Rate: seed inlet shutter, Rate: meter pressurization, Rate: checking – Great Plains YP625PD Operator Manual User Manual

Page 44

40

YP625PD

Great Plains Manufacturing, Inc.

401-754M

02/23/2011

5. Rate: Seed Inlet Shutter

A consistent seed rate results from having a consistent

number of seeds (usually one) in each pocket of the

seed disk, avoiding “skips” (fewer seeds per pocket) and

“doubles” (excess seed per pocket).

Refer to Figure 31

One of the factors that affects seed pickup at the disk is

having an optimal seed pool (page 55). The depth of the

seed pool is controlled by the seed inlet shutter

.

Each Seed Rate chart specifies a suggested initial

shutter setting. See “Seed Inlet Shutter Adjustment” on

page 54 for setting details, and further adjustment.

At unused rows, set the shutter to zero/closed to prevent

loss of meter pressurization air. Install a blank disk. See

“Row Unit Shut-Off” on page 57.

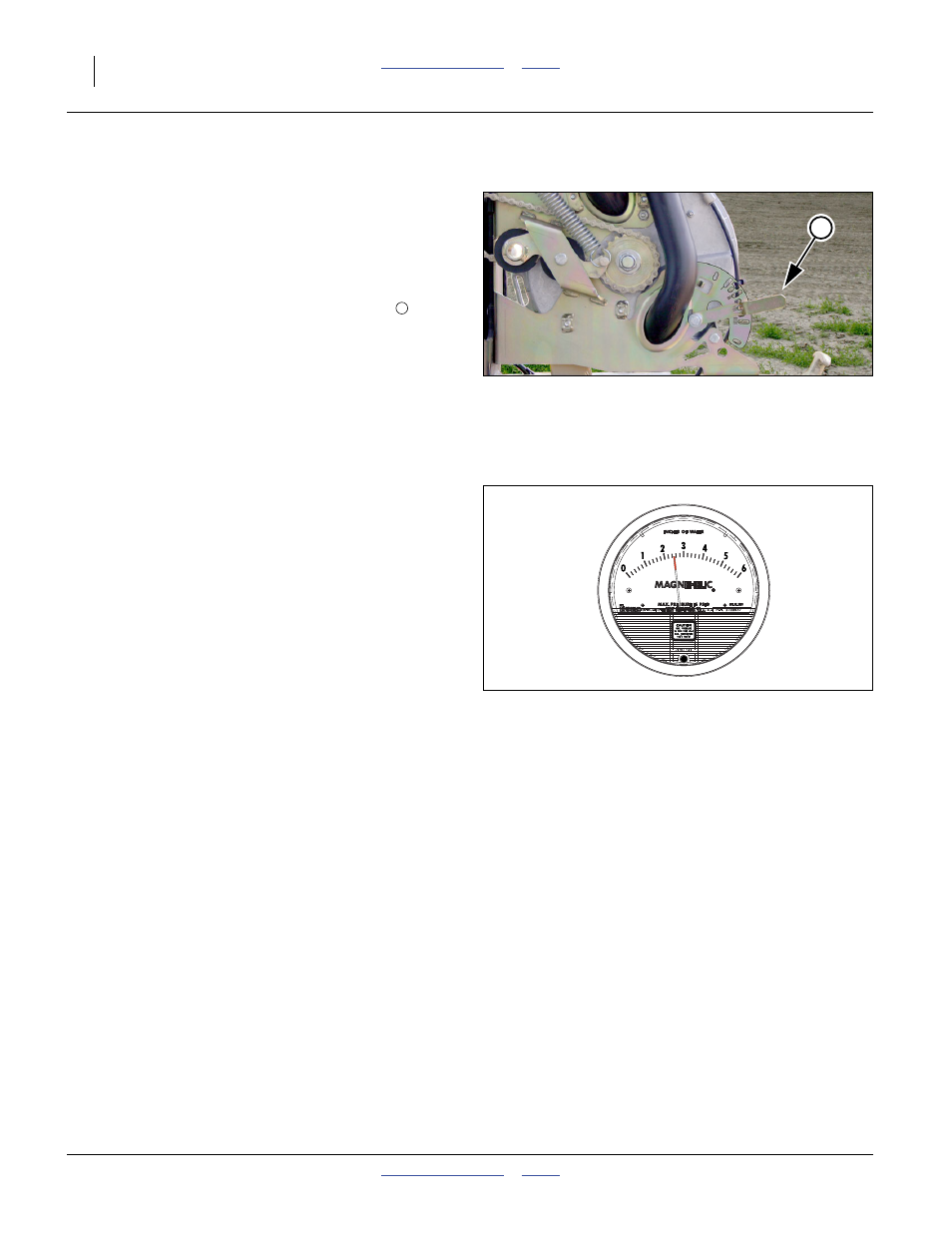

Refer to Figure 32

(which depicts a typical reading for some densities of corn)

A major factor that affects seed pickup at the disk is

optimal meter pressurization. Fan air holds the seed in

the disk pockets until they pass the drop brush

(page 31).

The Seed and Fertilizer Rate manual has a section with

suggested initial manifold pressures, which may be a

single value, or a graph based on seed density.

Manifold pressure is set by a combination of tractor

circuit lever and fan butterfly valve (page 30). See “Air

System Operation” on page 27.

7. Rate: Checking

Although the seed monitor reports a computed

population based on seeds sensed, only an actual furrow

check provides certainty about the actual seeding rate.

See the Seed and Fertilizer Rate manual.

Figure 31

Seed Inlet Shutter: Setting III

29607

5

5

Figure 32

Meter Pressure Gauge

29842