Cooper Instruments & Systems ELF 4200 Flexiforce Paper Thin Sensor User Manual

Page 36

CF10

33

6/24/08 Rev. H

6.1 CALIBRATION GUIDELINES

The following guidelines should be considered when calibrating a sensor:

• Apply a calibration load that approximates the load to be applied during system use, using dead weights or a

testing device (such as an MTS or Instron). If you intend to use a "puck" during testing, also use it when

calibrating the sensor. See Sensor Loading Considerations for more information on using a puck.

• Avoid loading the sensor to near saturation when calibrating. If the sensor saturates at a lower load than desired,

adjust the "Sensitivity".

• Distribute the applied load evenly across the sensing area to ensure accurate force readings. Readings may vary

slightly if the load distribution changes over the sensing area.

Note: Read the Sensor Performance Characteristics section before performing a Calibration.

6.2 CALIBRATION PROCEDURE

IMPORTANT! Sensors must be properly conditioned prior to calibration and use.

1. Select

File -> New

to open a new Real-time window. If you wish to use a previously saved calibration file,

select Tools -> Load Calibration, enter the calibration file name and path, and click OK.

2. Load each sensor with a known force.

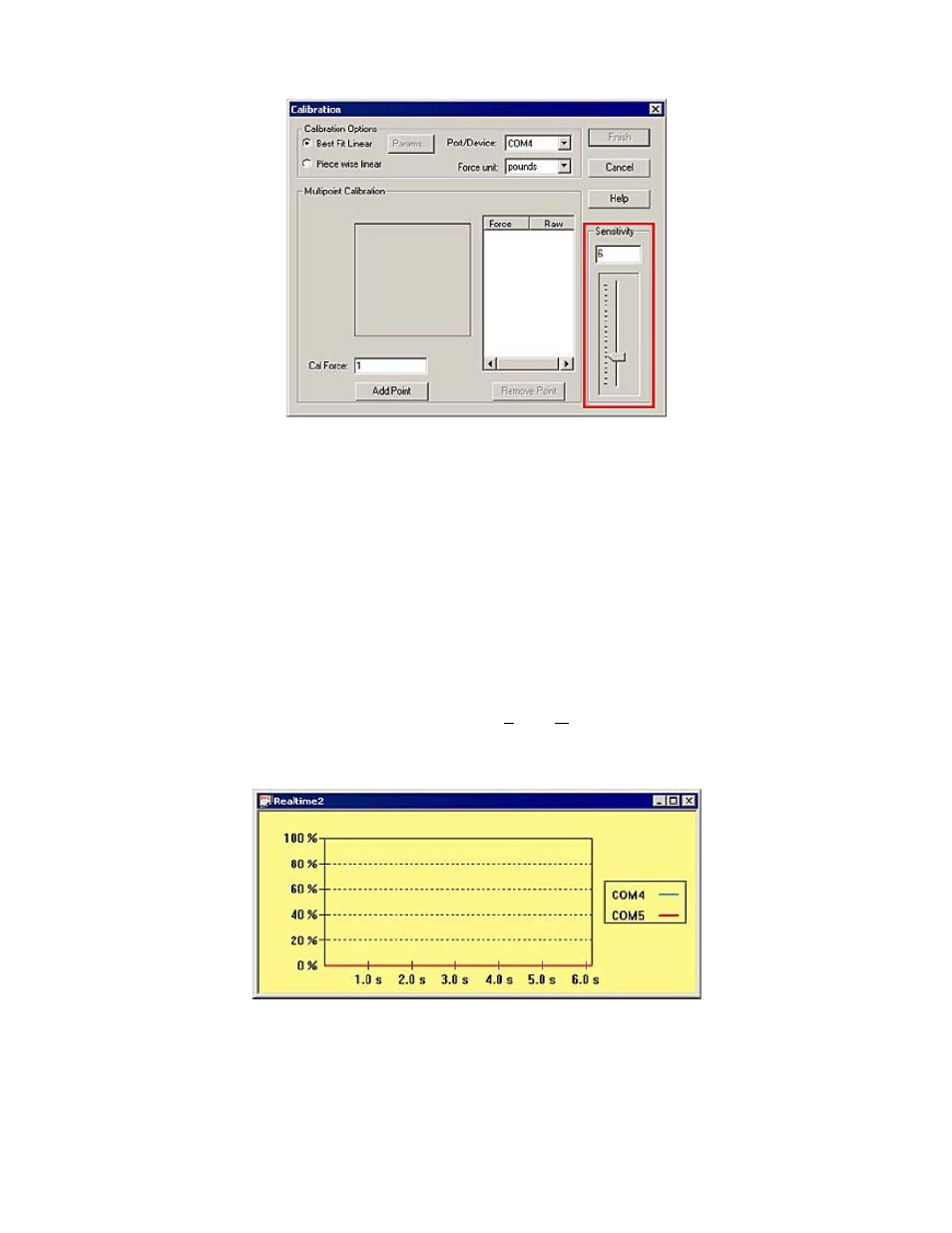

3. Click

Tools -> Change Sensitivity

. If you have the Multi-Handle ELF system, adjust sensitivity for each

sensor, if necessary, by either dragging the slider up and down, or entering an integer between 1 and 20

(default is 12). The "Sensitivity" should be adjusted whenever necessary to keep the force display in a usable

range.