manual

Page 17

INSTALLATION

2-5

2.7.3 IRI Gas Train Kit

The IRI gas train is an optional gas train

configuration which is required in some areas for

code compliance or for insurance purposes.

The IRI gas train is factory pre-piped and wired.

See Appendix F, Drawing AP-A-843

for details.

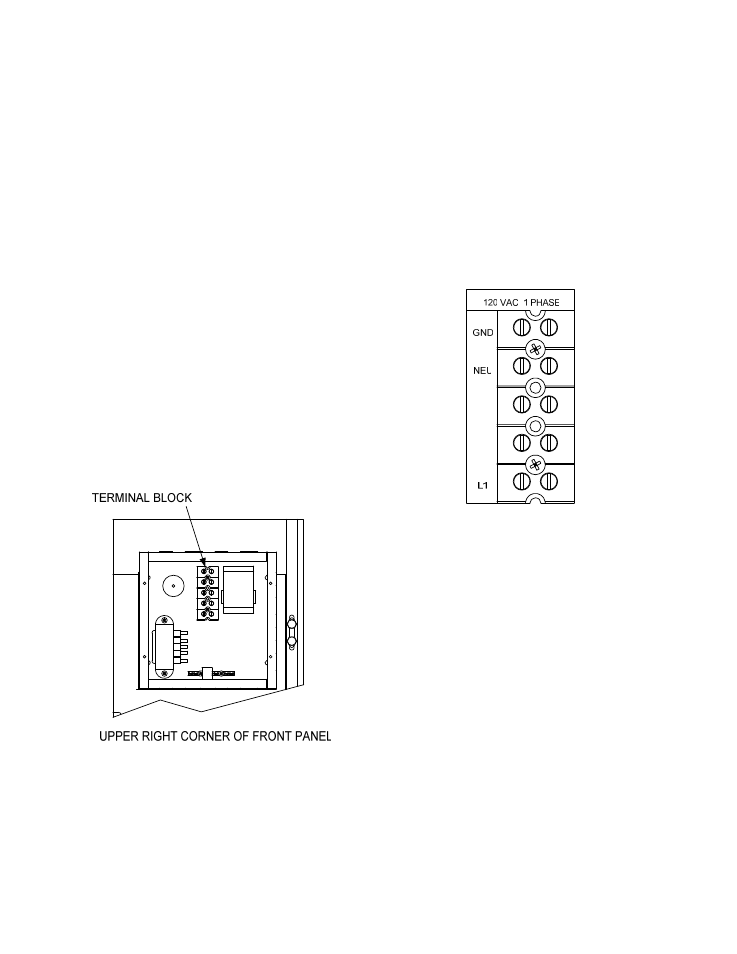

2.8 AC ELECTRICAL POWER WIRING

The AERCO Benchmark 2.0LN Electrical Power

Wiring Guide, GF-2060LN, must be consulted

prior to connecting any AC power wiring to the

unit. External AC power connections are made

to the unit inside the Power Box on the front

panel of the unit. Remove the front door of the

unit to access the Power Box mounted directly

above the Control Box. Loosen the four Power

Box cover screws and remove cover to access

the AC terminal connections inside the Power

Box (Figure 2-7).

NOTE

All electrical conduit and hardware must

be installed so that it does not interfere

with the removal of any unit covers, inhibit

service/maintenance, or prevent access

between the unit and walls or another

unit.

Figure 2-7

AC Input Terminal Block Location

2.8.1 Electrical Power Requirements

The AERCO Benchmark 2.0LN Boiler accepts

120 VAC, single-phase, 60 Hz @ 20A. The

Power Box contains a terminal block as shown

in Figure 2-8. In addition, a wiring diagram

Each Boiler must be connected to a dedicated

electrical circuit. NO OTHER DEVICE

showing the required AC power connections is

provided on the front cover of the Power Box.

S

l Power

SHOULD BE ON THE SAME ELECTRICAL

CIRCUIT AS THE BOILER. A means for

disconnecting AC power from the unit (such as a

service switch) must be installed near the unit

for normal operation and maintenance. All

electrical connections should be made in

accordance with the National Electrical Code

and/or with any applicable local codes.

For electrical power wiring diagrams, see the

AERCO Benchmark 2.0LN Electrica

Wiring Guide, (GF-2060LN).

Figure 2-8

AC Terminal Block Configurations

2.9

FIELD CONTROL WI

ble in

peration. While

loosen the four cover screws and

ing

MODES OF OPERATION AND

RING

The Benchmark 2.0LN Boiler is availa

several different modes of o

each unit is factory configured and wired for its

intended mode, some additional field wiring may

be required to complete the installation. This

wiring is typically connected to the Input/Output

(I/O) Box located on the lower portion of the unit

front panel (Figure 2-9) behind the removable

front door.

To access the I/O Box terminal strips shown in

Figure 2-10,

remove the cover. All field wiring is installed

from the rear of the panel by routing the wires

through one of the four bushings provided.

Refer to the wiring diagram provided on the

cover of the I/O Box (Figure 2-10) when mak

all wiring connections.