Step 2 — check compressor mounting – Carrier 38AH044-084 User Manual

Page 3

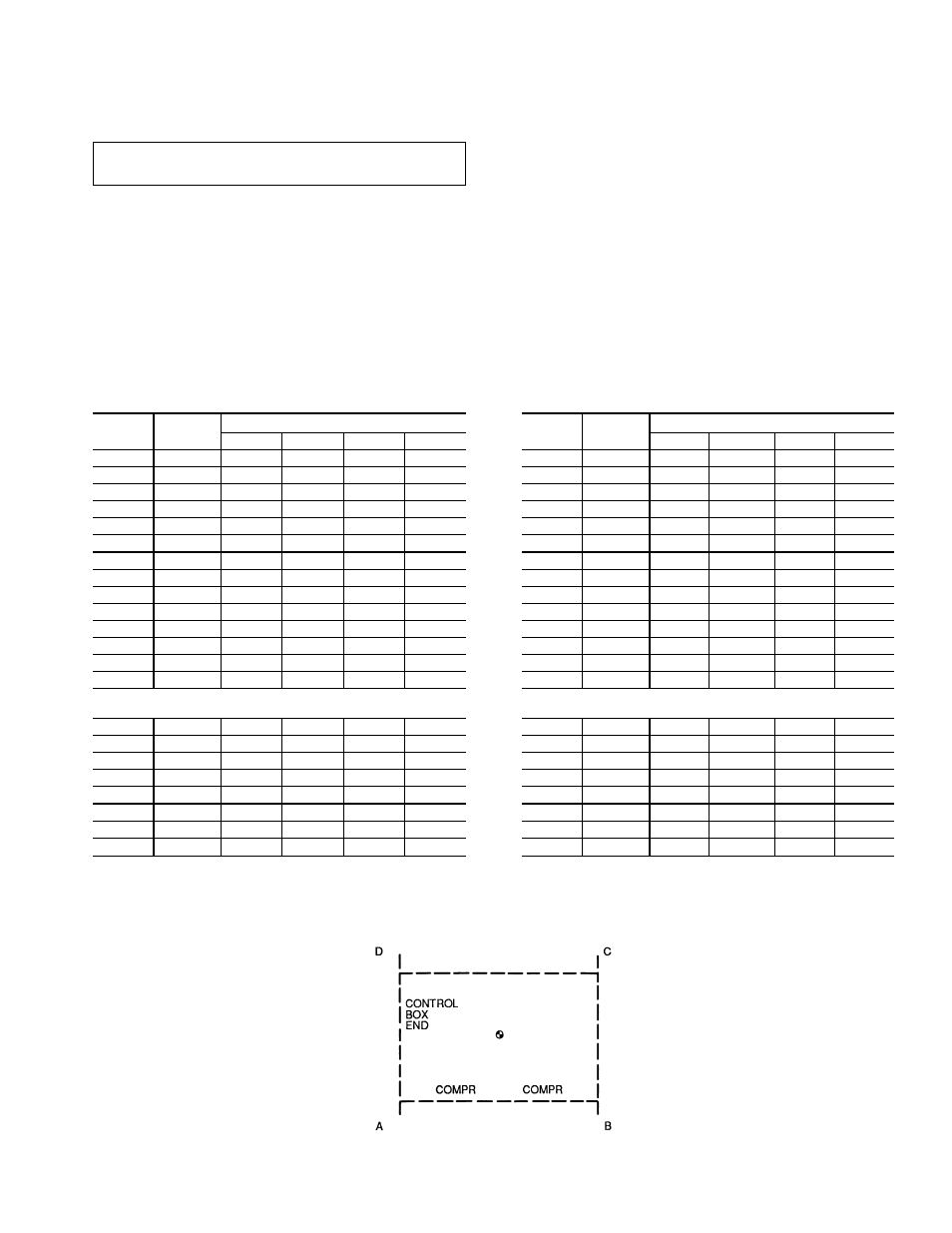

Remove sheet metal cover panels from return-bend end of

Module 124B or 134B. Place Module 124B or 134B in

position. The exposed return-bend ends of each module are

now opposite each other and facing the service space. The

compressors of each module are on opposite sides of the unit.

IMPORTANT: Modules must be placed 24 in.

(610 mm) apart and square relative to each other.

The modules are now in position for piping installa-

tion and final assembly. See Fig. 8. For mounting units on

vibration isolators, a perimeter support channel is required

between the assembled unit and the support isolators. The

perimeter support channel must be sized to support the fully

assembled unit. Do not support modules on individual iso-

lation supports. Support channel, hardware, and fasteners are

field supplied.

When unit is in proper location, level unit and bolt into

position with field-supplied bolts.

Step 2 — Check Compressor Mounting

UNITS 38AH044-084 — Compressors are mounted on pans

and are held down by 4 bolts during shipment. After unit is

installed, loosen each of these bolts until the snubber washer

can be moved with finger pressure. See Fig. 10.

UNITS 38AH094-134 — Units 38AH094 and 104 compres-

sors are mounted on rails and held down by rail bolts during

shipment. After unit is installed, loosen the rail bolts to al-

low the rails and compressors to float freely on the springs

located under the rails. See Fig. 10.

Units 38AH124 and 134 compressors are mounted on pans

and are held down by 4 bolts during shipment. After unit is

installed, loosen each of these bolts until snubber washer can

be moved with finger pressure. See Fig. 10.

Table 2A — Operational Corner Weights with

Refrigerant Charge (Approximate) — Lb

UNIT

38AH

TOTAL

WEIGHT

OPERATIONAL CORNER WEIGHT

A

B

C

D

044

3259

939

893

695

732

044C

3547

1013

967

765

802

054

3309

964

905

697

742

054C

3597

1034

978

771

814

064

3565

1018

1011

765

771

064C

3998

1125

1117

874

879

074

3812

1146

986

777

903

074C

4229

1272

1059

862

1035

084

4057

1220

1049

827

961

084C

4735

1425

1186

965

1159

094

5088

1114

2192

1182

601

094C

5813

1273

2504

1350

686

104

5435

1240

2138

1302

755

104C

6160

1405

2423

1476

856

MODULE

38AH

124A

3630

1037

1030

779

785

124A-C

4063

1144

1137

889

894

124B

3630

1037

1030

779

785

124B-C

4063

1144

1137

889

894

134A

3630

1037

1030

779

785

134A-C

4063

1144

1137

889

894

134B

3877

1167

997

789

924

134B-C

4294

1293

1080

874

1047

LEGEND

C — Copper Fin Coils

NOTE: Total weight may differ from summation of corner weights due

to rounding of numerals.

Table 2B — Operational Corner Weights with

Refrigerant Charge (Approximate) — Kg

UNIT

38AH

TOTAL

WEIGHT

OPERATIONAL CORNER WEIGHT

A

B

C

D

044

1478

426

405

316

332

044C

1609

460

438

347

364

054

1501

437

411

316

337

054C

1632

469

444

350

369

064

1617

462

459

347

350

064C

1813

510

508

397

399

074

1729

520

447

352

410

074C

1918

577

481

391

470

084

1840

553

476

375

436

084C

2148

646

538

438

526

094

2308

505

994

536

272

094C

2637

577

1136

612

311

104

2465

562

970

591

342

104C

2794

637

1099

670

388

MODULE

38AH

124A

1647

470

467

353

356

124A-C

1843

519

516

403

405

124B

1647

470

467

353

356

124B-C

1843

519

516

403

405

134A

1647

470

467

353

356

134A-C

1843

519

516

403

405

134B

1759

529

452

358

419

134B-C

1948

587

490

396

475

LEGEND

C — Copper Fin Coils

NOTE: Total weight may differ from summation of corner weights due

to rounding of numerals.

TOP VIEW, TYPICAL

3