Press wheel centering, Single press wheel, Press wheel centering single press wheel – Great Plains PD8070 Operator Manual User Manual

Page 61

Great Plains Manufacturing, Inc.

Adjustments

57

2014-07-23

401-479M

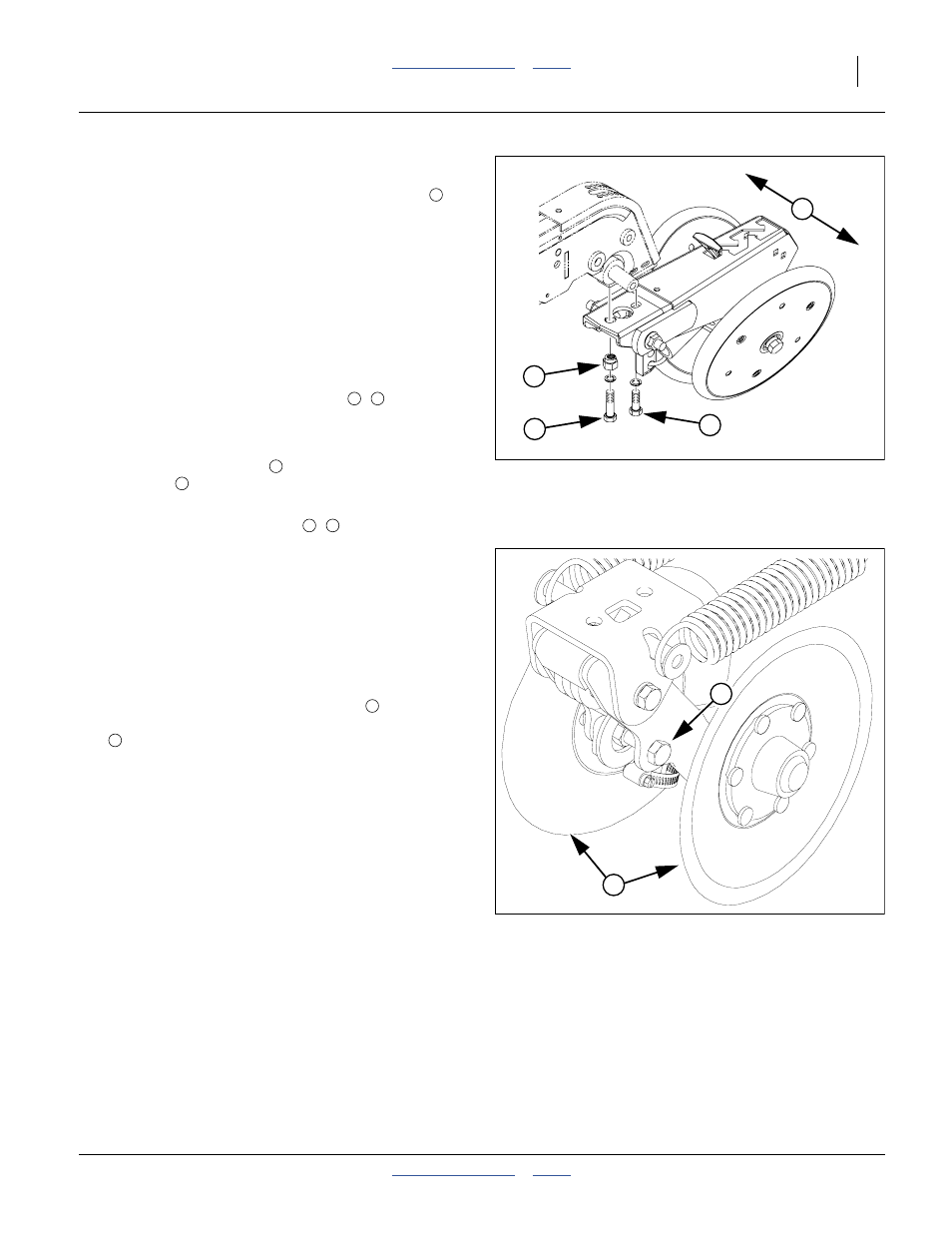

Press Wheel Centering

If one press wheel is running in the seed trench, or the

wheels are not centered over the trench, the angle

of

the press wheel assembly can be adjusted as follows:

Refer to Figure 64

1.

Determine how far, and in which direction, the press

wheel assembly needs to move to center the wheels.

2.

Raise planter and install lift assist cylinder locks. See

“Lift Cylinder Lock-Up” on page 62.

3.

Pick some reference points on the unit to be

adjusted and an adjacent row unit. Measure the

distance between them.

4.

Loosen the

1

⁄

2

inch hex-head bolts

,

.

Note: Do not loosen any square-head bolts forward of the

hex-head bolts.

5.

Turn the hex head cam

under the forward hex

head bolt

, and obtain the new distance between

the reference points.

6.

Tighten both hex head bolts

,

.

Single Press Wheel

The single 6

1

⁄

2

×12 press wheel with dual closing disks is

one of two available press wheels for the PD8070. See

page 96 for ordering information.

For proper seed-to-soil contact, the closing disks must

have enough down pressure to close the seed furrow

without unnecessary soil compaction.

Refer to Figure 65

To adjust down pressure on closing disks

, ratchet

spring cam to next cam height by turning head of support

bolt

clockwise.

Figure 64

Dual Press Wheel Centering

17889

1

2

3

4

1

2

3

4

3

2

3

Figure 65

Closing Disk Adjustment

14913

2

1

1

2