Contact drive tension – Great Plains PD8070 Operator Manual User Manual

Page 43

Great Plains Manufacturing, Inc.

Adjustments

39

2014-07-23

401-479M

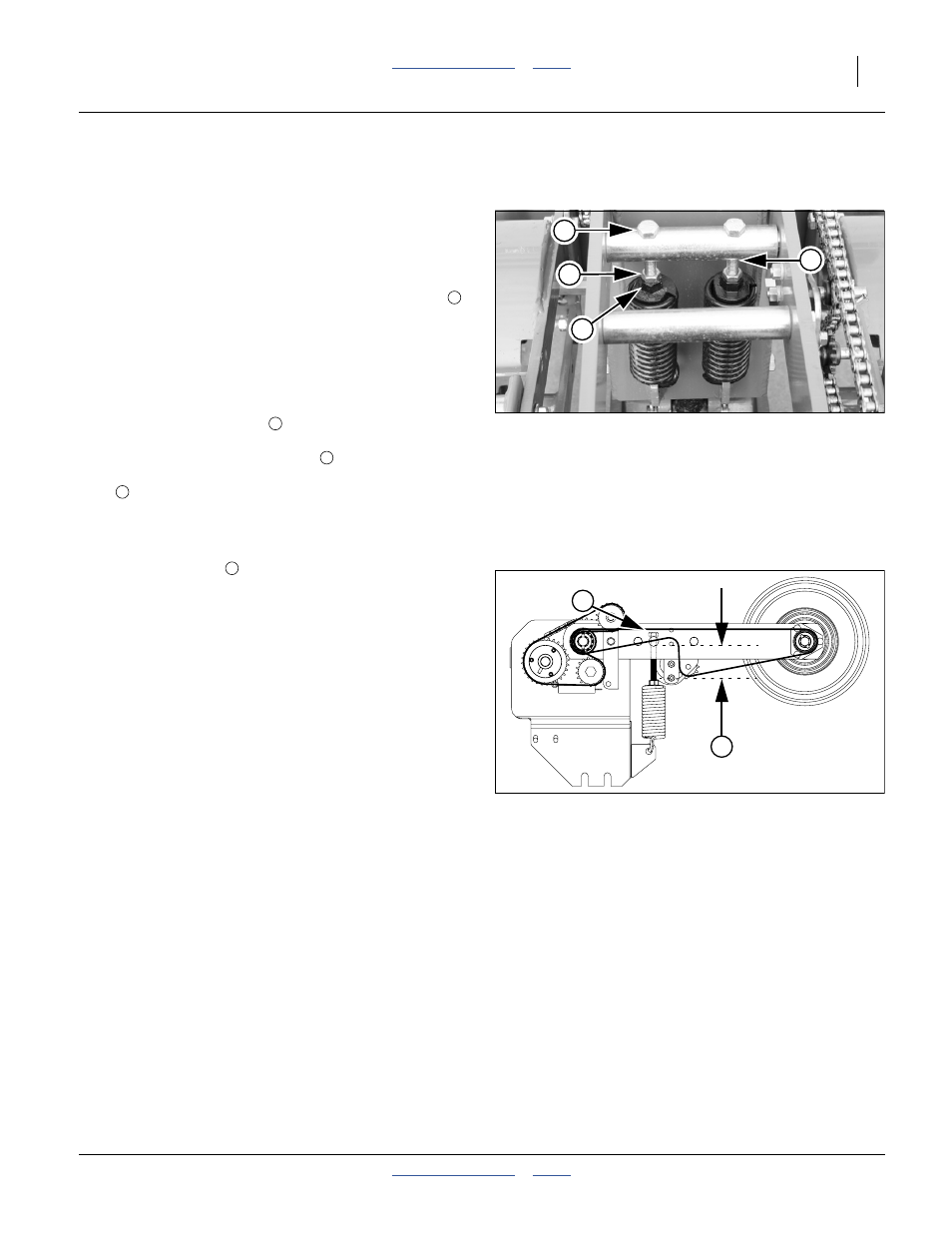

Contact Drive Tension

Refer to Figure 35 and Figure 36

Occasionally, due to planting height or planting

conditions, it may be necessary to adjust the spring

tension to keep the contact drive tire from slipping. For

example, if you experience low seeding rates in wet

conditions, it may be possible to compensate for this by

increasing contact drive tension, by tightening 4 bolts

(2 on each contact drive).

This is only effective if the ground drive wheels are not

themselves slipping excessively. The correct solution

may be to wait for drier planting conditions.

1.

Raise planter to ease adjustment.

2.

Check existing cast nut

position on all 4 bolts. The

factory setting, measured from the bottom

circumference of the cross bar

to the top of the

cast hex nut (not to the top of the jam nut) is:

25 mm and 32 mm (1 inch to 1

1

⁄

4

inch)

If the casting position is greater than this, return it to

factory setting and recheck field operation before

making further adjustments.

3.

Loosen jam nuts

.

4.

Turn bolts clockwise to increase contact drive

tension. The change in contact tension, per

revolution of the pair of bolt heads, is approximately:

3.3 kg/turn (7.3 pounds/turn)

5.

Recheck population (page 32) after adjusting.

Note: Do not use increased tension with under-inflated or

worn tires. The effective rolling radius of such tires

is reduced (increasing planting rate), and additional

contact drive tension cannot compensate for it.

Adjust tension until contact drive tire has enough tension

to stay in contact with gauge wheel.

Note: DO NOT increase tension so much that contact

drive tire resists turning.

Figure 35

Contact Drive Springs

25467

3

2

4

1

1

2

3

4

Figure 36

Contact Drive Tension

28134

4

1

4