Checkline TI-CMX User Manual

Page 23

6.0 T

AKING

M

EASUREMENTS

The steps involved in making measurements are detailed in this section. The following sections

outline how to setup and prepare your TI-CMX for field use.

An automatic or manual zero must always be performed. The auto zero is an off block elec-

tronic zero that does not require a zero reference block. This will most always be the zero

option of choice, as it makes the zeroing process very easy and convenient to perform.

However, If the manual zero option is enabled, the probe zero must be measured on the refer-

ence disk (battery disk) attached to the top of the instrument. The zero compensates for varia-

tions in the transducer. In all modes the sound velocity must be determined. The sound velocity

is used to convert the transit time to a physical length. The sound velocity can be selected from

a material chart in the manual, selected from a material list in the TI-CMX, or for greater pre-

cision determined from a sample of the test material that has been mechanically measured. To

enter the velocity from a table, look up the material on the chart in the appendix of this manual

and refer to the section below on Calibration to a Known Velocity. To determine the velocity of

a single sample, refer to the Material Calibration section 6.0

When measuring curved materials, it is more accurate to calibrate from two test points, one at

the minimum limit of the target thickness and one at the maximum limit. In this case the refer-

ence disk mounted to the TI-CMX is not used. This is called two-point calibration and is

described on section 6.0.

6.1 Auto Probe Recognition & Selecting The Transducer Type

The first step in using the TI-CMX is to plug the transducer into the gauge and power

the unit up. The TI-CMX has a special built-in automatic probe recognition feature that

will check to see if the probe plugged into the gauge is an auto recognized probe type. If

so, the TI-CMX will display a message indicating the transducer type and ask the user

for confirmation to use the identified probe. If the transducer is not an auto recognized

probe, the TI-CMX will display a message indicating the transducer type has not been

recognized, and force the user to select a transducer type from a list of transducers

according to frequency and diameter. Whether the transducer is auto recognized or

selected from a predefined list, the TI-CMX will recall specific properties about the

transducer.

NOTE: Once the transducer has been selected, the TI-CMX will store and recall this

transducer type every time the TI-CMX is powered on/off. The type will only change if

the user physically selects another type from the list, or selects a previously saved setup.

Therefore, if you have previously gone through this section and selected the transducer

you are using, proceed to the next section. Use the following steps to select your trans-

ducer type.

NOTE: If the transducer is not identified on power up, be sure the

transducer type Selected is the same as the transducer plugged

into the TI-CMX. Failure to do this will result in erroneous meas-

urements:

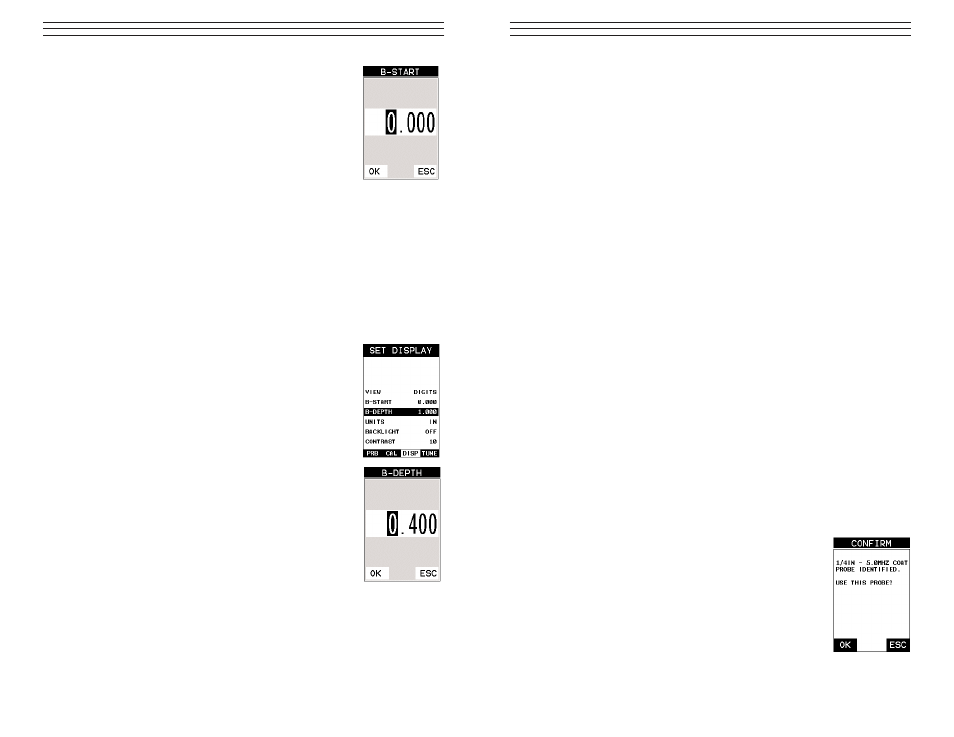

In this first example the transducer was automatically identified:

1. Press the OK key once to use the identified probe, or ESC

to display a list of optional transducers.

NOTE: If the TI-CMX recognizes a specific transducer, the user

should always select OK to use the identified probe. The only time an alternative probe

should be selected from a list is if the user switched probes following initial power up

and recognition, or the TI-CMX has somehow identified the probe in error..

-23-

4. Alternatively, press the ENTER key to display the Digits

Edit Box.

5. Press the UP and DOWN arrow keys to scroll the

highlighted value.

6. Press the LEFT and RIGHT arrow keys to scroll the digit

locations.

7. Repeat steps 5 & 6 until the B-Start value is correctly

displayed.

8. Press the OK key to set the B-Start value and return to the

menu screen, or ESC to cancel entering the B-Start.

9. Finally, press the MEAS key to return to the measurement screen and begin taking

readings.

Overall range (B-DEPTH)

Once again, just to reiterate, B-DEPTH is the overall viewable thickness range being

tested. This should be set to a value slightly larger then the expected maximum range

being measured. The procedures to adjust the overall thickness range viewed (B-

DEPTH) are outlined below:

Adjusting the Overall Depth (B-DEPTH)

1. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right, and the

ESC key multiple times to tab left, until the DISP menu is

highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through the

sub menu items until B-DEPTH is highlighted.

3. Press the LEFT and RIGHT arrow keys to scroll the value.

When the correct width is being displayed, proceed to

step 8.

4. Alternatively, press the ENTER key to display the Digits

Edit Box.

5. Press the UP and DOWN arrow keys to scroll the

highlighted value.

6. Press the LEFT and RIGHT arrow keys to scroll the digit

locations.

7. Repeat steps 5 & 6 until the B-Scan Depth value is correctly

displayed.

8. Press the OK key to set the B-SCAN Depth and return to

the menu screen, or ESC to cancel entering the B-Depth.

9. Finally, press the MEAS key to return to the measurement screen

and begin taking readings.

-34-