Speed settings, Pulses per rev, Wheel pulses per 400 feet – Great Plains ADC2220 Operator Manual User Manual

Page 61: Speed calibration, Wheel pulses per 400 feet speed calibration

Great Plains Manufacturing, Inc.

Loup II Monitor Operation

57

2012-10-17

167-073M

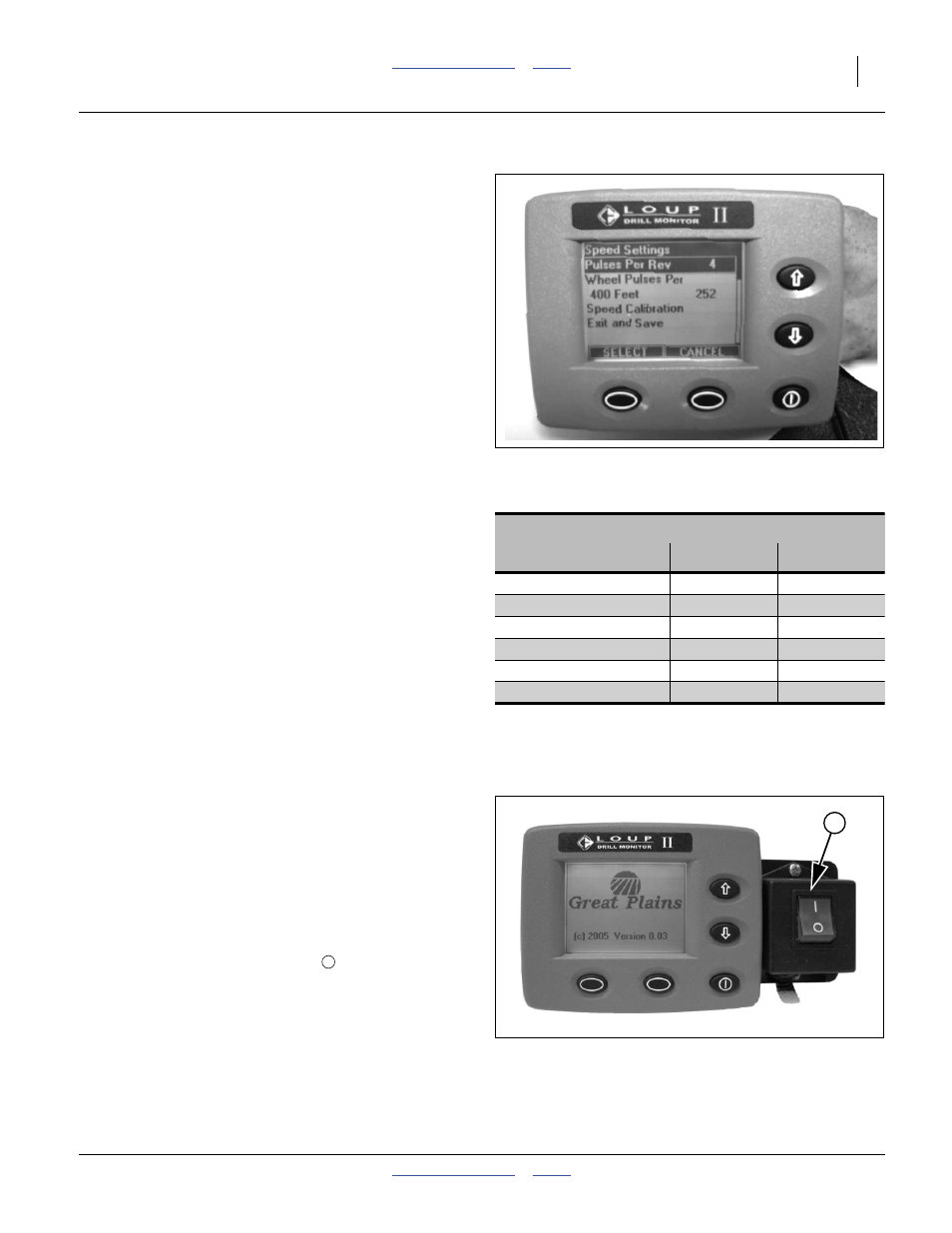

Speed Settings

Refer to Figure 67

Pulses Per Rev

Pulses per Rev (revolution) are the number of magnets

the implement mounted speed sensor sees in one

revolution of the ground drive clutch shaft. The magnet

assembly is on the inner end of this shaft.

The factory default is 4 pulses per rev (PPR), which is

correct for current ADC2220 carts. Older carts may have

2 or 4 magnets on the shaft, visible as short metal rods

in the polymer magnet housing.

Wheel Pulses Per 400 Feet

This is the ground speed calibration number for a

implement mounted speed sensor. Refer to page 57 for

calibration instructions.

The factory default for speed PPR is:

252

for compatibility with older monitors as a service

replacement. This is approximately correct only for

ADI334.

Approximate PPR values for various drills are shown in

the table at right. Do not rely on these values for planting.

Use them as a cross-check of your calibrated rate. If your

calibrated PPR is significantly different from the table, it

may indicate a mechanical fault, or that your cart is not

correctly setup for your drill.

Speed calibration is necessary for all air drills, including

ADI334. The default PPR is incorrect for newer drills, and

the table values at right are only approximate.

Re-calibration is recommended as tires wear or field

conditions change (which can alter effective rolling radius

of tires). Always cross-check the monitor reported speed

with the tractor speedometer or other reference.

Speed Calibration

All new systems require a ground speed calibration to

ensure accurate area totals and accurate ground speed

readings. To complete the calibration, measure a course

400 feet (121.9 m) long preferably on level ground with a

start and finish point. The drill must be in the down

position throughout this procedure.

Refer to Figure 68

1.

Position the drill at the start of the course, in lowered

field position. Set clutch switch

to On.

Note: During the calibration the monitor is looking for the

number of pulses produced from the drill mounted

sensor or in the case of radar, the number of radar

pulses. The monitor does not display 400 when the

speed calibration is complete rather it displays the

pulses counted in 400 feet.

Figure 67

Speed: Pulses per Revolution

29055

Pulses per Rev (Speed)

in 400 feet (121.9 m)

Imperial

a

a. Use “Imperial” for U.S. customary units.

Metric

ADI334

253

253

ADI345

331

331

CTA4000

296

296

CTA4000HD

296

296

NTA3010

226

226

NTA3510

253

253

Figure 68

Clutch Switch On

29013

1

1