Cooper Instruments & Systems Model 7i Professional Force/Torque Indicator User Manual

Page 12

Model 7i Digital Force / Torque Indicator

User’s Guide

11

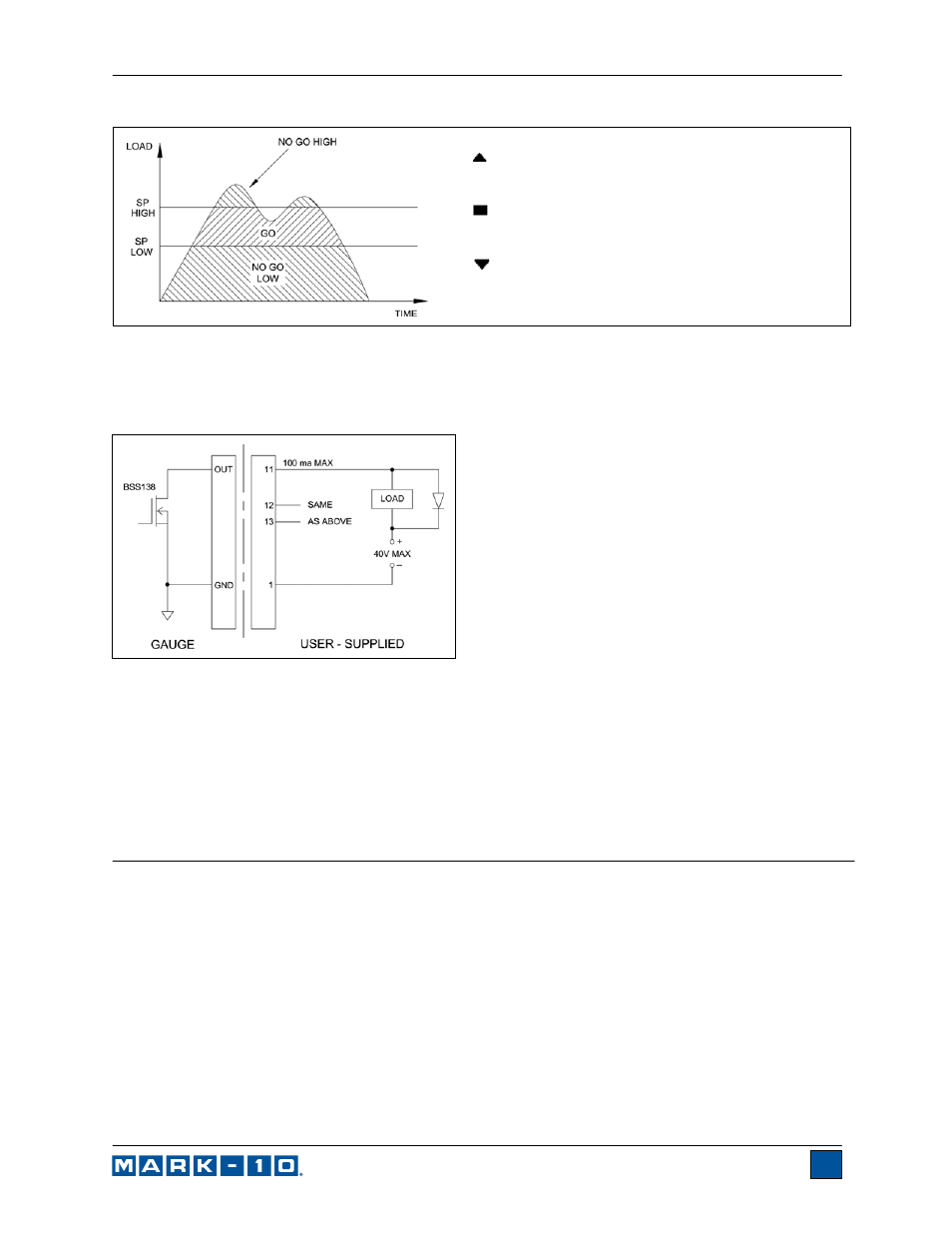

– the displayed value is greater than the upper

set point (NO GO HIGH)

– the displayed value is between the set points

(GO)

– the displayed value is less than the lower set

point (NO GO LOW)

Note: Set point indicators and outputs reference the displayed reading, not necessarily the current live

load.

6.3 Set Point Outputs Schematic Diagram

6.4 Using Set Points to Control a Mark-10 Motorized Test Stand

When using set points to stop/cycle Mark-10 motorized test stands, the upper and lower set points must

be set to opposite measuring directions. Both set points must be set, even if the intended application is

to stop/cycle at only one of the set points. The opposite set point should be a value sufficiently large that it

does not get triggered during the course of the test.

For certain Mark-10 test stands, the upper and lower set point directions are reversed.

7 BREAK DETECTION

The break detection function identifies when a sample has broken, clicked, slipped, or otherwise reached

a peak load and then fell by a specified percentage drop. Upon detection of the break, the indicator can

perform several automatic functions, depending on the mode in which break detection is enabled, as

follows:

1. Transmit the peak reading (Auto Output).

2. Save the peak value to memory (Auto Storage).

3. Zero the primary and peak readings (Auto Zero).

4. Toggle a pin (for example, to stop crosshead movement on a Mark-10 motorized test stand).

Break detection functions and settings are configured from a central location, and apply to any mode in

which it is enabled. Refer to the Operating Modes section for details on configuring each mode.

7.1 Configuration