Checkline TI-CMX User Manual

Page 22

-22-

7.4 Gain

The gain, or amplification of the return echoes, can be adjusted in the TI-CMX to

accommodate a variety of applications. The setting of the gain is crucial in order to

obtain valid readings during the measurement process. Too much gain may result in

erroneous measurements, by detecting on noise rather than the actual material back wall

itself. Not enough gain may result in intermittent detection. It may also result in lack of

detection on internal flaws, pits, or porosity. The gain can easily be compared to the vol-

ume control of a home stereo system. If you turn it up too much, you can’t hear the

music clearly. If it’s turned down too much, you can’t hear it at all.

The TI-CMX has five gain settings (VLOW, LOW, MED, HI, VHI). The gain range is

42dB – 50dB in 2dB increments. Note: The TI-CMX has been optimized for the MED

gain setting for all common applications. It should be operated in this mode as standard.

However, some applications may require the lower or higher gain settings. When? The

low settings may be necessary for noisy or granular cast materials. How do I know when

to lower the gain? If the reading becomes sporadic and won’t settle down or resolve on a

thickness value, the user can assume that the material is either very noisy aluminum, or

granular cast iron. This would be a good time to change the TI-CMX to lower gain set-

ting and see if the reading settles down and become stable.

How do I know when to increase the gain? Often times the user will be trying to meas-

ure a material that is hard to penetrate or pass sound through. This may be due to the

material type, or overall thickness of the material. When a material is hard to pass sound

through because of the thickness or general make-up, it would be a good time to consid-

er switching the TI-CMX into a higher gain setting. Another example might be the need

to increase overall sensitivity for locating fine pits or flaws. In any case, the selectable

gain settings offer the user some additional options to resolve and overcome application

issues.

Note: When the echo-echo thru-paint measurement mode is selected, the manual gain

feature is disabled and grayed out in the menu items. In this mode, the TI-CMX switch-

es to an automatic gain mode (AGC) that optimizes the gain setting automatically in the

hardware of the TI-CMX.

The procedures to adjust the Gain are outlined below:

1. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right, and the

ESC key multiple times to tab left, until the TUNE menu is

highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through the sub

menu items until GAIN is highlighted.

3. Press the LEFT and RIGHT arrow keys to scroll the value.

When the correct Gain is being displayed, press the MEAS

key to return to the measurement screen and begin taking

readings.

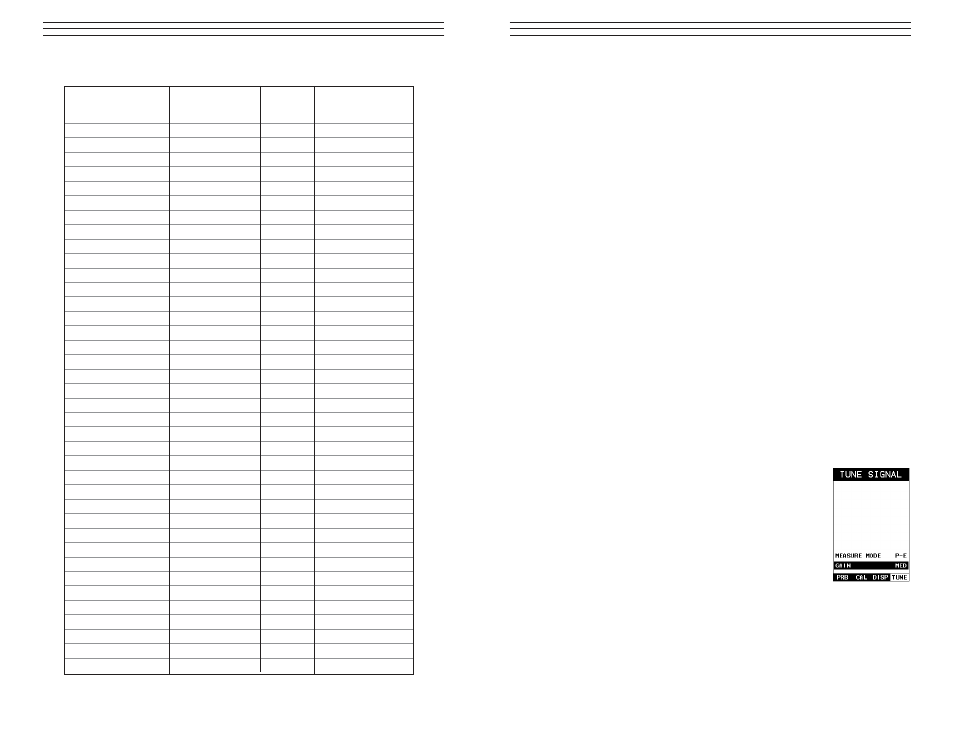

-35-

Material

sound velocity

sound velocity

in/us

m/s

Aluminum

0.2510

6375

Beryllium

0.5080

12903

Brass

0.1730

4394

Bronze

0.1390

3531

Cadmium

0.1090

2769

Columbium

0.1940

4928

Copper

0.1830

4648

Glass (plate)

0.2270

5766

Glycerine

0.0760

1930

Gold

0.1280

3251

Inconel

0.2290

5817

Iron

0.2320

5893

Cast Iron

0.1800

(approx)

4572

Lead

0.0850

2159

Magnesium

0.2300

5842

Mercury

0.0570

1448

Molybdenum

0.2460

6248

Monel

0.2110

5359

Nickel

0.2220

5639

Nylon

0.1060

(approx)

2692

Platinum

0.1560

3962

Plexiglas

0.1060

2692

Polystyrene

0.0920

2337

PVC

0.0940

2388

Quartz glass

0.2260

5740

Rubber vulcanized

0.0910

2311

Silver

0.1420

3607

Steel (1020)

0.2320

5893

Steel (4340)

0.2330

5918

Steel Stainless"

0.2230

5664

Teflon

0.0540

1372

Tin

0.1310

3327

Titanium

0.2400

6096

Tungsten

0.2040

5182

Uranium

0.1330

3378

Water

0.0580

1473

Zinc

0.1660

4216

Zirconium

0.1830

4648

Acoustic Velocity Table