Start-up, Preliminary checks, Preliminary oil charge – Carrier 38AH044-084 User Manual

Page 38

START-UP

Compressor crankcase heaters must be on for 24 hours

before start-up. To energize the crankcase heaters, set the

space thermostat above the ambient so there will be no de-

mand for cooling. Close the field disconnect and turn on the

fan circuit breakers. Leave the compressor circuit breakers

off/open. The crankcase heaters are now energized.

Preliminary Checks

1. Ensure that compressor service valves are backseated.

2. Verify that each compressor on units 38AH044-084, 124,

and 134 floats freely on its mounting springs. Verify that

each compressor on units 38AH094 and 104 floats freely

on its rails.

3. Check that electric power supply agrees with unit name-

plate data.

4. Verify that compressor crankcase heaters are securely in

place.

5. Check that compressor crankcase heaters have been on at

least 24 hours.

6. Note that compressor oil level is visible in the sight glass.

7. Recheck for leaks using same procedure as previously out-

lined in Step 3 — Make Refrigerant Piping Connections,

page 14.

8. If any leaks are detected, evacuate and dehydrate as pre-

viously outlined in Step 3 — Make Refrigerant Piping

Connections, page 14.

Preliminary Oil Charge —

Each compressor is fac-

tory charged with oil (see Table 3A, 3B, 4A, or 4B). When

oil is checked at start-up, it may be necessary to add or re-

move oil to bring it to the proper level. One recommended

oil level adjustment method is as follows:

ADD OIL — Close suction shutoff valve and pump down

crankcase to 2 psig (14 kPa). (Low-pressure cutout must be

jumped.) Wait a few minutes and repeat until pressure re-

mains steady at 2 psig (14 kPa). Remove oil fill plug above

the oil level sight glass, add oil through plug hole, and re-

place plug. Run compressor for 20 minutes and check oil

level.

IMPORTANT: For units with 2 compressors per re-

frigeration circuit, both compressors must be running

to adjust the oil level. Two oil level equalizer lines

between compressors distribute the oil to each

compressor.

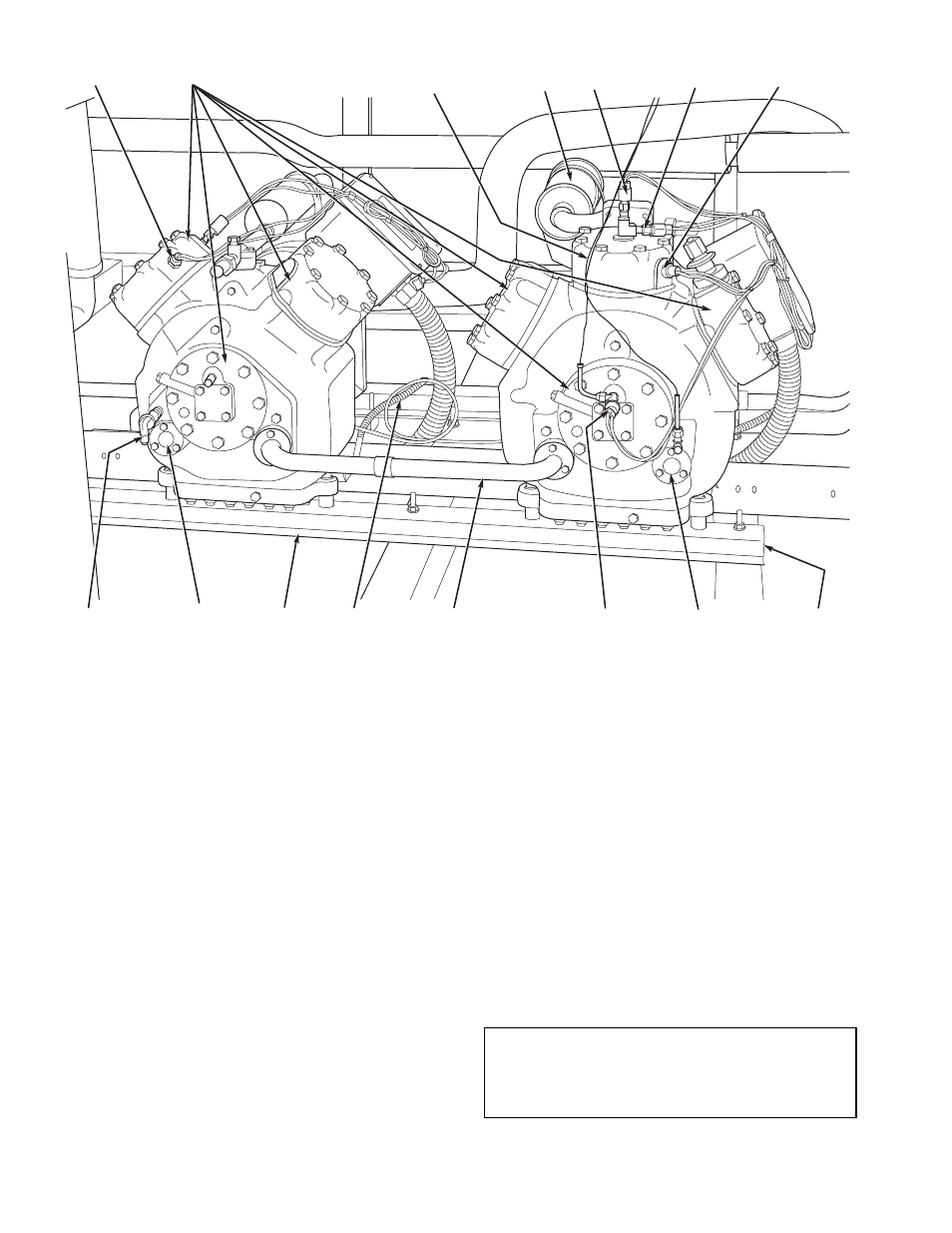

DISCHARGE

GAS THERMOSTAT

CYLINDER

HEADS

OIL PRESSURE SWITCH AND

CAPACITY CONTROL

PRESSURE SWITCH CAPILLARIES

MUFFLER

HIGH-

PRESSURE

SWITCH

FAN CYCLING

PRESSURE SWITCH

DISCHARGE GAS

THERMOSTAT

MOUNTING

SPRING

(HIDDEN)

SIGHT

GLASS

LOW-

PRESSURE

SWITCH

OIL

EQUALIZER

LINE

CRANKCASE

HEATER

RAIL

SIGHT

GLASS

PRESSURE RELIEF

VALVE

NOTE: Units 38AH044-084 and 38AH124, 134 compressors are pan

mounted. Units 38AH094 and 104 compressors are mounted on rails.

Fig. 29 — 06E Compressors, Typical

38