Drive-line shear pin, Marker maintenance (option), Marker shear bolt replacement – Great Plains YP625PD Operator Manual User Manual

Page 86: Marker grease seal cap, Drive-line shear pin marker maintenance (option), Led. see “ marker

82

YP625PD

Great Plains Manufacturing, Inc.

401-754M

02/23/2011

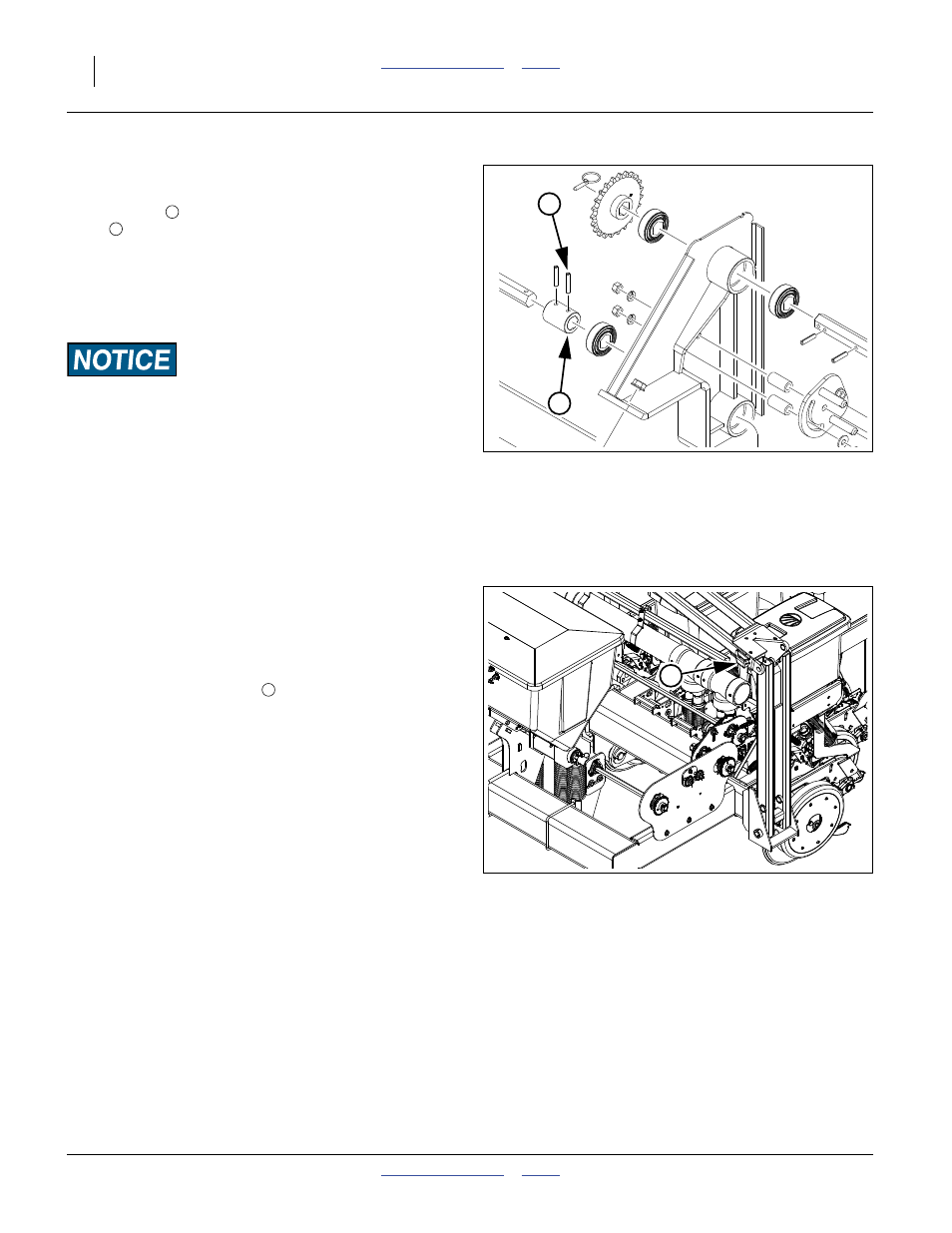

Drive-Line Shear Pin

Refer to Figure 90

The spirol pin

that connects main transfer shaft

collar

to the transmission shears if an excessive load

is put on the shaft.

Infrequent or improper lubrication causes binding of

moving parts within the planter. This binding can cause

the spirol pin to shear, preventing more serious damage

to other planter parts.

Machine Damage / Nuisance Shear Risks:

Do not use arbitrary spirol pins. Replace sheared pins with

cotter pins of the same size. Strong pins may fail to shear,

causing more serious damage elsewhere. Weaker pins are

prone to nuisance shears. Refer to current Parts Manual for

correct spirol pin replacement part number.

Marker Maintenance (Option)

See also:

“Initial Marker Setup (Option)” on page 111,

“Marker Operation (Option)” on page 32, and

“Marker Disk Adjustment” on page 47

Marker Shear Bolt Replacement

Refer to Figure 91

If a marker gets caught or hits an obstruction, it is

designed to fail a shear bolt

at the fold, pivot on a

second bolt (not visible in Figure), and swing back.

The shear bolt is a hex head cap screw,

5

⁄

16

-18 x 1

1

⁄

2

in

Grade 5, Great Plains part number 802-012C, plus a

5

⁄

16

-18 lock nut, Great Plains part number 803-011C.

Note: If an exact replacement is not immediately

available, temporarily substitute an M8x1.25 Class

8.8 bolt and nut.

Install a replacement shear bolt on the vertical face on

the side opposite from the pivot bolt. Do not use a higher

grade bolt, or marker hang-ups may result in machine

damage. Do not use a lower grade bolt, or you may

experience nuisance shears.

Marker Grease Seal Cap

If grease seal cap for marker-disk-hub bearings is

damaged or missing, disassemble and clean hub.

Repack with grease and install new seal or grease cap.

Figure 90

Transmission Shear Pin

29884

2

1

Figure 91

Marker Shear Bolt

31794

3

3