2 troubleshooting guide for vacuum manifold – Bio-Rad Bio-Plex® 200 Systems User Manual

Page 40

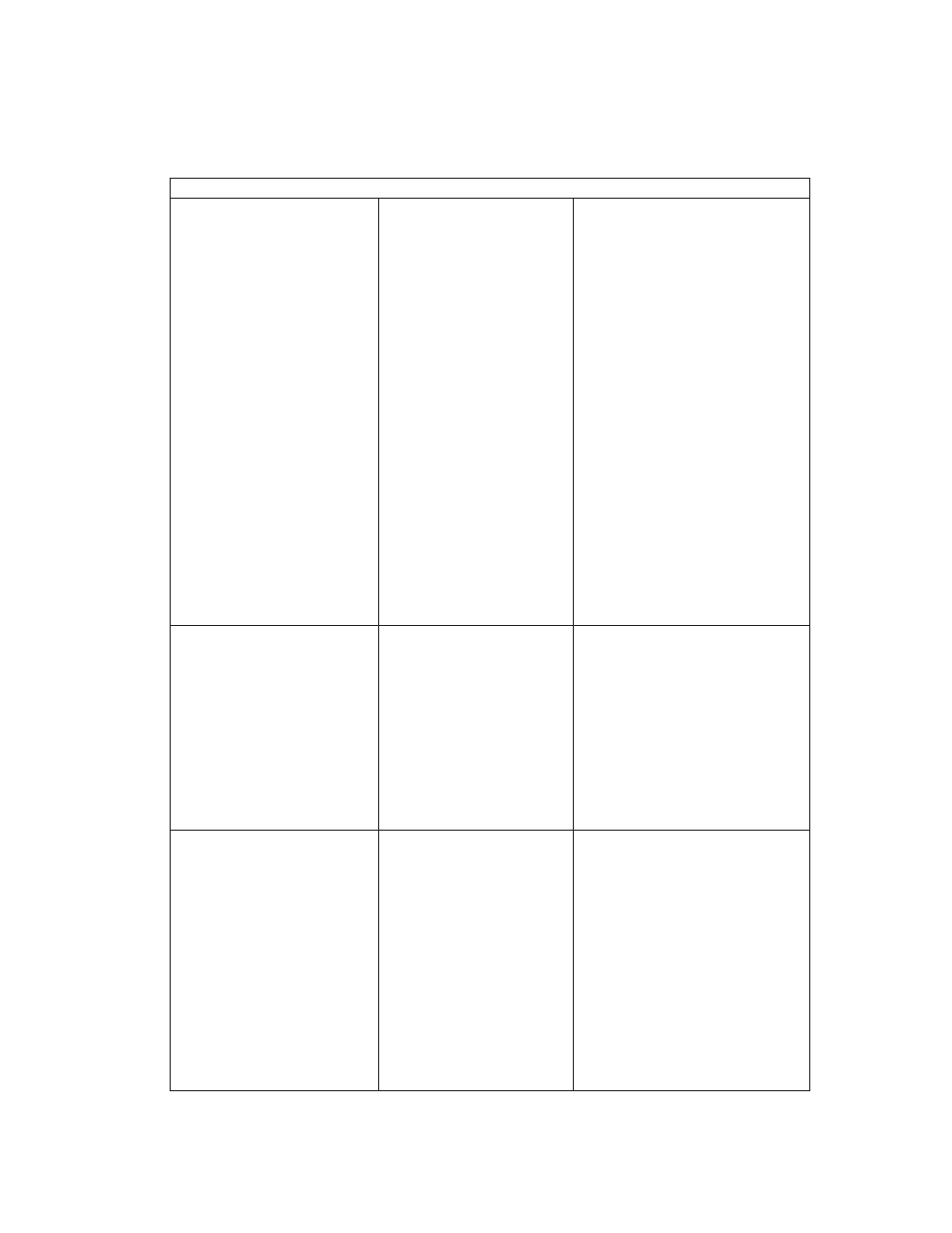

5.2 Troubleshooting Guide for Vacuum Manifold

Message/Problem

Causes

Solution

No Flow/no vacuum.

Lid on plate

Remove lid.

All wells not wet, or

Wet unused wells with Milli-Q

unused wells not covered

water. (You can reuse these wells

or sealed

later.) Or, tape the unused wells

with sealing tape. If you need to seal

partial rows or columns, seal the

unused rows or columns with tape

and leave the adjacent unused row

partially sealed. Then wet with buffer

since it is difficult to make seals at the

row edge.

Poor alignment of plates

Align plates.

with gasket

Vacuum trap filled

Empty trap.

Filter on pump clogged

Replace filter.

Pump not turned on

Turn on pump.

Manifold ON/OFF valve in

Turn to ON position.

OFF position

Manifold pressure gauge

Turn up to higher value.

turned to the lowest value

Damaged gasket

Replace gasket.

Gauge plug missing

Replace gauge plug in side of

manifold ring using hex key wrench.

Wells do not empty at the

Lid on plate

Remove lid.

same time/uneven flow.

Vacuum line turned off or

Clear line and repeat.

clogged

Debris in sample

Remove cellular debris prior to

adding to wells.

Bad plate-to-vacuum

To ensure a good plate-to-manifold

manifold seal

seal, put pressure on corners of

plate.

Too many beads

Check to ensure that proper bead

concentration was used.

Leakage during incubation.

High surfactant

Lower the concentration.

concentration

Failure to blot under-drain

Blot under-drain.

after filtration and before

incubation

Under-drain contacting

Place plate on smooth, flat surface

surface

so nothing touches the underdrain

spouts.

Absorbent material

Place on flat, nonabsorbent

contacting under-drain

material (such as lid).

Excessive agitation or

Mix using orbital table at a lower

vibration

volume (maximum 200 µl on shaker,

340 µl without a shaker) or use lower

speed.

35

www.bio-rad.com/bioplex/