Checkline TI-CMX User Manual

Page 8

7. Repeat steps 5 & 6 until the known thickness value is correctly displayed.

8. Press the OK key to calculate the velocity and return to the menu screen,

or ESC to cancel the one point calibration.

9. Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

NOTE: CHECK YOUR CALIBRATION! Place the transducer back on the calibration

point. The thickness reading should now match the known thickness. If the thickness is

not correct, repeat the steps above.

2.5 Coating

Calibration

The TI-CMX has been preset to a default coating velocity of 0.0850 in/µsec (2159

m/sec). This will be very close to the most common coating material velocities used in

the field. If the velocity of the coating is known, and different than the above default set-

ting, the user can simply enter the coating velocity into the TI-CMX. However, if the

velocity is unknown, the TI-CMX can also be calibrated to a specific coating

sample/type using the 1pt calibration option in PECT (pulse-echo coating) mode, or a

two point calibration is CT (coating only) mode. For the purpose of this quick start sec-

tion only the 1pt option PECT (pulse-echo coating) mode will be covered. Refer to the

calibration section of the manual for a complete explanation on the coating calibration

options. The following steps below outline the necessary steps to either set the velocity

of the coating, or perform a one point calibration to calculate the coating velocity:

Known Coating Velocity

If the coating velocity is known, the user may wish to simply

enter the velocity number into the TI-CMX, rather than have the

TI-CMX calculate the velocity value using a known thickness on

a coating sample. The steps for entering the velocity are outlined

below:

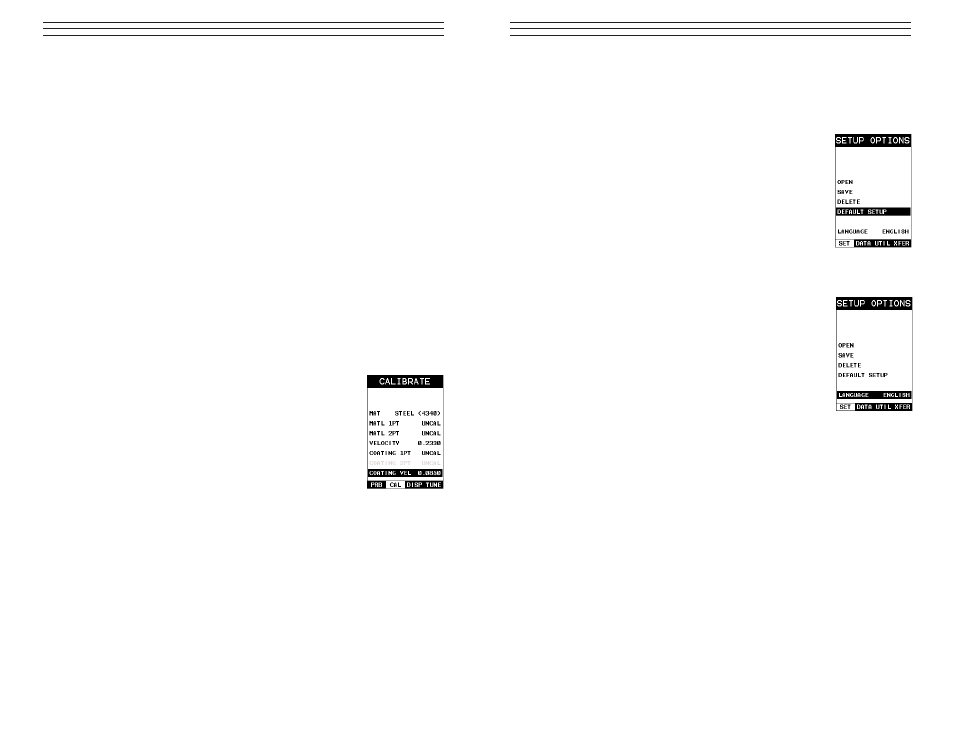

1. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right and the

ESC key multiple times to tab left until the CAL menu is

highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through the sub

menu items until COATING VEL is highlighted.

3. Press the ENTER key to display the Digits Edit Box.

4. Press the UP and DOWN arrow keys to scroll the highlighted value.

5. Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6. Repeat steps 4 & 5 until the velocity number is correctly displayed.

7. Press the OK key to set the coating velocity and return to the menu screen,

or ESC to cancel entering the coating velocity.

8. Finally, press the MEAS key to return to the measurement screen and begin taking

readings

-8-

11.5 Using the Default Setup

The default setup feature was added to the CMX to use, as a last resort, if there are no

setups stored in the gauge –factory or otherwise. The only time this might possibly

occur is if the setup file in the CMX was somehow corrupted, and the user does not have

access to a computer to re-load the factory setups back into the CMX. This gives the

user the ability to load and modify a basic setup as follows:

1. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right and the

ESC key multiple times to tab left until the SETUP menu

is highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through the

sub menu items until DEFAULT SETUP is highlighted.

11.6 Selecting a Language

The CMX is equipped with a language option. Currently, the

only languages supported are English, Spanish, and German.

The steps to select one of these languages are outlined as

follows:

1. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right and the

ESC key multiple times to tab left until the SETUP menu is

highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through the

sub menu items until LANGUAGE is highlighted.

3. Press the LEFT and RIGHT arrow keys to toggle the

language options.

4. Once the desired language is displayed, press the MEAS

key to return to the measurement screen.

-49-