Checkline TI-CMX User Manual

Page 6

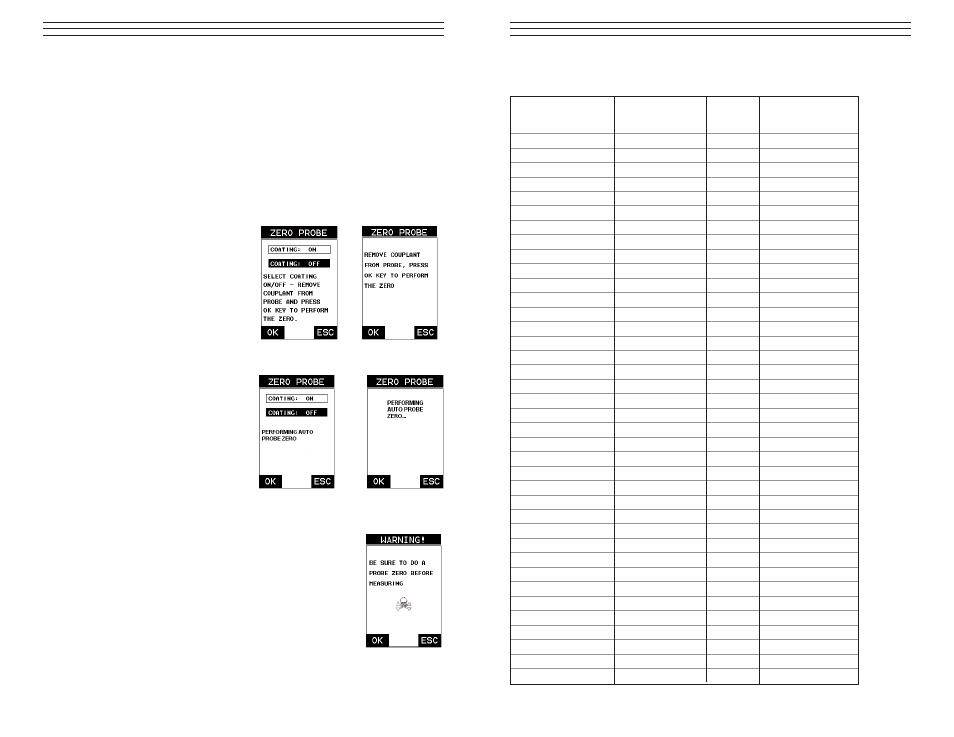

2.4 Probe Zero & One Point Calibration

The next steps are to perform a probe zero and calibrate the TI-CMX to the material and

transducer being used. If the sound velocity is unknown, the TI-CMX can be calibrated

to a known thickness sample. This demo will briefly explain both of these techniques.

The TI-CMX is equipped with two zero options:

• Off Block Zero (Automatic Probe Zero) – When this feature is enabled the TI-

CMX will do an electronic zero automatically, eliminating the need for a zero disk or

block.

• On Block Zero (Manual Probe Zero) – When this feature is enabled the transducer

must be placed on the probe zero disk (battery cover located on the top of the unit.

Both zero procedures are outlined as

follows:

Off Block Zero (Automatic Probe

Zero)

1. Be sure all couplant has been

removed from the face of the

transducer.

2. Press the OK key to perform the

automatic probe zero, or ESC key

to cancel the zero operation.

3. The screens illustrated at the right

will be briefly displayed followed

by the main measurement screen.

The TI-CMX is ready to be

calibrated.

-6-

Coating Probe

Identified

Coating Probe

Not Identified

Coating Probe

Identified

Coating Probe

Not Identified

Performing a Manual Probe Zero (On Block)

NOTE: When the zero probe option is set to manual, the probe

zero disk (battery cap) located on the top of the gauge, will be

used as a zero standard and the warning screen illustrated above

will be displayed.

1. Press the OK or ESC keys to enter the main measurement

screen and begin the manual zero process.

2. Apply a drop of couplant on the transducer and place the

transducer in steady contact with the probe zero disk, and

obtain a steady reading.

A

PPENDIX

A: V

ELOCITY

T

ABLE

-51-

Material

sound velocity

sound velocity

in/us

m/s

Aluminum

0.2510

6375

Beryllium

0.5080

12903

Brass

0.1730

4394

Bronze

0.1390

3531

Cadmium

0.1090

2769

Columbium

0.1940

4928

Copper

0.1830

4648

Glass (plate)

0.2270

5766

Glycerine

0.0760

1930

Gold

0.1280

3251

Inconel

0.2290

5817

Iron

0.2320

5893

Cast Iron

0.1800

(approx)

4572

Lead

0.0850

2159

Magnesium

0.2300

5842

Mercury

0.0570

1448

Molybdenum

0.2460

6248

Monel

0.2110

5359

Nickel

0.2220

5639

Nylon

0.1060

(approx)

2692

Platinum

0.1560

3962

Plexiglas

0.1060

2692

Polystyrene

0.0920

2337

PVC

0.0940

2388

Quartz glass

0.2260

5740

Rubber vulcanized

0.0910

2311

Silver

0.1420

3607

Steel (1020)

0.2320

5893

Steel (4340)

0.2330

5918

Steel Stainless"

0.2230

5664

Teflon

0.0540

1372

Tin

0.1310

3327

Titanium

0.2400

6096

Tungsten

0.2040

5182

Uranium

0.1330

3378

Water

0.0580

1473

Zinc

0.1660

4216

Zirconium

0.1830

4648