Carrier 38AH044-084 User Manual

Page 48

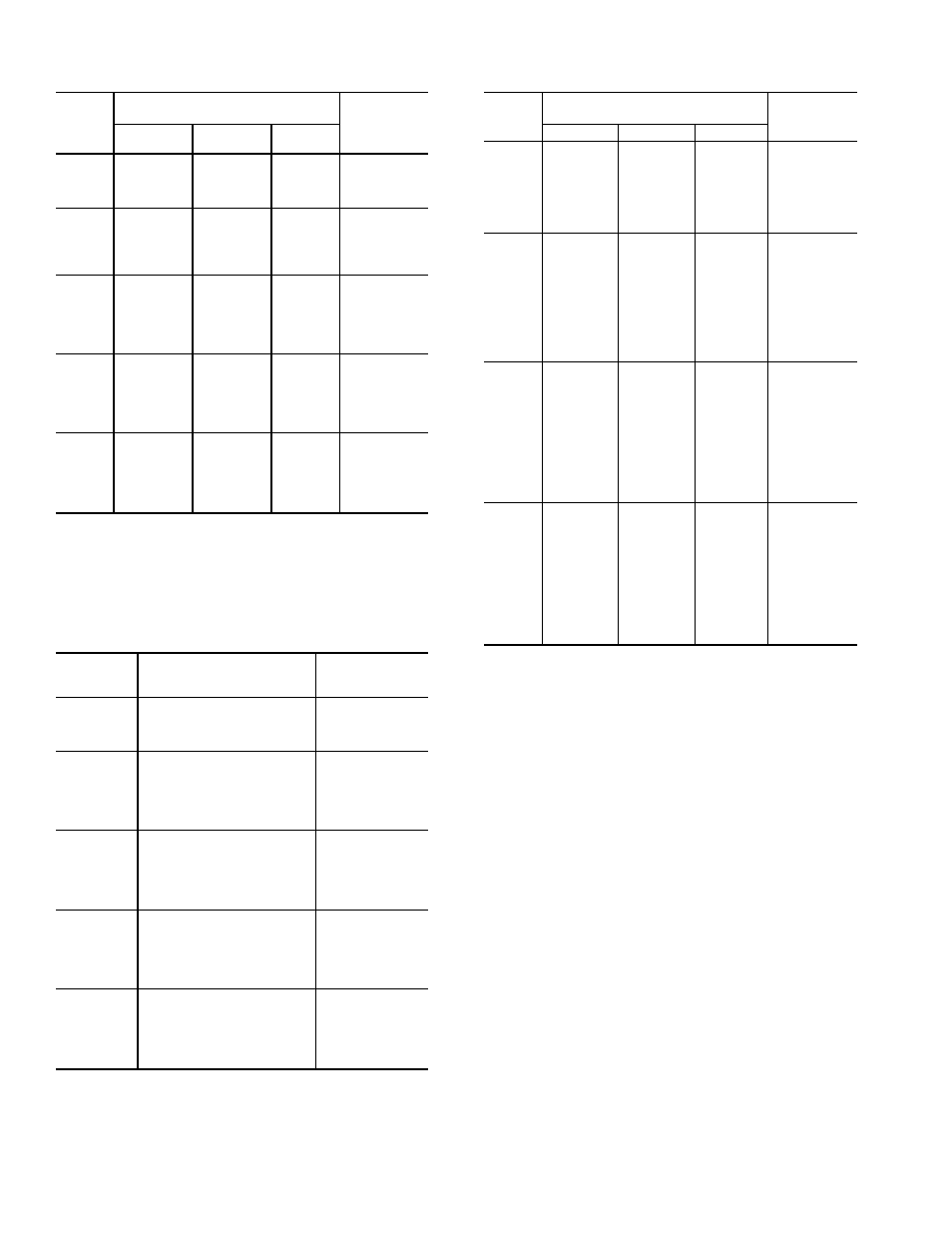

Table 19A — One 2-Stage Thermostat Capacity

Control for 38AH044-084 Dual-Circuit Units

UNIT

38AH

QUANTITY OF LOADED

COMPRESSOR CYLINDERS

SYSTEM

CAPACITY

(%)

Circuit

A

Circuit

B

Total

044

4

4

8

100

2

4

6

75

4

0

4

50

2

0

2

25

054

4

6

10

100

2

6

8

79

2

4

6*

59

4

0

4

42

2

0

2

21

064

6

6

12

100

4

6

10

84

2

6

8*

68

6

0

6

48

4

0

4

32

2

0

2*

16

074

6

6

12

100

4

6

10

86

2

6

8*

72

6

0

6

43

4

0

4

29

2

0

2*

15

084

6

6

12

100

4

6

10

83

2

6

8*

66

6

0

6

50

4

0

4

33

2

0

2*

17

*Requires units with VAV (variable air volume) factory-supplied

option.

NOTE: Units have 2 independent refrigeration circuits. Circuit A is lead

circuit.

Table 19B — One 2-Stage Thermostat Capacity

Control for 38AH044-084 Optional Single-Circuit Units

UNIT

38AH

QUANTITY OF

LOADED CYLINDERS

SYSTEM

CAPACITY

(%)

044

8

100

6

75

4

50

2

25

054

10

100

8

81

6

60

6

56

4

37

2*

19*

064

12

100

10

82

8

64

6

56

4

36

2†

18

074

12

100

10

81

8

62

6

57

4

38

2†

19

084

12

100

10

83

8

66

6

50

4

33

2†

17

*Requires accessory unloader on lead 06E-265 compressor (A1).

†Requires VAV (variable air volume) factory-installed option or ac-

cessory unloader.

Table 20 — One 2-Stage Thermostat Capacity

Control for 38AH094-134 Units

UNIT

38AH

QUANTITY OF LOADED

COMPRESSOR CYLINDERS

SYSTEM

CAPACITY

(%)

Ckt A

Ckt B

Total

10

6

16

100

10

4

14

85

10

2

12

70*

10

0

10

55

094

8

0

8

44

6

0

6

33

4

0

4

22

104

10

12

22

100

8

12

20

91

8

10

18

82

10

6

16

73

6

6

12

55

6

4

10

45

0

6

6

27

4

0

4

18

0

4

4

18

2†

0

2

9†

124

12

12

24

100

10

12

22

92

10

10

20

83

8*

10

18

75*

6

10

16

67

6

8*

14

58*

6

6

12

50

4

6

10

42

6

0

6

25

4

0

4

17

2*

0

2

8*

134

12

12

24

100

10

12

22

92

10

10

20

83

8*

10

18

75*

6

10

16

67

6

8*

14

58*

6

6

12

50

4

6

10

42

6

0

6

25

4

0

4

17

2*

0

2

8*

*Requires VAV (variable air volume) unit or accessory unloader(s) field

installed on circuit lead compressor. Lead compressor is identified in

Table 16, page 40.

†Requires field-installed accessory unloader on circuit lead compres-

sor. Lead compressor is identified in Table 16, page 40.

NOTES:

1. Temperatures calculated with the minimum number of fans oper-

ating per circuit.

2. See Table 16, page 40, for information on lead and lag circuits.

CONTROL SET POINT — Control set point (cylinder load

point) is adjustable from 0 to 85 psig (0 to 586 kPag).

To adjust the set point, turn the control set point adjust-

ment nut clockwise to bottom stop. (See Fig. 46.) In this

position, load-up set point is 85 psig (586 kPag). Turn

adjustment counterclockwise to desired control set point.

Every full turn clockwise decreases the load-up set point by

7.5 psig (52 kPag).

PRESSURE DIFFERENTIAL — Pressure differential

(difference between cylinder load and unload points) is

adjustable from 6 to 22 psig (41 to 152 kPag). To adjust,

turn pressure differential adjustment screw counterclock-

wise to back stop position. The differential pressure is now

adjusted to 6 psig (41 kPag). Turn the adjustment screw clock-

wise to adjust the differential pressure. Every full clockwise

turn increases the differential by 1.5 psig (10 kPag).

48