Concave curves, Trippers – Rice Lake BCi Belt Scale - Installation & Operation Manual Version 2.00 User Manual

Page 16

10

BCi

Installation & Operation Manual

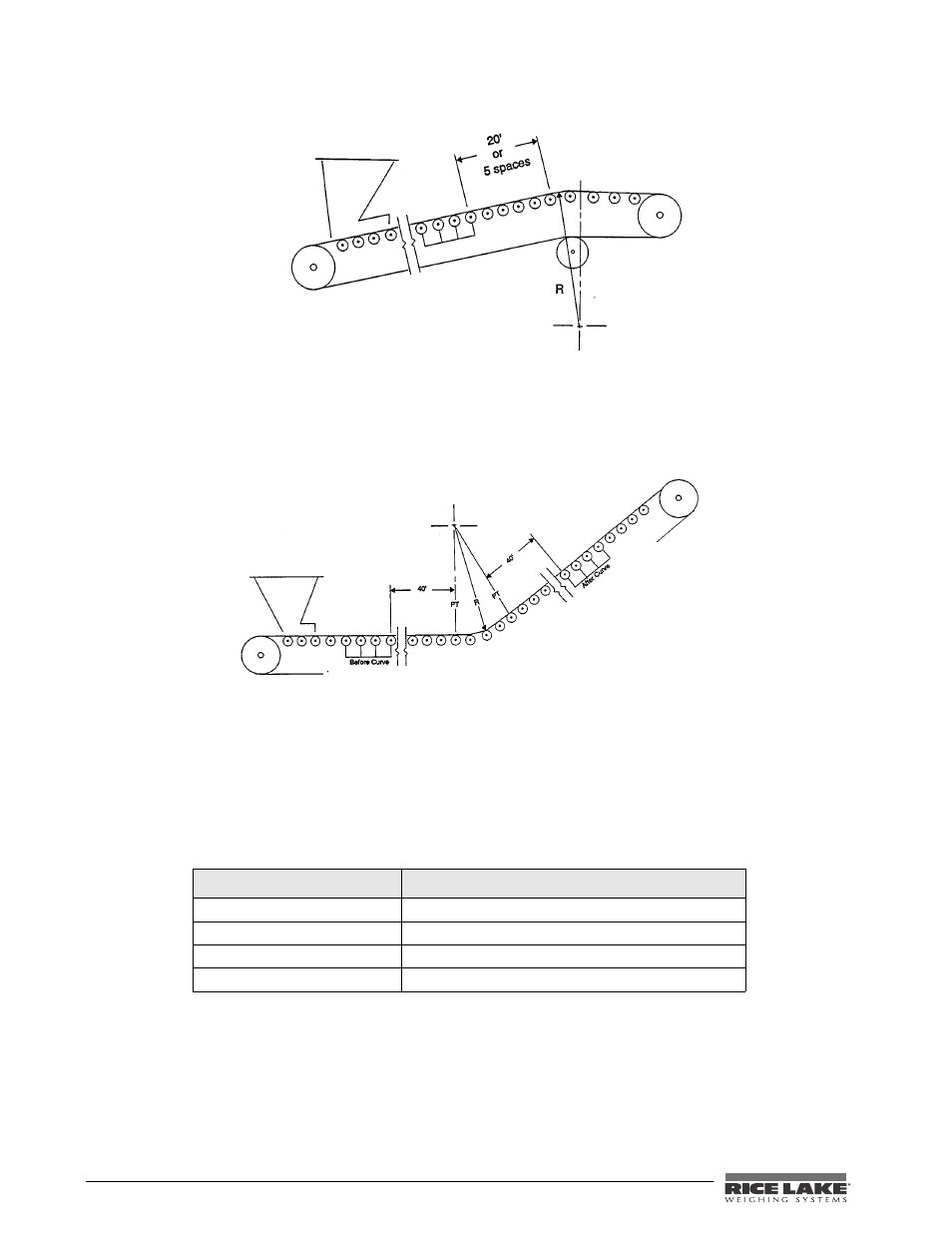

Figure 1-10. Convex Curved Conveyor

Concave Curves

Conveyors that have concave curves should be avoided or the scale should be located in a section of the conveyor

that is not affected by the curve. If there is a curve, the belt must remain in contact with the idler rollers at all

times for at least 20 feet (6m).

Figure 1-11. Concave Curved Conveyor

Trippers

Tripper belts, mechanical sweep samplers, training idlers, feed points, skirt boards and other device that also

affect belt tension should be located away from the scale carriage.

If the scale must be installed on a conveyor with a tripper, then the same rules apply as for an installation in a

concave conveyor.

The following table offers basic guidelines for minimum distances and applies to both horizontal and incline

conveyors.

Speed Sensor or Magnetic Shaft Encoder Mounting Location - (Optional items)

The optional speed sensor location is not as critical as scale carriage location, however improper installation of

the speed sensor will significantly affect the performance of the scale system. The speed sensor must give an

accurate representation of the speed of the material and travel of the belt.

Type of Conveyor

Distance from Scale Carriage

End of skirt boards or feed point

15’ or 4 idler spaces whichever is greater

Training idler or sweep sampler

30’ or 8 idler spaces, whichever is greater

Tripper or concave curve

40’ from the first idler affected by the curve

Convex curve or head pulley

20’ or 5 idler spaces

Table 1-3. Distance Points from Conveyor to Scale Carriage