Population troubleshooting charts – Great Plains YP625PD Operator Manual User Manual

Page 70

66

YP625PD

Great Plains Manufacturing, Inc.

401-754M

02/23/2011

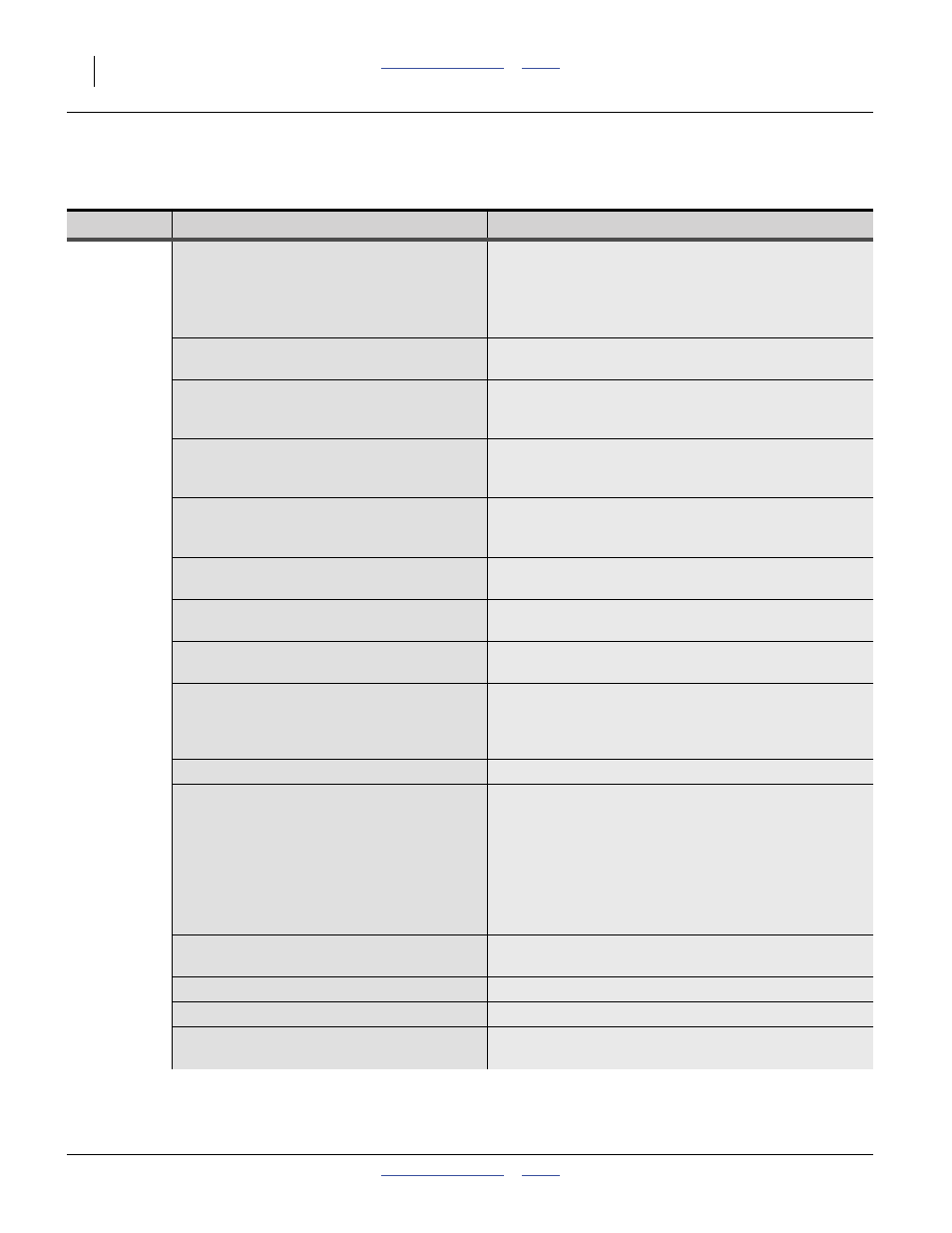

Population Troubleshooting Charts

Population Too Low

Problem

Cause

Solution

Overall

Low

Population

Incorrect seed rate

Using Seed Rate Manual, check:

• seed disk selection,

• Range/Transmission sprocket setup, and

• tire size and inflation.

Empty pockets on disk (skips) due to

insufficient air pressure.

Methodically increase the meter pressurization.

See “Fan and Adjustment” on page 41.

Empty pockets on disk (skips) due to sticky

seed treatments not allowing seed to rapidly

fill the pockets.

Increase seed lubricant.

Empty pockets on disk (skips) due to rough

field conditions causing seeds to fall from

the disks.

Decrease field speed or increase the air pressure in

the meter.

Empty pockets on disk (skips) due to seed

pool too low, and seeds are not filling every

pocket on the disk.

Open shutter one notch.

Empty pockets on disk (skips) due to disk

speed too high, and pockets are not filling.

Decrease field speed or change to a higher cell count

disc.

Empty pockets on disk (skips) due to

singulation (4 tufted) brush too aggressive.

Check for matted, stuck together fibers. Wash, scrape

clean, or replace as needed.

Empty pockets on disk (skips) due to seed

too big for pocket.

Select the correct disk for the seed size.

Seeds are not falling from disk, and get

carried past drop zone. Static electricity can

cause small, lightweight seeds to cling to the

pocket and not fall out.

The graphite component of Ezee Glide Plus addresses

this issue. Increase the amount of Easy Glide Plus

and/or more thoroughly mix the lubricant into the seed.

Air pressure too low, as confirmed by gauge. Increase fan speed or reduce butterfly valve setting.

Air pressure too low, but gauge reading is

within range or reading high.

• Inspect the 6.4 cm sample lines from the row units

up to the sensor chamber for leaks (page 65).

• Make sure all non-planting rows have blank disks

and shutters are closed (page 58).

• Re-zero the gauge with the fan off (page 65).

• Check gauge vent line for kinks, pinches or plugging

Excess field speed

Plant within speed ranges recommended in Seed Rate

Manual.

Incorrect speed sensor constant.

Perform speed calibration per seed monitor manual.

Incorrect magnetic speed sensor gap.

(Option) Incorrect radar speed sensor angle. With planter lowered, check radar speed sensor angle

per DICKEY-john

®

recommendations.