0 installation, 1 unpacking and assembly, 2 enclosure disassembly – Rice Lake IQ Plus 355 Installation Manual V1.17 User Manual

Page 8: 3 cable connections, Installation, Aution, 7arning

4

IQ plus 355 Installation Manual

2.0

Installation

This section describes procedures for connecting load

cells, digital inputs, and serial communications cables

to the IQ plus 355 indicator. Instructions for field

installation of the analog output option and

replacement of the CPU board are included, along

with assembly drawings and parts lists for the service

technician.

•

Use a wrist strap to ground yourself and protect

components from electrostatic discharge (ESD)

when working inside the indicator enclosure.

•

This unit uses double pole/neutral fusing which

could create an electric shock hazard. Procedures

requiring work inside the indicator must be

performed by qualified service personnel only.

•

The supply cord serves as the power disconnect for

the IQ plus 355. The power outlet supplying the

indicator must be installed near the unit and be

easily accessible

2.1

Unpacking and Assembly

Immediately after unpacking, visually inspect the IQ

plus 355 to ensure all components are included and

undamaged. The shipping carton should contain the

indicator with attached tilt stand, this manual, and a

parts kit. If any parts were damaged in shipment,

notify Rice Lake Weighing Systems and the shipper

immediately.

The parts kit contains the items listed below:

•

Capacity, identification, and annunciator

labels. Annunciator labels (PN 53374)

provide replacement overlay decals for

labeling primary and secondary units LEDs.

•

6-position screw terminal (PN 70599) for

connector J1 and a 7-position screw terminal

(PN 70600) for connector J4 (see Figure 2-3

•

Two 8-32NC x 7/16 fillister head screws (PN

30623). These screws occupy the holes below

and on either side of the setup screw on the

indicator backplate (see Figure 2-4 on

page 7).

•

Four 8-32NC x 3/8 machine screws (PN

14862) for the indicator backplate (see #24 in

•

Six neoprene washers (PN 45042) for

backplate screws included in the parts kit.

•

Four rubber bumpers (“feet”) for the tilt stand,

PN 42149.

•

Five cable ties, PN 15631.

•

Two ferrites (PN 66730), used to reduce

susceptibility to radiate electromagnet

interference and EMI installation instructions

(PN 67970).

•

Three each of grounding clamps (PN 67550),

external tooth lock washers (PN 15133), and

kep nuts (PN 14676) for cable shield

grounding against the backplate.

2.2

Enclosure Disassembly

The indicator enclosure must be opened to connect

cables for load cells, communications, digital inputs,

and analog output.

The IQ plus 355 has no on/off switch.

Before opening the unit, ensure the

power cord is disconnected from the

power outlet.

Ensure power to the indicator is disconnected, then

place the indicator face-down on an antistatic work

mat. Remove the screws that hold the backplate to the

enclosure body, then lift the backplate away from the

enclosure and set it aside.

2.3

Cable Connections

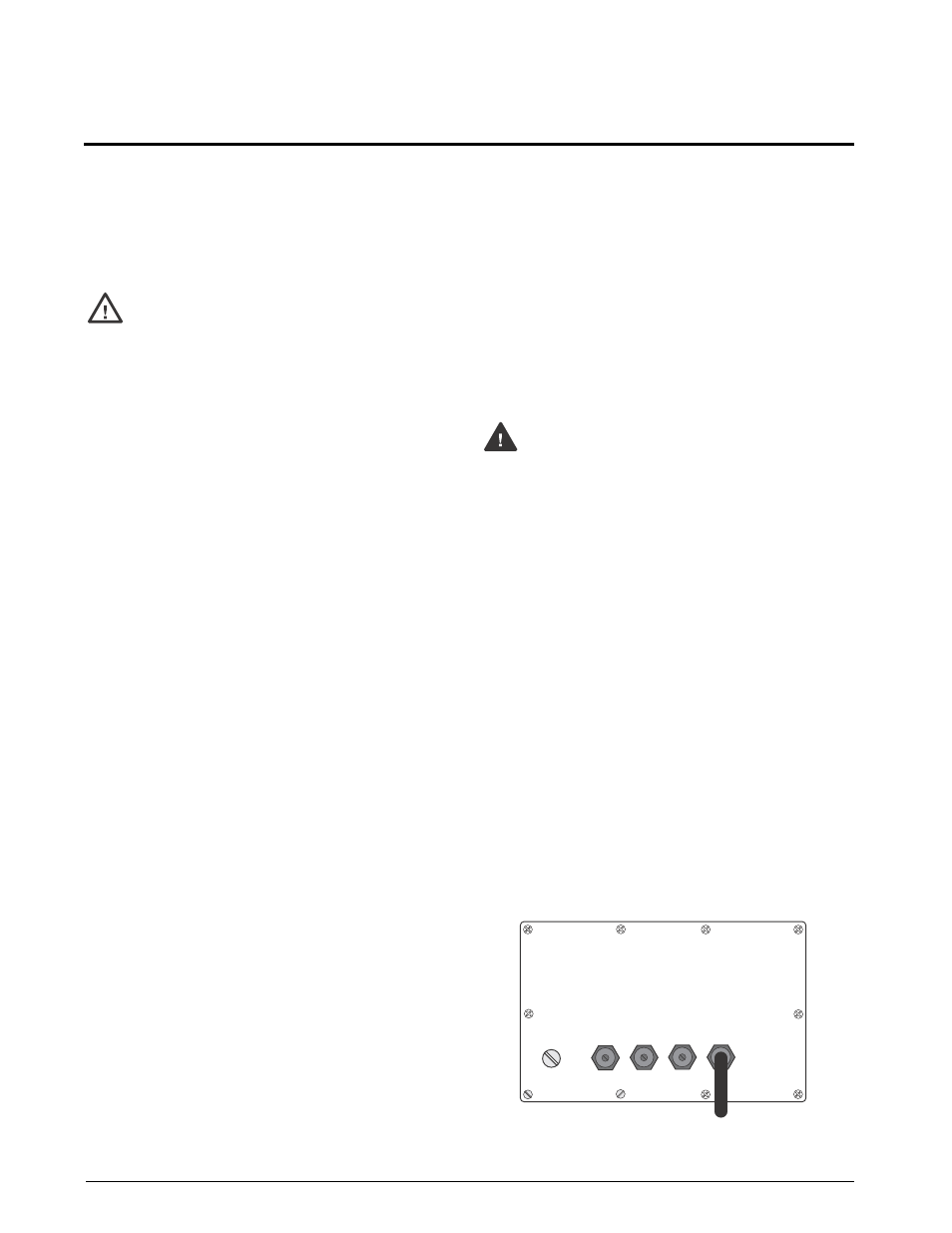

The IQ plus 355 provides four cord grips for cabling

into the indicator: one for the power cord, three to

accommodate load cell, communications, digital

inputs, and analog output cables. Two of the three free

cord grips come with a plug installed to prevent

moisture from entering the enclosure. Depending on

your application, remove the plug from any cord grip

that will be used and install cables as required.

NOTE:

Because the IQ plus 355 has no on/off switch,

the power cord serves as the power disconnect. The

power outlet must be located close enough to the

indicator to allow the operator to easily disconnect

power to the unit.

Figure 2-1 shows the recommended assignments for

the IQ plus 355 cord grips.

Figure 2-1. Recommended Cord Grip Assignments

#AUTION

7ARNING

"$1PXFS$PSE

-PBE$FMM$BCMF

4FSJBM$PNNVOJDBUJPOT

"OBMPH0VUQVU %JHJUBM*OQVU