Press wheel centering – Great Plains YP625PD Operator Manual User Manual

Page 66

62

YP625PD

Great Plains Manufacturing, Inc.

401-754M

02/23/2011

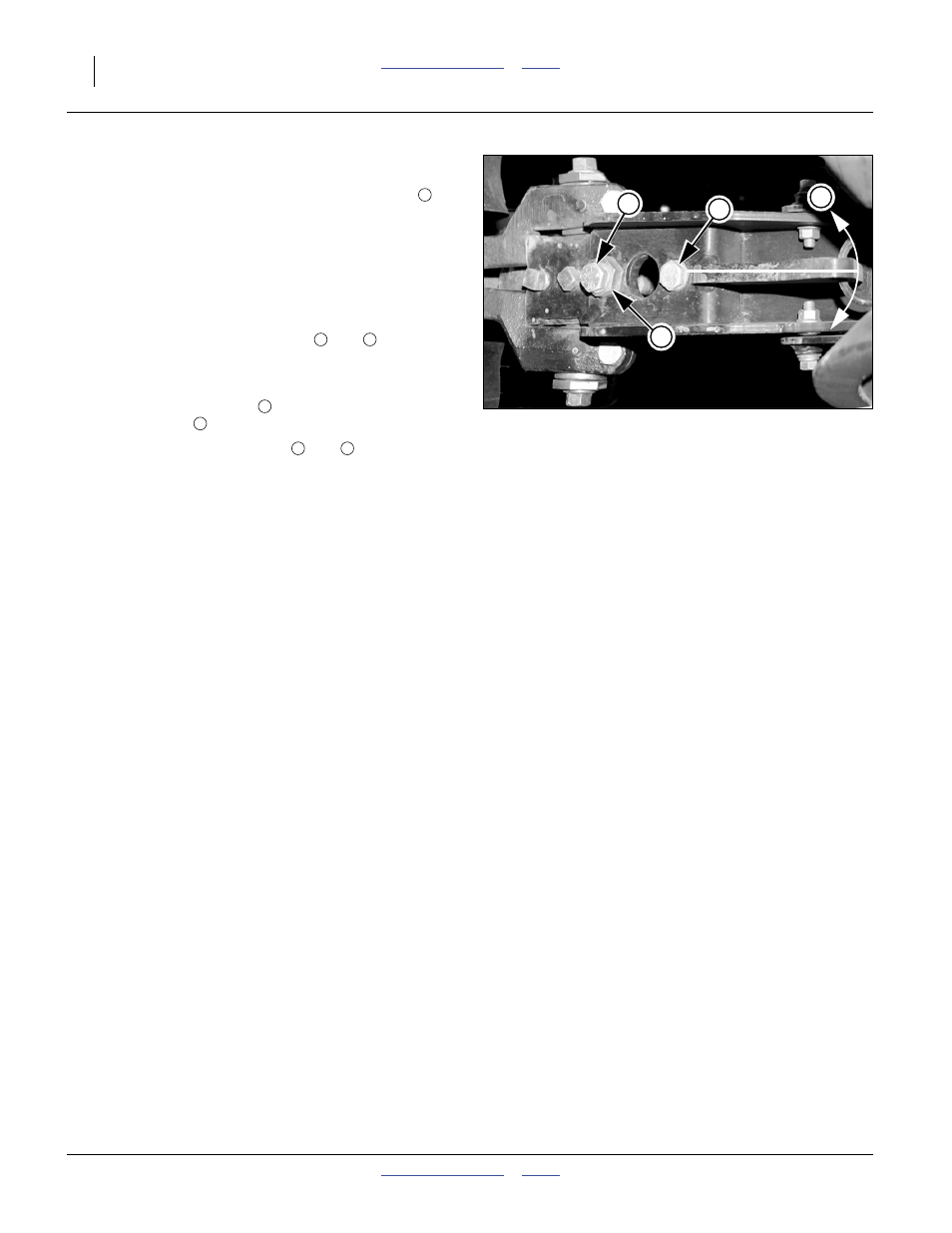

Press Wheel Centering

If one press wheel is running in the seed trench, or the

wheels are not centered over the trench, the angle

of

the press wheel assembly can be adjusted as follows:

Refer to Figure 75

1.

Determine how far, and in which direction, the press

wheel assembly needs to move to center the wheels.

2.

Raise planter and install lift assist cylinder locks. See

“Lift Cylinder Locks” on page 19.

3.

Loosen the

1

⁄

2

in hex-head bolts

and

.

Note: Do not loosen the square-head bolts forward of the

hex-head bolts.

4.

Turn the hex head cam

under the forward hex

head jam bolt

, and move the required amount.

5.

Tighten both hex head bolts

and

.

If press wheel adjustments do not provide satisfactory

furrow closing, your conditions may require alternate

press wheels. A variety of wheel assemblies are

available. Consult your Great Plains dealer.

ll

Figure 75

Press Wheel Centering

(View from beneath opener)

25277

3

2

1

4

1

2

3

4

3

2

3

- 1200 Parts Manual (210 pages)

- 706NT Material Rate (46 pages)

- 706NT Material Rate (50 pages)

- 2N-2410 Operator Manual (56 pages)

- 2N-2410 Operator Manual (48 pages)

- 12 Series Drills Assembly Instructions (6 pages)

- X-PresS 2006 Assembly Instructions (50 pages)

- TM500 Operator Manual (62 pages)

- 2010HDP Operator Manual (166 pages)

- YP1630F Material Rate (42 pages)

- YP2425 Operator Manual (162 pages)

- 3S-5000 Operator Manual (94 pages)

- 3PYP Operator Manual (188 pages)

- 3N-3010P Assembly Instructions (2 pages)

- 3N-3010 Assembly Instructions (9 pages)

- 3N-3010P Assembly Instructions (9 pages)

- PFH-15 Predelivery Manual (23 pages)

- PFH-15 Operator Manual (26 pages)

- PFH-15 Operator Manual (46 pages)

- P15126 Serial No 12724 (34 pages)

- DVN 8321 Operator Manual (38 pages)

- 3P500 Assembly Instructions (22 pages)

- 605NT Assembly Instructions (4 pages)

- 3P600 Assembly Instructions (12 pages)

- 605NT Assembly Instructions (8 pages)

- CPH-12 Assembly Instructions (3 pages)

- YP1625A-2420 24 Row 20-Inch Quick Start (6 pages)

- 8323 FCF Predelivery Manual (124 pages)

- P13937 (20 pages)

- 3323 DH Parts Manual (114 pages)

- YP3025-1820 25 Series 18 Row 20 Inch Quick Start (5 pages)

- CF500 Operator Manual (38 pages)

- PFH-15 Assembly Instructions (30 pages)

- 3500TM Parts Manual (106 pages)

- 1800TM Parts Manual (158 pages)

- YP2425A-2470 24 Row 70 cm Quick Start (5 pages)

- Simba Culti Press Operator Manual (38 pages)

- RU1999 Parts Manual (58 pages)

- 3N-30P Assembly Instructions (10 pages)

- 2510HDP Operator Manual (180 pages)

- YP1220 Parts Manual (136 pages)

- 3P500 Material Rate (68 pages)

- YP2425-3620 36 Row 20 Inch Quick Start (5 pages)

- 706NT Operator Manual (22 pages)

- 706NT Operator Manual (53 pages)