Chapter 3 control panel operating procedures, Control panel operating procedures – AERCO BMK 2.0 LN Nat. Gas for Mass. only User Manual

Page 23

CONTROL PANEL OPERATING PROCEDURES

3-1

CHAPTER 3 CONTROL PANEL OPERATING PROCEDURES

3.1 INTRODUCTION

The information in this Chapter provides a guide

to the operation of the Benchmark 2.0 Low NOx

Boiler using the Control Panel mounted on the

front of the unit. It is imperative that the initial

startup of this unit be performed by factory

trained personnel. Operation prior to initial

startup by factory trained personnel will void the

equipment warranty. In addition, the following

WARNINGS and CAUTIONS must be observed

at all times.

1

2

3

4

5

6

7

8

9

10

11

12

CAUTION

All of the installation procedures in

Chapter 2 must be completed before

attempting to start the unit.

WARNING

ELECTRICAL VOLTAGES IN THIS

SYSTEM MAY INCLUDE 460, 208

AND 24 VOLTS AC. IT MUST BE

SERVICED ONLY BY FACTORY

CERTIFIED SERVICE TECHNICIANS

WARNING

DO NOT ATTEMPT TO DRY FIRE

THE BOILER. STARTING THE UNIT

WITHOUT A FULL WATER LEVEL

CAN SERIOUSLY DAMAGE THE

UNIT AND MAY RESULT IN INJURY

TO PERSONNEL OR PROPERTY

DAMAGE. THIS SITUATION WILL

VOID ANY WARRANTY.

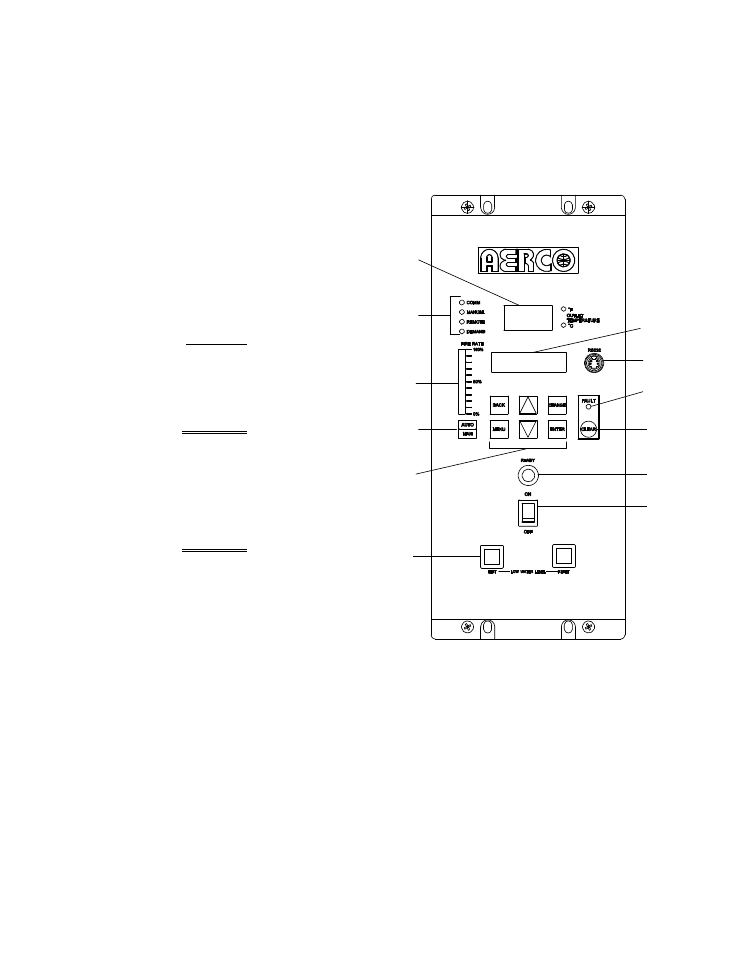

Figure 3-1.

Control Panel Front View

3.2 CONTROL PANEL DESCRIPTION

The Benchmark 2.0 Control Panel shown in

Figure 3-1 contains all of the controls, indicators

and displays necessary to operate, adjust and

troubleshoot the Benchmark 2.0 Boiler. These

operating controls, indicators and displays are

listed and described in Table 3-1. Additional

information on these items are provided in the

individual operating procedures provided in this

Chapter.