Carrier 38AH044-084 User Manual

Page 16

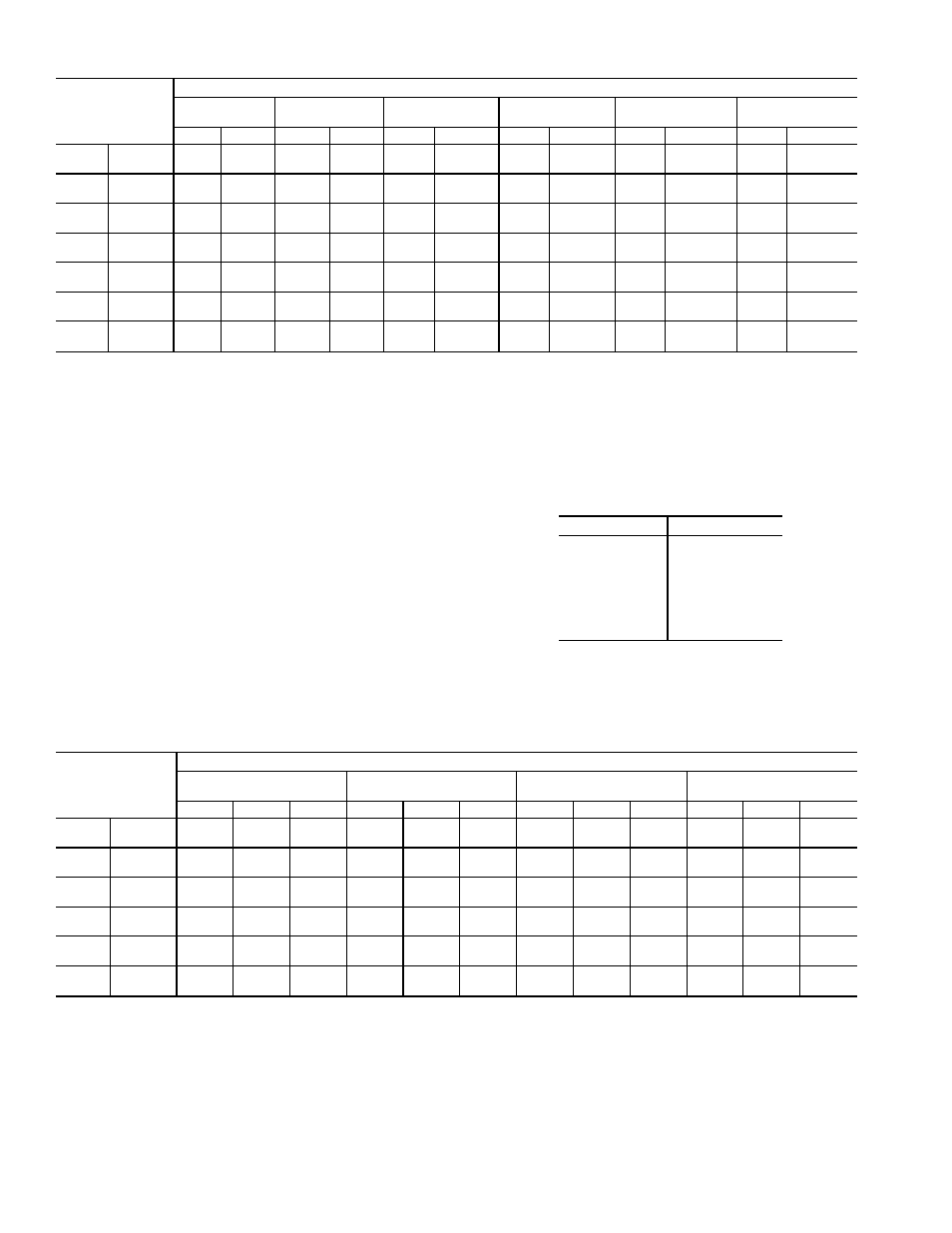

Table 6A — Refrigerant Piping Requirements — 38AH044-104 Dual-Circuit Units — 60 Hz

UNIT

38AH

TOTAL LINEAR LENGTH OF INTERCONNECTING PIPE — FT (M)

15-25

(4.6-7.6)

25-50

(7.6-15.2)

50-75

(15.2-22.9)

75-100

(22.9-30.5)

100-150

(30.5-45.7)

150-200

(45.7-61.0)

L

S

L

S

L

S

L

S

L

S

L

S

044

Ckt A

5

⁄

8

1

5

⁄

8

7

⁄

8

1

5

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

Ckt B

5

⁄

8

1

5

⁄

8

7

⁄

8

1

5

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

054

Ckt A

5

⁄

8

1

5

⁄

8

7

⁄

8

1

5

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

Ckt B

7

⁄

8

1

5

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

*

064

Ckt A

7

⁄

8

1

5

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

†

Ckt B

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

1

1

⁄

8

2

5

⁄

8

074

Ckt A

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

†

1

1

⁄

8

2

5

⁄

8

†

Ckt B

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

1

3

⁄

8

2

5

⁄

8

1

3

⁄

8

2

5

⁄

8

084

Ckt A

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

†

1

3

⁄

8

2

5

⁄

8

†

1

3

⁄

8

2

5

⁄

8

†

Ckt B

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

1

3

⁄

8

2

5

⁄

8

1

3

⁄

8

2

5

⁄

8

094

Ckt A

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

†

1

1

⁄

8

2

5

⁄

8

†

1

3

⁄

8

2

5

⁄

8

†

1

3

⁄

8

3

1

⁄

8

**

Ckt B

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

1

1

⁄

8

2

5

⁄

8

1

3

⁄

8

2

5

⁄

8

104

Ckt A

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

†

1

1

⁄

8

2

5

⁄

8

†

1

3

⁄

8

2

5

⁄

8

†

1

3

⁄

8

3

1

⁄

8

**

Ckt B

7

⁄

8

2

1

⁄

8

1

1

⁄

8

2

1

⁄

8

1

1

⁄

8

2

5

⁄

8

1

1

⁄

8

2

5

⁄

8

1

3

⁄

8

3

1

⁄

8

**

1

3

⁄

8

3

1

⁄

8

**

LEGEND

L — Liquid Line

S — Suction Line

*Double suction riser required on units with field installed unloader

on circuit B compressor if condensing unit is elevated above

evaporator.

†Double suction riser required on units with field installed unloader

on circuit B compressor if condensing unit is elevated above

evaporator.

**Double suction riser required on all unit configurations if condens-

ing unit is elevated above evaporator.

NOTES:

1. Addition of 2 unloaders to circuit B compressor is not

recommended.

2. 38AH094 and 38AH104 piping sizes apply only to factory sup-

plied unit configurations. They do NOT take into account any field

installed unloaders.

3. Piping sizes are based on unit operation above 40 F (4.4 C) satu-

rated suction temperature (SST). When operating below 40 F

(4.4 C), refer to Carrier System Design Manual, E20-II

ா

piping de-

sign program, or ASHRAE Handbook to select proper line sizes.

4. Pipe sizes are based on the total linear length shown for each

column, plus a 50% allowance for fittings.

5. Suction and liquid line sizing is based on pressure drop equivalent

to 2 F (1.1 C) at nominal rating conditions. Higher pressure drop

design criteria may allow selection of smaller pipe sizes, but at a

penalty of decreased system capacity and efficiency.

6. Double suction risers may be required if condensing unit is

elevated above the evaporator. See footnotes and double suction

riser table below.

7. Refer to Carrier System Design Manual or to E20-II design

programs for further information on selecting pipe sizes for split

systems.

8. All pipe sizes are OD inches. Equivalent sizes in millimeters

follow:

in.

mm

5

⁄

8

15.9

7

⁄

8

22.2

1

1

⁄

8

28.6

1

3

⁄

8

34.9

1

5

⁄

8

41.3

2

1

⁄

8

54.0

2

5

⁄

8

66.7

3

1

⁄

8

79.4

Table 6B — Refrigerant Piping Requirements for Double Suction Risers,

38AH054-104 Dual-Circuit Units — 60 Hz

UNIT

38AH

TOTAL LINEAR LENGTH OF INTERCONNECTING PIPE — FT (M)

50-75

(15.2-22.9)

75-100

(22.9-30.5)

100-150

(30.5-45.7)

150-200

(45.7-61.0)

A

B

C

A

B

C

A

B

C

A

B

C

054

Ckt A

—

—

—

—

—

—

—

—

—

—

—

—

Ckt B

—

—

—

—

—

—

—

—

—

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

064

Ckt A

—

—

—

—

—

—

—

—

—

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

Ckt B

—

—

—

—

—

—

—

—

—

—

—

—

074

Ckt A

—

—

—

—

—

—

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

Ckt B

—

—

—

—

—

—

—

—

—

—

—

—

084

Ckt A

—

—

—

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

Ckt B

—

—

—

—

—

—

—

—

—

—

—

—

094

Ckt A

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

1

5

⁄

8

2

1

⁄

8

2

5

⁄

8

1

5

⁄

8

2

5

⁄

8

3

1

⁄

8

Ckt B

—

—

—

—

—

—

—

—

—

—

—

—

104

Ckt A

1

3

⁄

8

2

1

⁄

8

2

5

⁄

8

1

3

⁄

8

2

1

⁄

8

2

5

⁄

8

1

3

⁄

8

2

1

⁄

8

2

5

⁄

8

1

5

⁄

8

2

5

⁄

8

3

1

⁄

8

Ckt B

—

—

—

—

—

—

1

3

⁄

8

2

5

⁄

8

3

1

⁄

8

1

5

⁄

8

2

5

⁄

8

3

1

⁄

8

LEGEND

—

— Not Required

Pipe A — Suction Riser Without Trap

Pipe B — Suction Riser With Trap

Pipe C — Suction Line to Condensing Unit

NOTES:

1. See Refrigerant Piping Requirements table at top of page to

determine need for double suction risers.

2. Pipe sizes are based on the total linear length, shown for each

column, plus a 50% allowance for fittings.

3. Suction and liquid line sizing is based on pressure drop equivalent

to 2 F (1.1 C) at nominal rating conditions. Higher design pressure

drop criteria may allow selection of smaller pipe sizes but at a pen-

alty of decreased system capacity and efficiency.

4. Refer to Carrier System Design Manual or to E20-II design

programs for further information on selecting pipe sizes for split

systems.

5. All pipe sizes are OD inches. See Table 6A notes for metric

equivalents.

6. Refer to Fig. 13 for double suction riser construction.

16