Carrier 38AH044-084 User Manual

Page 31

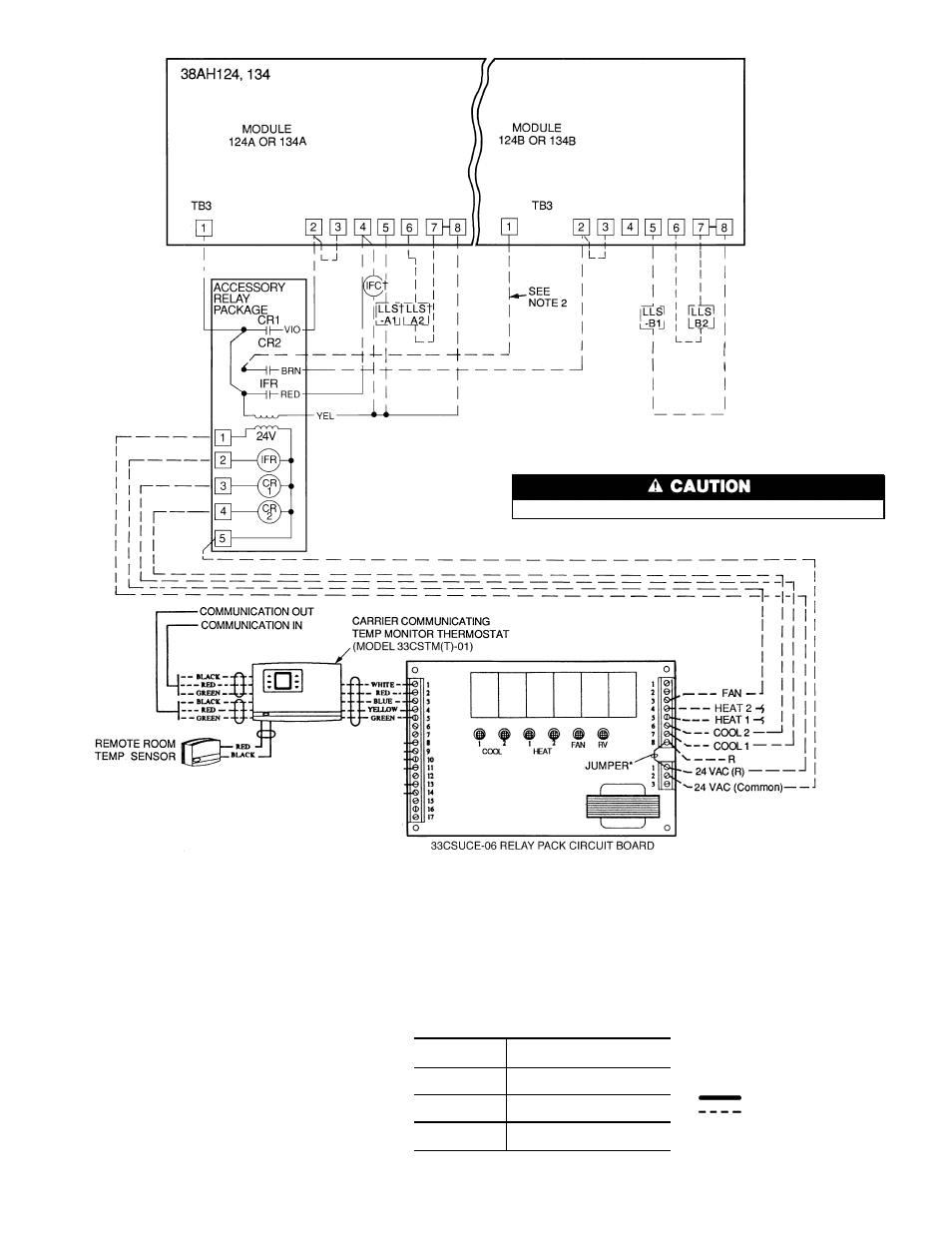

LEGEND

AWG

— American Wire Gage

C

— Compressor Contactor

CCPS — Capacity Control Pressure

Switch

CR

— Control Relay

HD

— Heating Device

IFC

— Indoor-Fan Contactor

IFR

— Indoor-Fan Relay

kcmil

— Thousand Circular Mils

LLS

— Liquid Line Solenoid

NEC

— National Electrical Code

(U.S.A. Standard)

R

— Heating Relay (field-

supplied 24-v sealed coil,

10 va maximum rating)

RV

— Reversing Valve

SDR

— Solenoid Drop Relay

TB

— Terminal Block

TR

— Timer Relay

Factory Wiring

Field Wiring

*Jumper removed only when separate 24-v trans-

former power source is used to power the 33CSUCE-06

relay pack.

†Field-supplied.

Internal 33CSUCE-06 relay contacts are rated for 1 amp/24 vac.

Fig. 23 — Field Wiring, One 2-Stage Thermostat — Units 38AH124 and 134

NOTES:

1. Liquid line solenoid valves LLS-A1 and A2 are used

for solenoid drop on Module 124A or 134A on cir-

cuit A. Liquid line solenoid valves LLS-B1 and B2

are used for solenoid drop for Module 124B or 134B.

Solenoid drop is a safety feature which prevents

refrigerant migration to the compressor during

the OFF cycle. It is recommended on all systems

and required on systems where piping exceeds

75 ft (22.9 m) in length.

2. Disconnect black wire from CR2 terminal 6; cap loose

end and secure. Connect new field-supplied wire

from CR2 terminal 6 to TB3 terminal 1 on module

124B or 134B.

3. The 33CSUCE-06 relay pack requires 10 va.

4. Factory wiring is in accordance with NEC; field modi-

fications or additions must be in compliance with

all applicable codes.

5. Wiring for field power supply must be rated 75 C

minimum. Use copper, copper-clad aluminum, or

aluminum conductors. Maximum incoming wire size

for each terminal block is 500 kcmil.

6. Terminal blocks (TB3) are for external field control

connections. Control connections must be Class 1

wiring.

7. Field-supplied components (IFC, LLS-A1,A2, and

LLS-B1,B2) must have a maximum sealed coil

rating of 30 va each (0.25 amp at 120 vac and

0.13 amp at 230 vac). Thermostats must have a

minimum pilot duty rating of 300 va (2.5 amps at

120 vac).

8. Replacement of factory wires must be with type

105 C wire or its equivalent.

9. Field-supplied liquid line solenoid valves installed

at the evaporator are required on all units.

10. Units have 175 va of power available for field-

installed accessories.

11. To minimize voltage drop, the following wire sizes

are recommended:

LENGTH —

Ft (M)

INSULATED WIRE — AWG

(35 C Minimum)

Up to 50

(15.2)

No. 18

50-75

(15.2-22.9)

No. 16

More Than 75

(22.9)

No. 14

31