Checkline TI-CMX User Manual

Page 15

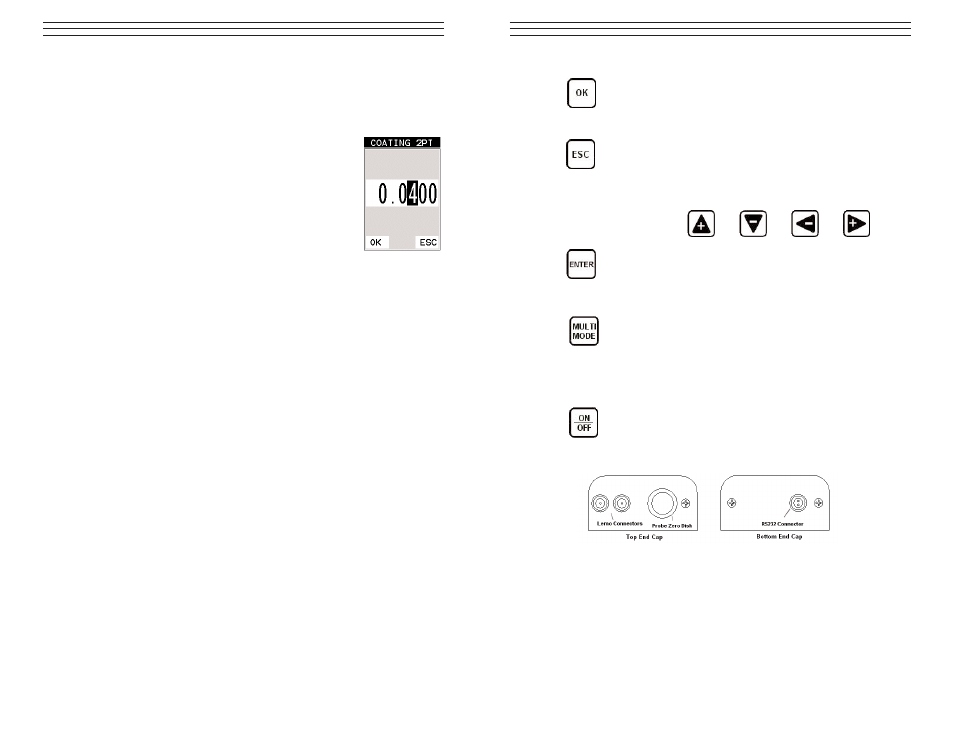

3.11 OK Key

The primary function of the OK key is confirmation of a change or selection.

3.12 ESC Key

The ESC key is used in the MENU, MEAS, and EDIT functions as a back or

escape function.

3.13 Arrow Keys

The Arrow Keys are used to navigate through the menus, increase/decrease values, and

toggle specific function keys.

3.14 ENTER key

The ENTER key is used in the menu navigation process to activate lists as

well as edit boxes.

3.15 MULTI MODE Key

The MULTI MODE key opens a measurement mode screen listing all the

modes that are available to the transducer specifically selected. The modes can

be all or a combination of the entire set of modes the TI-CMX offers, depend-

ing on which transducer is being used as follows: Coating Off (P-E), Coating

On (PECT), Temp Comp (PETP), Thru-Coat (E-E), and Coating Only (CT).

3.16 ON/OFF Key

The ON/OFF key simply powers the unit either ON or OFF. Note: Unit will

automatically power off when idle for 5 minutes. All current settings are

automatically saved prior to powering off.

3.17 Top & Bottom End Caps

The top & bottom end panels are where all connections are made to the TI-CMX. The

diagram above shows the layout and description of the connectors:

Transducer Connectors

Refer to Diagram: The transducer connectors, and battery cover/probe zero disk are

located on the TI-CMX’s top end cap. The transducer connectors are of type Lemo “00”.

NOTE: There is no polarity associated with connecting the transducer to the TI-CMX.

-15-

2. Apply a drop of couplant on the transducer and place the transducer in steady contact

with the thinner of the two coating and samples. Be sure that the reading is stable

and the repeatability indicator, in the top left corner of the display, is fully lit and

stable. Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until the

CAL menu is highlighted and displaying the submenu items.

3. Use the UP and DOWN arrow keys to scroll through the

sub menu items until COATING 2PT is highlighted.

4. Press the ENTER key to display the Digits Edit Box.

5. Press the UP and DOWN arrow keys to scroll the

highlighted value.

6. Press the LEFT and RIGHT arrow keys to scroll the digit

locations.

7. Repeat steps 5 & 6 until the known thickness value is

correctlydisplayed.

8. Press the OK key to calculate the velocity and return to the menu screen,

or ESC to cancel the coating one point calibration.

9. Finally, press the MEAS key to return to the measurement screen and begin taking

readings.

NOTE: CHECK YOUR CALIBRATION! Place the transducer back on both calibration

points. The coating thickness readings should now match the known thickness values of

each sample. If the thickness is not correct, repeat the steps above.

-42-